Pipeline joint device capable of achieving multi-degree-of-freedom active adjustment and butt joint

An active adjustment, pipe joint technology, applied in the direction of pipes/pipe joints/fittings, expansion compensation devices for pipelines, pipe supports, etc., can solve installation, construction inconvenience, sleeve stuck, small axial compensation, etc. problems, to achieve the effect of saving time and materials, stable structure, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

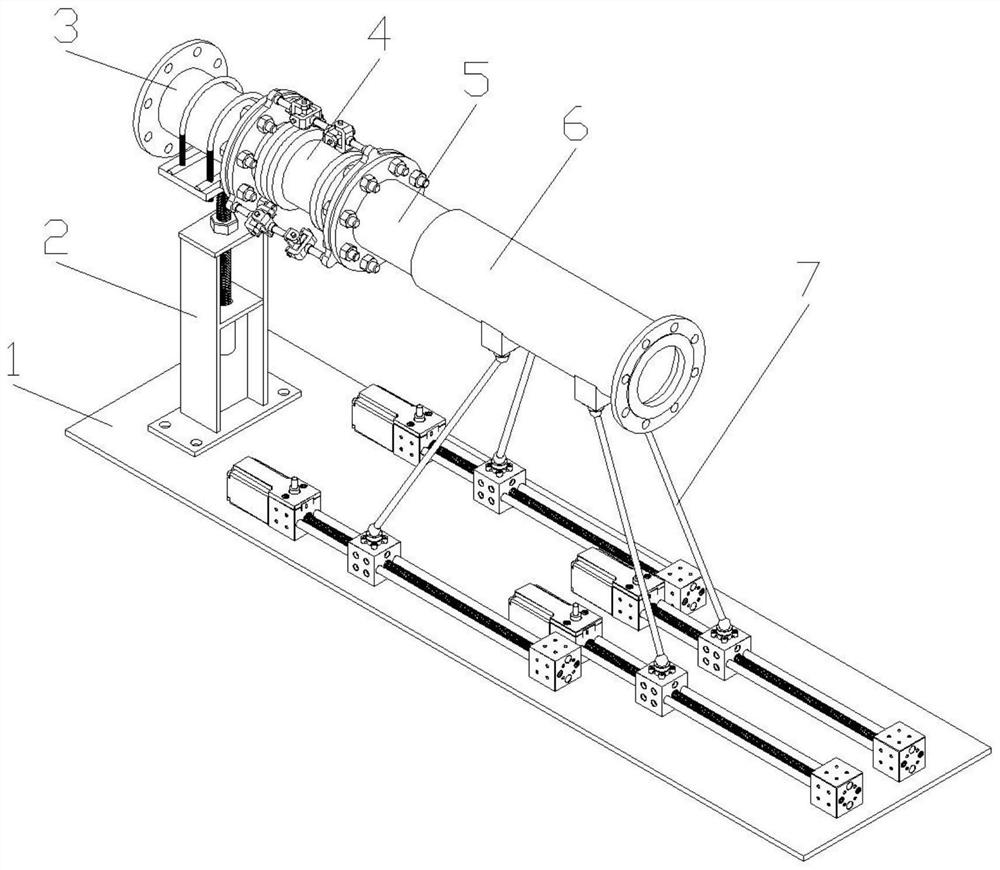

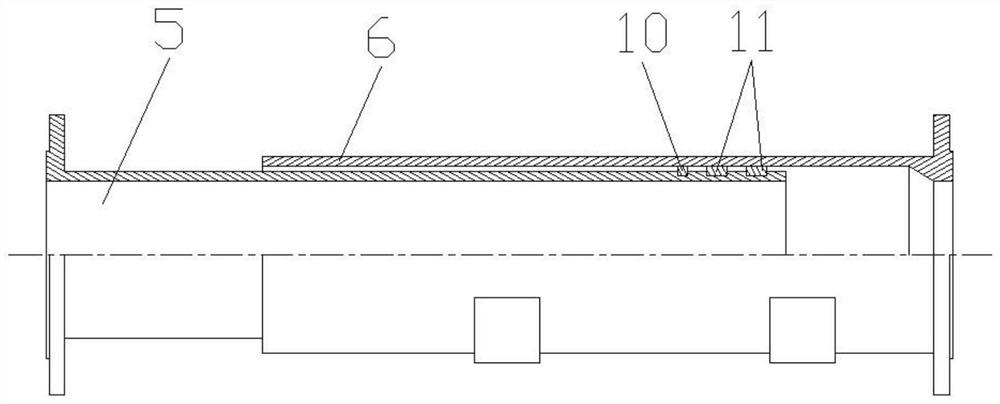

[0049] Figure 5a-5c It is a schematic diagram of axial displacement based on the device of the present invention, Figure 5a In the initial state, the four slide blocks move axially to the right simultaneously, and then drive the outer casing 6 to move axially to the right, which is convenient to be connected with the outer casing 6 and the connecting pipe on the right side.

