Brick pressing equipment for buildings

A technology for construction and bricks, applied in auxiliary forming equipment, manufacturing tools, forming indenters, etc., can solve problems such as low work efficiency, troublesome clay extrusion work, inconvenient removal of brick blanks, etc., to reduce workload and frequency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

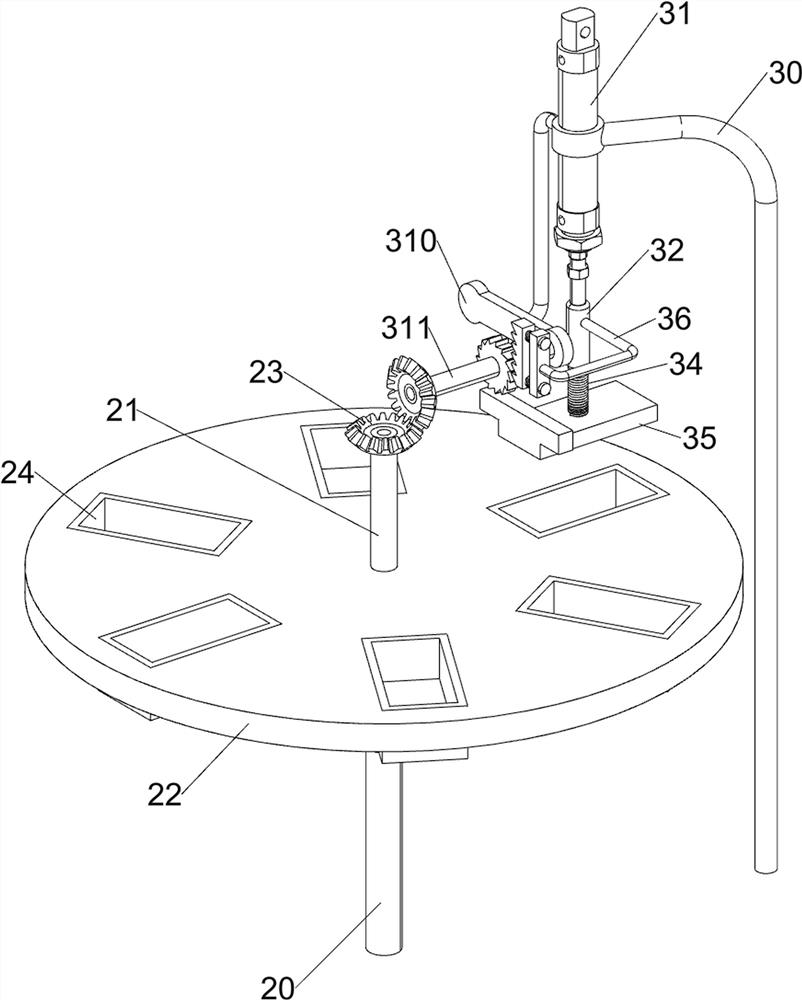

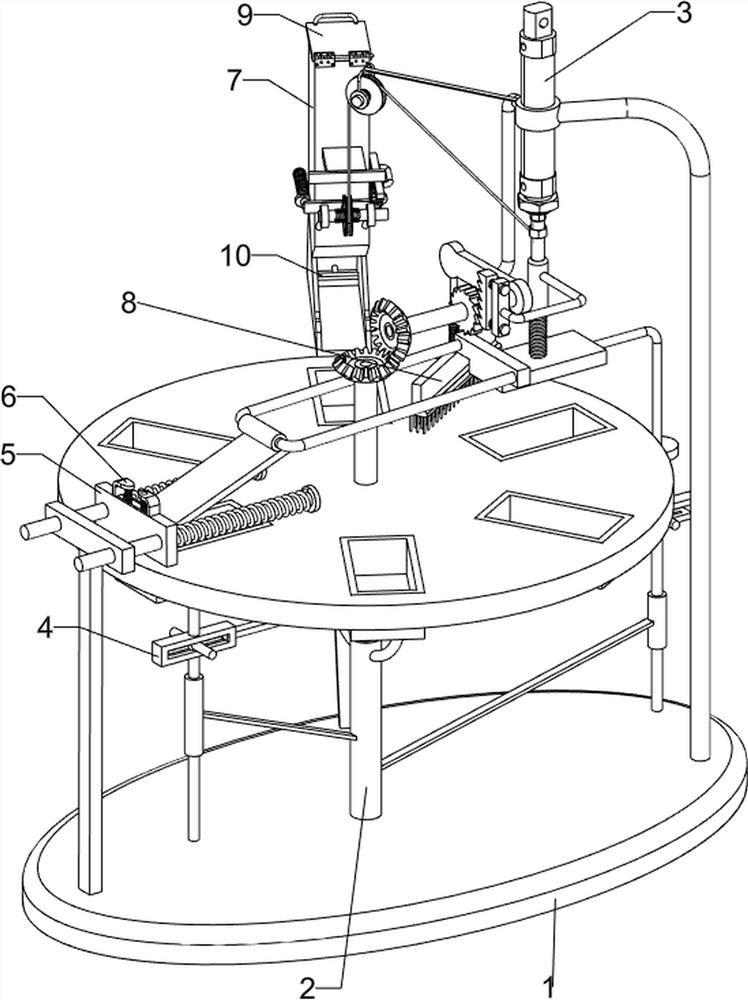

[0032] A device for pressing bricks for construction, such as Figure 1-3 As shown, it includes a base 1, a rotating mechanism 2 and a pressing mechanism 3, the middle part of the base 1 is provided with a rotating mechanism 2, and the right side of the base 1 is provided with a pressing mechanism 3.

[0033] When needing to carry out the brick pressing work, at first clay is placed on the rotating mechanism 2, then the pressing mechanism 3 is controlled to start working, the pressing mechanism 3 can suppress the clay on the rotating mechanism 2, and when the pressing is completed, press down The mechanism 3 will reset and drive the rotating mechanism 2 to rotate, so as to facilitate the pressing of the clay in the next place. At this time, the formed brick blank can be taken out. After all the clay has been pressed, it can be The pressing mechanism 3 can be controlled to stop working.

