Medium heating device for testing military parts

A technology for medium heating and components, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of volume and cost increase, low work efficiency, polluted medium, etc., and achieve volume and cost reduction , Avoid temperature instability and increase heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

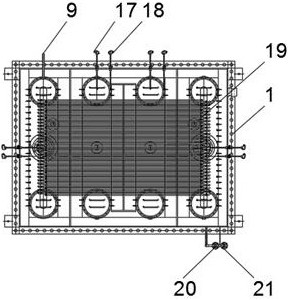

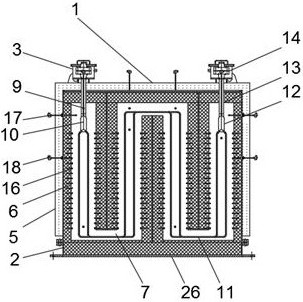

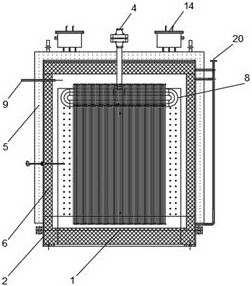

[0018] By the following Figure 1-4 Detailed description of the specific embodiments of the present invention will be described in detail.

[0019] Embodiment figure 1 , figure 2 , image 3 with Figure 4 It is given, the present invention includes a furnace body 1, an outer side of the furnace body 1 is provided, and the inside of the furnace body housing 2 is provided with a heating chamber 7, and one side of the top end of the furnace body 1 is provided with a first junction box 3, a furnace a central top body 4 is provided with a medium inlet, a medium inlet of the first terminal box 4 through the bottom end 3 of the furnace body 1 is connected to a first air manifold 8, 7 at a position corresponding to the upper heating chamber of the furnace body 1 is provided with a protective gas inlet 9. The other end of the heating chamber 7 is provided with a protective gas outlet 20. The bottom end of the first total air tube 8 is connected to the branch pipe 11, and the branch tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com