Embodiment 2

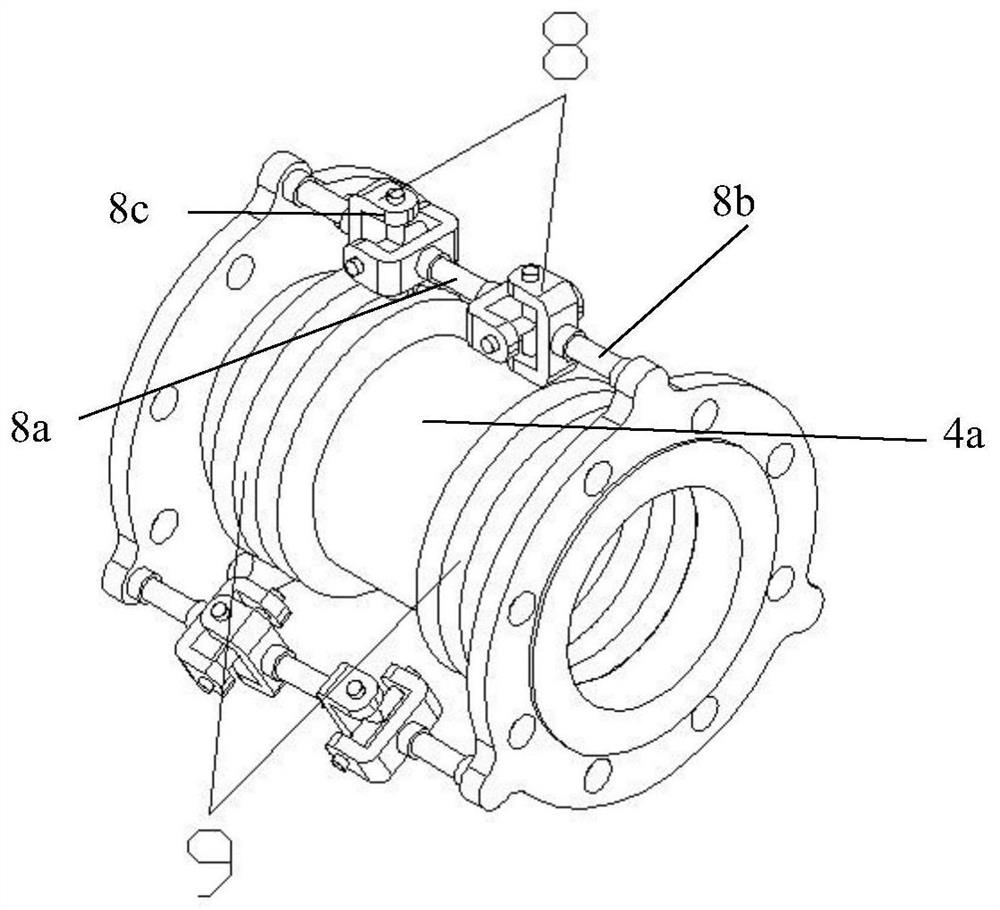

[0051] Figure 6a-Figure 6c It is a schematic diagram of radial (vertical) displacement based on the device of the present invention, Figure 6a is the initial state. In some scenarios, the height of the outer sleeve 6 needs to be raised or lowered to connect with the connecting pipe. At this time, we control the corresponding slider of the support adjustment device 7 to slide to the corresponding position, so that the height of the outer sleeve 6 is raised. Or drop; in the process of raising / falling the height of the outer casing 6, the bellows 9 at both ends of the radial compensator 4 are deformed and the universal joint regulator 8 ensures the fixed connection of the flanges on both sides, ensuring that the straight pipe connecting pipe 3 and The inner tube 5 is always tightly connected.

Embodiment 3

[0053] Figure 7a-Figure 7c It is a schematic diagram of radial (horizontal) displacement of the device of the present invention, Figure 7a is the initial state, in some scenarios, it is necessary to move the outer sleeve 6 forward or backward radially and connect it to the connecting pipe. At this time, we control the corresponding slider of the support adjustment device 7 to slide to the corresponding position to realize The outer sleeve 6 moves radially forward or backward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com