Light mixing module, display device adopting light mixing module, and design method of light mixing module

A module and light mixing technology, which is applied in identification devices, optics, light guides, etc., can solve the problem of uneven brightness of the light-emitting surface of the light mixing module, and achieve the effect of improving the dynamic display range, improving the display effect, and improving the manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

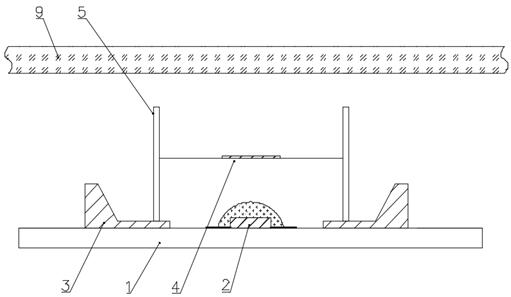

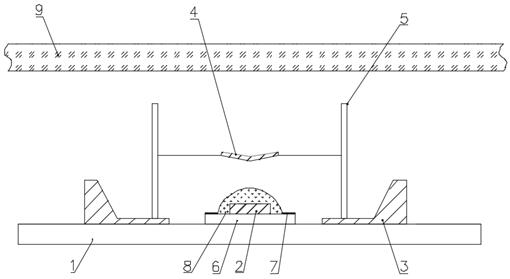

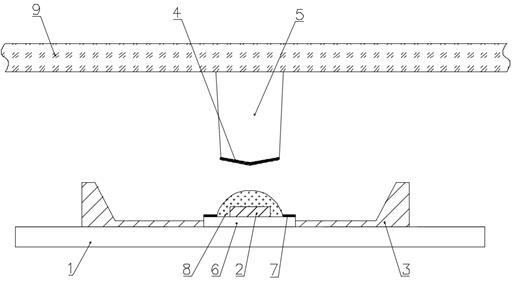

[0084] In this example, if figure 2 As shown, the LED chip 2 is indirectly mounted on the main substrate 1, specifically, the LED chip 2 is mounted on a sub-substrate 6, the sub-substrate 6 is mounted on the main substrate 1, and the sub-substrate 6 on the periphery of the LED chip 2 The surface is coated with a lower reflective layer 7, which is used to reflect the light incident on the substrate to the side of the light-emitting surface, so as to achieve the effect of mixing and filling light, and improve the utilization rate of light. In this embodiment, the width of the lower reflection layer is 0.5-1.5 mm. The LED chip 2 can be covered with an encapsulation layer 8, and the encapsulation layer 8 is arranged on the top and side walls of the LED chip to form a spherical package. The encapsulation layer 8 forms a spherical or rectangular transparent glue by means of molding and dispensing, which is conducive to the emission of light and facilitates more uniform mixing of l...

Embodiment 2

[0094] The structure of this embodiment is basically the same as that of Embodiment 1, including a main substrate 1 with a printed circuit, and at least one chip-level light-emitting unit arranged on the main substrate 1. The chip-level light-emitting unit includes an LED chip 2, a backlight bracket 3, and a light-shielding unit. The element 4 and the support element 5 have the same connection relationship, and the LED chip 2 is also covered with an encapsulation layer 8, the difference is that:

[0095] In this embodiment, the LED chip 2 is an RGB three-primary color chip, and the three three-primary color chips 21, 22, and 23 are jointly coated in the encapsulation layer 8, and the encapsulation layer 8 is preferably a transparent adhesive layer, that is, multiple LED chips are packaged The light source packaging unit formed after being put together.

[0096] In this example, D Z with D X The relationship satisfies the following conditions: D X Z X +2H Z *tan30°, and H ...

Embodiment 3

[0108] The present invention provides a method for quickly designing the light mixing module of the present invention, the steps of which are: 1.

[0109] S1: Determine the maximum value of DHR that the light mixing module needs to achieve: DHR MAX ;

[0110] S2: Select the LED chip specification of the chip-level light-emitting unit;

[0111] S3: Select the appropriate shading element specification for the chip-level light-emitting unit:

[0112] D. Z with D X The relationship satisfies the following conditions: D X Z X +2H Z *tan30°, and H Z 0.2 ~ 1mm, D X is the overall size of the LED chip and its encapsulation layer, H Z The distance between the lower surface of the shading element and the bottom surface of the LED chip, D Z is the width of the shading element in the horizontal direction;

[0113] got a D Z 、H Z size range;

[0114] S4: Calculate the specification parameters of the cup-shaped reflective surface of the backlight bracket:

[0115] S4.1: Fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com