Workpiece clamping device for cooling of small workpieces

A technology for small workpieces and workpiece clamps, applied in auxiliary devices, grinding/polishing safety devices, manufacturing tools, etc., can solve the problems of increased labor intensity, lack of practicability, increased production and processing time, etc. Convenience, increased functionality, increased friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

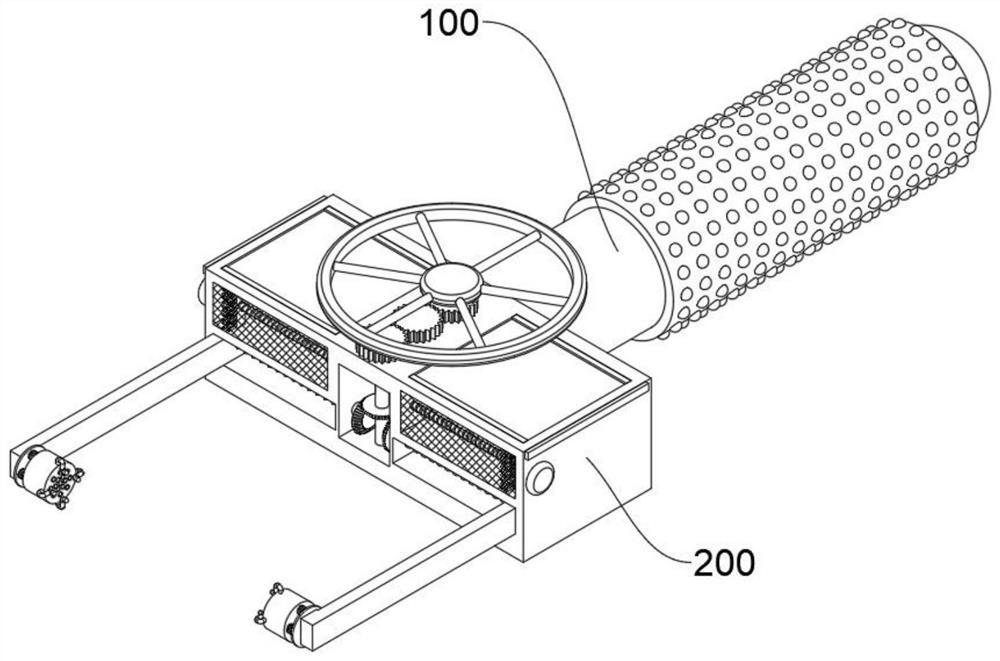

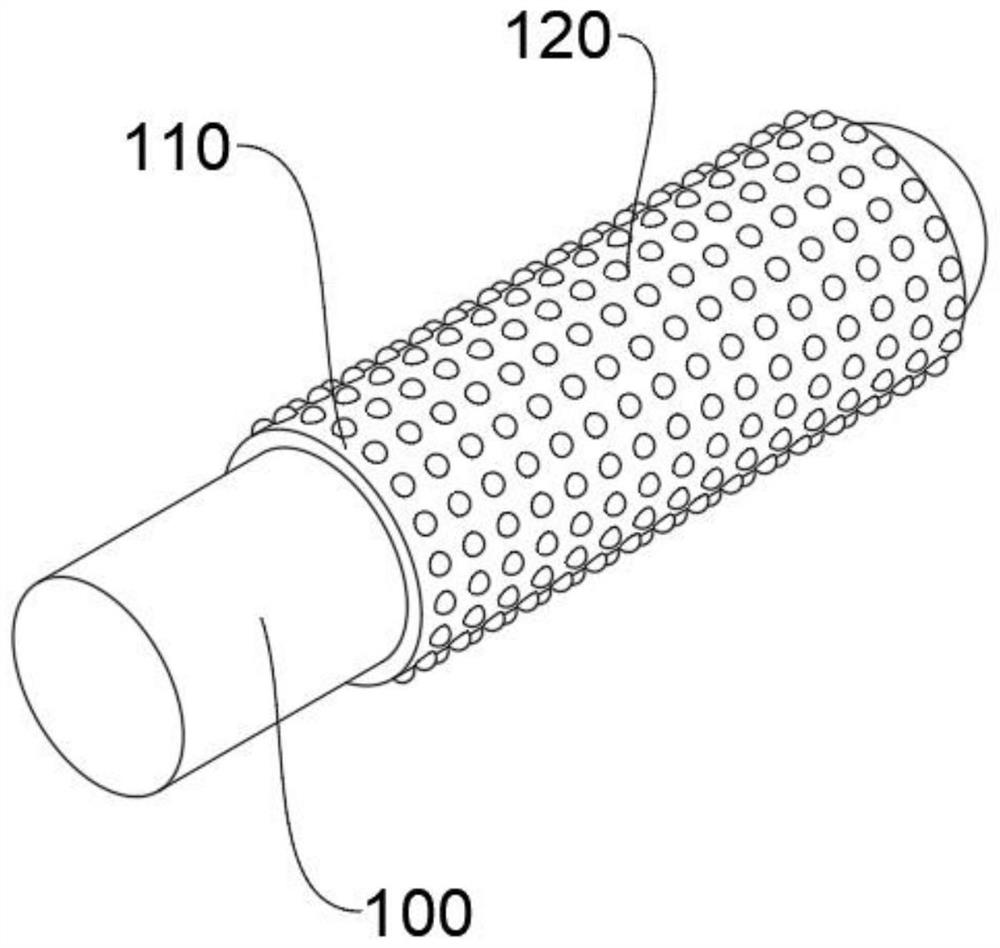

[0050] see Figure 1-Figure 16 As shown, this embodiment provides a workpiece clamping device for cooling small workpieces, including a handle 100 and a cooling clamping mechanism 200 provided at the end of the handle 100. The cooling clamping mechanism 200 includes at least:

