Water container with rapid descaling function and gas steam furnace with water container

A gas steam, rapid technology, applied in the direction of the boiler cleaning device, etc., can solve the problems that the tank cannot be inspected and repaired, cannot be cleaned and maintained regularly, and achieves the effect of facilitating maintenance and increasing the arrangement distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

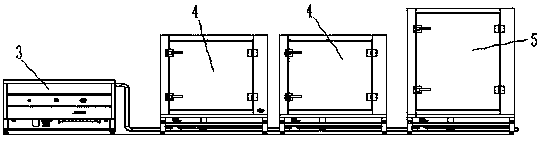

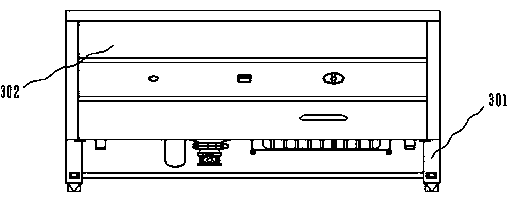

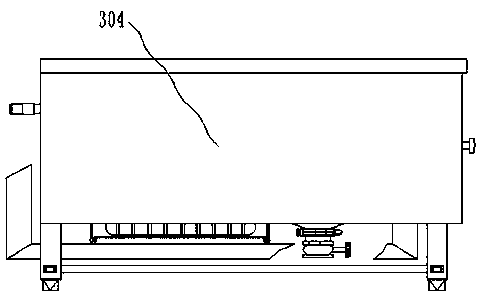

[0024] The appearance, structure, control system and working principle of the gas-fired steam furnace are the same as those of similar products. The burner heats the water tank to generate steam, and the induced draft fan is used to draw the negative pressure of the furnace to exhaust the smoke and the working mode of the automatic detection ignition system. Its special features Designed for water bladders.

[0025] A quick descaling water bladder 1 includes a water tank body 101 and a fire smoke pipe 102, which is characterized in that: the fire smoke pipe 102 is arranged in the middle of the water tank body 101, and the fire smoke pipe 102 is arranged in a multi-layer parallel insertion manner, running through The middle section of the slope of the water tank 101 and the side wall on one side of the water tank 101 increase the arrangement s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com