[0034] The rotating mechanism 2 includes a first bearing seat 20, a first rotating shaft ...

Embodiment 2

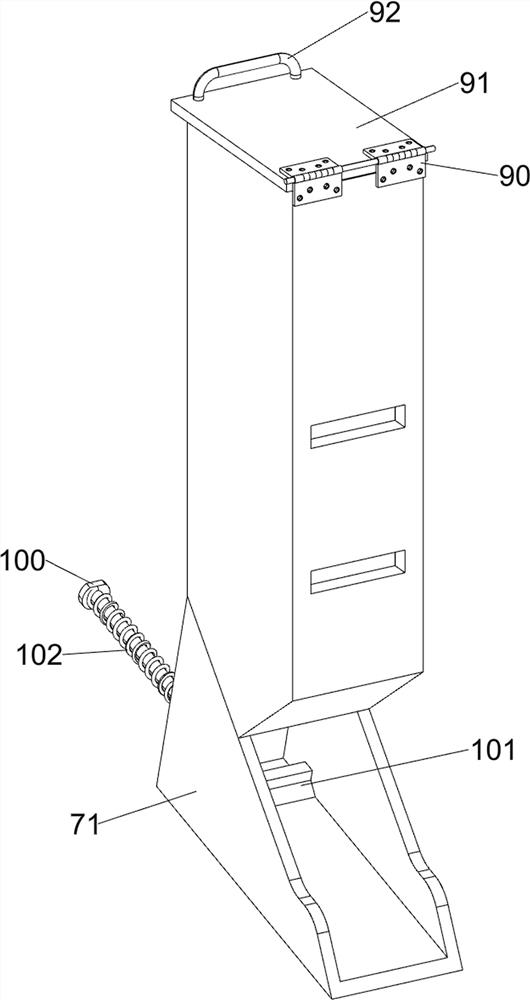

[0039] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, the ejection mechanism 4 is also included, and the ejection mechanism 4 includes a support rod 40, a fixed block 41, an oval ring 42, a first torsion spring 43, a second connecting rod 44, a slide rail 45, and a third connecting rod 46 , guide sleeve 47, pressure rod 48, limit sleeve 49 and limit rod 410, first rotating shaft 21 top, front and rear sides are all connected with support rod 40, support rod 40 tops are all connected with fixed block 41, between fixed block 41 The rotary type is provided with an elliptical ring 42, the first torsion spring 43 is connected between the elliptical ring 42 and the fixed block 41, the left and right sides of the elliptical ring 42 are connected with a second connecting rod 44, and the outside of the second connecting rod 44 is connected with a Slide rail 45, the bottom of slide rail 45 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com