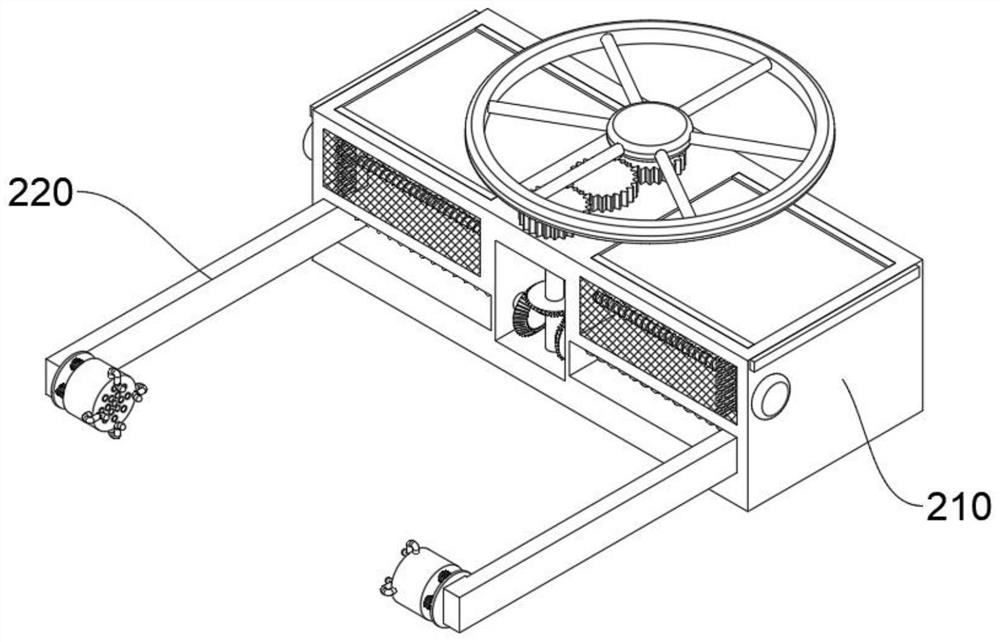

[0051] The fixed frame 210, the front surface of the fixed frame 210 is provided with two symmetrical moving grooves 211 near the bottom, the moving screw rod 212 is arranged to rotate inside the moving groove 211, and a power groove 213 is arranged between the two moving grooves 211, and the two moving grooves 211 The ends of the screw mandrel 212 are all rotated and stretched into the power groove 213 to be connected with a first bevel gear 2120. The power groove 213 is internally rotated to be provided with a rotating rod 2131, and the outer wall of the rotating rod 2131 is fixedly provided with a second bevel gear 2132. The outer wall of the bevel gear 2132 is meshed with the outer walls of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com