White high-durability fair-faced concrete and preparation method thereof

A technology of fair-faced concrete and durability, applied in the field of cement concrete, can solve the problems of time-saving, labor-saving, material-saving, environmental protection, inability to take into account the high-durability appearance and color at the same time, and the loss of one-time pouring of fair-faced concrete. Eliminate appearance color difference, reduce appearance bubbles, and ensure the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

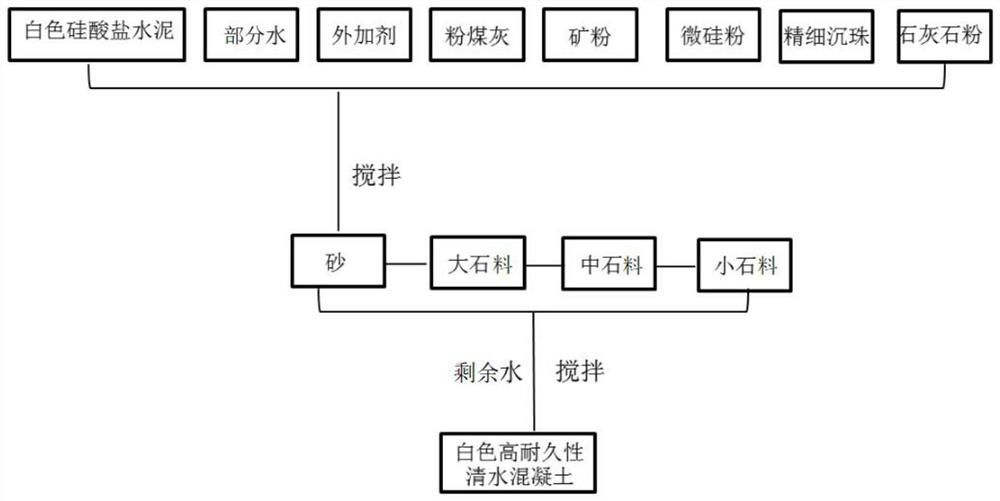

Method used

Image

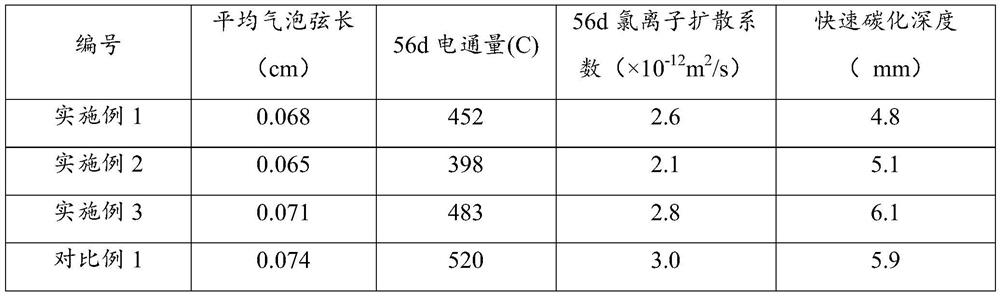

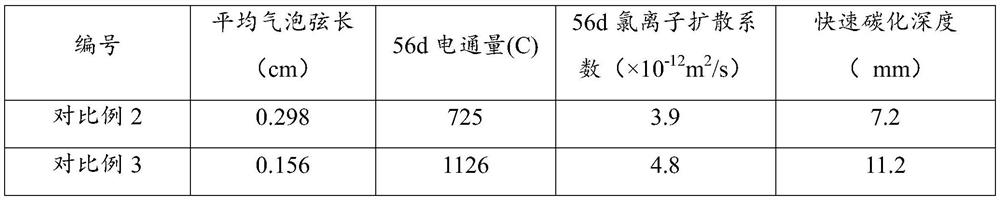

Examples

Embodiment 1

[0043] Weigh the corresponding white Portland cement 240kg / m according to the determined gradation 3 , Mineral powder 100kg / m 3 , fly ash 40kg / m 3 , Silica fume 24kg / m 3 , fine sinking beads 24kg / m 3 , limestone powder 24kg / m 3 , large stone 270kg / m 3 , Chinese stone 500kg / m 3 , small stone 270kg / m 3 , sand 650kg / m 3 , Admixture 3kg / m 3 , water 160kg / m 3 .

[0044] In this embodiment, a forced concrete mixer is preferably used to add the above-mentioned components according to the above-mentioned addition ratio, wherein, the following mixing process is divided into two feedings, specifically, white Portland cement, 70% Water, admixture, mineral powder, sand, fly ash, micro silica fume, fine sinking beads and limestone powder, after stirring for 10-20s, put in large stone, medium stone, small stone and sand, continue stirring for 15-20s, then put in For the remaining 30% of water, the total mixing time is 150s.

Embodiment 2

[0046] Weigh the corresponding white Portland cement 260kg / m according to the determined gradation 3 , Mineral powder 110kg / m 3 , fly ash 50kg / m 3 , Silica fume 50kg / m 3 , fine sinking beads 35kg / m 3 , limestone powder 35kg / m 3 , large stone 285kg / m 3 , Chinese stone 520kg / m 3, small stone 285kg / m 3 , sand 675kg / m 3 , Admixture 3.5kg / m 3 , water 180kg / m 3 .

[0047] In this embodiment, a forced concrete mixer is preferably used to add the above-mentioned components according to the above-mentioned addition ratio, wherein, the following mixing process is divided into two feedings, specifically, white Portland cement, 70% Water, admixture, mineral powder, sand, fly ash, micro silica fume, fine beads, limestone powder, after stirring for 10-20s, put in large stone, medium stone, small stone and sand, continue stirring for 15-20s, then put in the remaining 30% of water, where the total mixing time is 160s.

Embodiment 3

[0049] Weigh the corresponding white Portland cement 280kg / m according to the determined gradation 3 , Mineral powder 120kg / m 3 , fly ash 60kg / m 3 , Silica fume 70kg / m 3 , fine sinking beads 45kg / m 3 , limestone powder 45kg / m 3 , large stone 300kg / m 3 , Chinese stone 540kg / m 3 , small stone 300kg / m 3 , sand 700kg / m 3 , Admixture 4.5kg / m 3 , water 240kg / m 3 .

[0050] In this embodiment, a forced concrete mixer is preferably used to add the above-mentioned components according to the above-mentioned addition ratio, wherein, the following mixing process is divided into two feedings, specifically, white Portland cement, 70% Water, admixture, mineral powder, sand, fly ash, micro silica fume, fine beads, limestone powder, after stirring for 10-20s, put in large stone, medium stone, small stone and sand, continue stirring for 15-20s, then put in the remaining 30% of water, where the total mixing time is 160s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com