high pressure water supply pipe

A high-pressure water supply and water pipe technology, applied in the direction of pipe components, water saving, pipes/pipe joints/pipe fittings, etc., can solve the problems of difficulty in finding the blocked position of the water supply pipe, the influence of the normal operation of the pipe, and the inability of the water supply pipe to actively clean up impurities, etc. Convenient and flexible dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

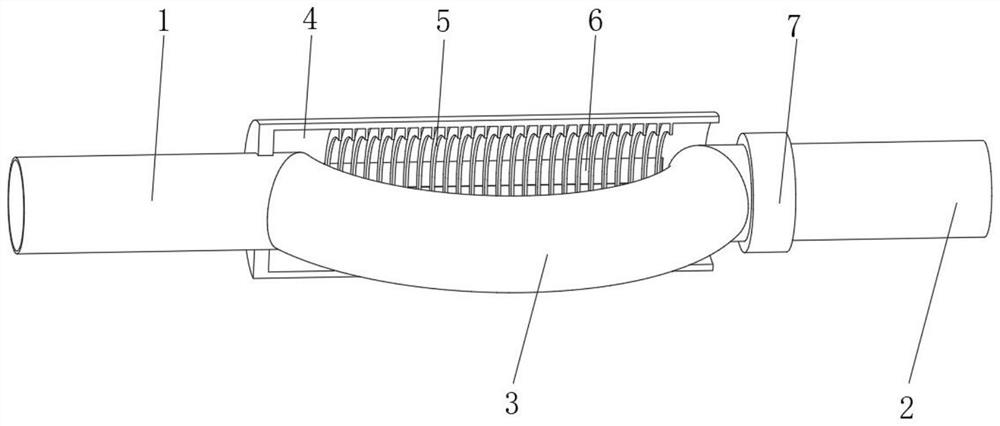

[0037] like Figure 1-3As shown, the present invention provides a technical solution: a high-pressure water supply pipe, including a liquid inlet pipe 1 and a liquid outlet pipe 2, and a corrugated conduction mechanism 3 is fixedly connected to the position between the liquid inlet pipe 1 and the liquid outlet pipe 2. A limiting storage frame 4 is fixedly connected to the outside of the liquid pipe 1 and close to one end of the corrugated conducting mechanism 3 , the inner surface of the limiting storage frame 4 is evenly and fixedly connected with a limiting clip 5 , and the middle position inside the limiting storage frame 4 is fixedly connected with a transmission magnet block 6 . , one end of the liquid outlet pipe 2 close to the corrugated conduction mechanism 3 is fixedly connected with an active dredging mechanism 7;

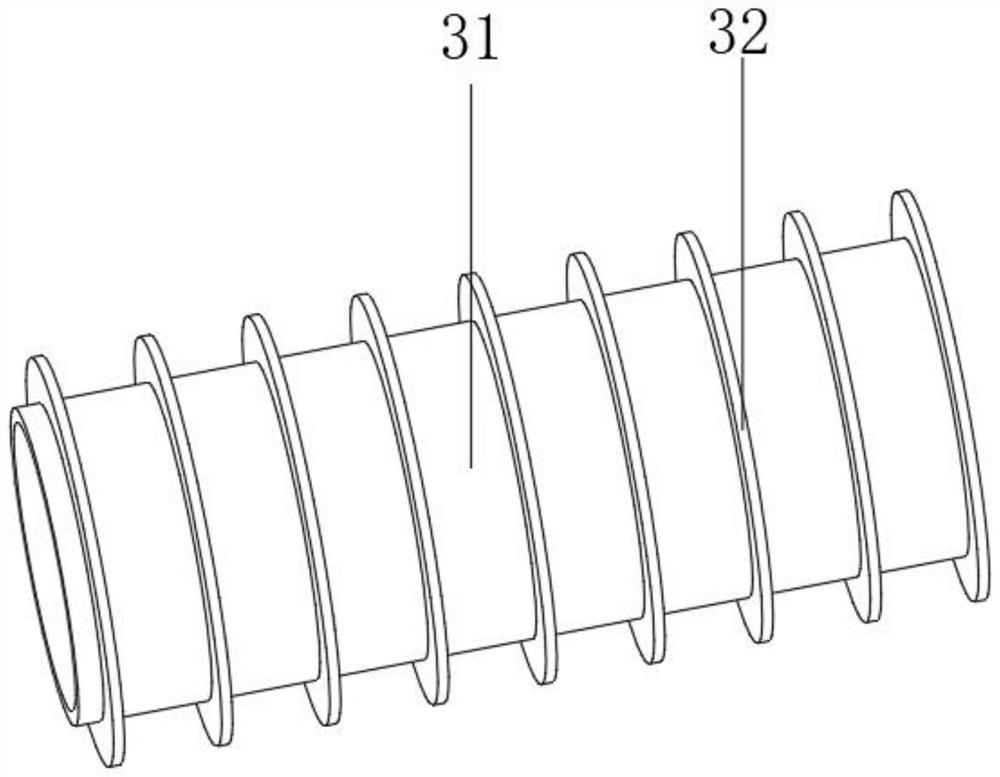

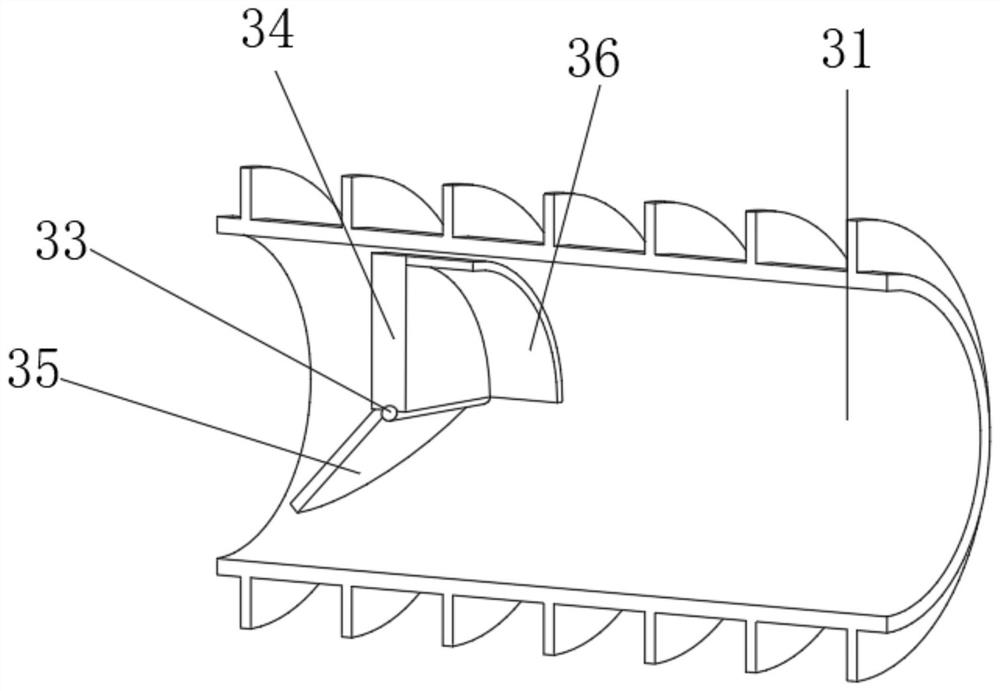

[0038] The corrugated transmission mechanism 3 includes a corrugated telescopic rod 31, two ends of the corrugated telescopic rod 31 are respectively com...

Embodiment 2

[0042] like Figure 4-5 As shown, on the basis of the first embodiment, the present invention provides a technical solution: a high-pressure water supply pipe, the active dredging mechanism 7 includes a dredging inner pipe 71, which is fixedly connected inside the inner pipe 71 and close to the corrugated conduction mechanism 3 There is an auxiliary filter assembly 72 , a moving chute 73 is fixedly connected to the inner side of the dredging inner pipe 71 , and a support sliding rod 74 is slidably connected to the inside of the moving chute 73 .

[0043] A negative pressure baffle 75 is fixedly connected to one end of the supporting slide bar 74 away from the moving chute 73 , and an auxiliary rejecting component 76 is evenly and fixedly connected to the surface of the negative pressure baffle 75 away from the supporting slide bar 74 . Realize the active filtration and collection of impurities in the pipeline, which is convenient for workers to find the blockage position.

Embodiment 3

[0045] like Image 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a high-pressure water supply pipe, the auxiliary filter assembly 72 includes an auxiliary blocking rod 721, and a shovel is fixedly connected to the right side of the auxiliary blocking rod 721 The material cone rod 722 and the shovel cone rod 722 are arranged corresponding to the negative pressure baffle 75 .

[0046] The vertical positions inside the auxiliary blocking rod 721 are uniformly provided with filter blocking grooves 723 , and reverse cutting hooks 724 are fixedly connected to the upper and lower ends of the filter blocking groove 723 . Under the action of the extrusion force, the impurities are cut off, the particle size of the impurities is reduced, the active chopping of the impurities is realized, and the impurities are prevented from being blocked again in the downstream.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com