Switch cabinet group

A switchgear and cabinet technology, applied in the direction of switchgear, switchgear setting, substation/switch layout details, etc., can solve the problems of main busbar error, difficult fixed connection, etc., and achieve simple tightening method, simple structure, Guaranteed flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

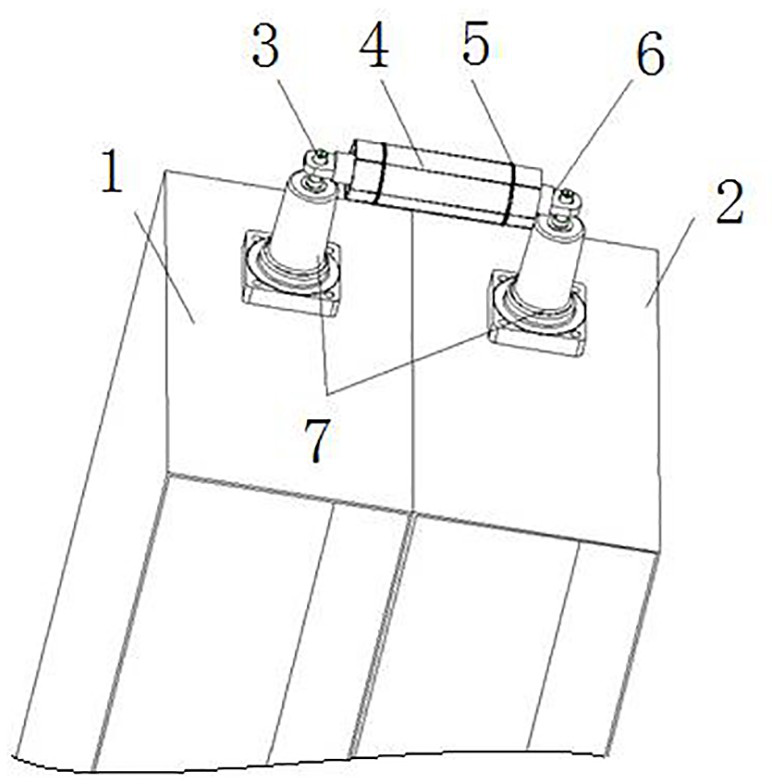

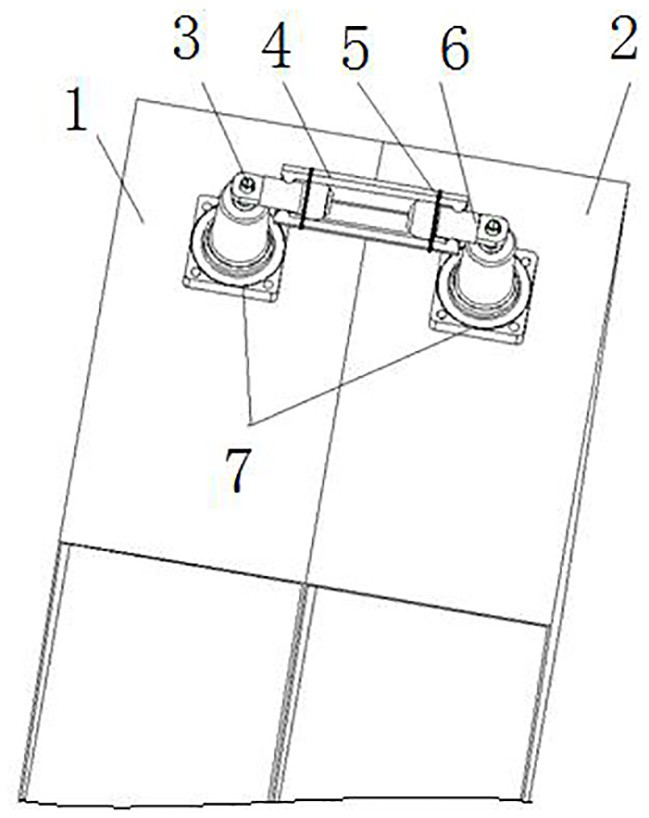

[0034] Such as figure 1 As shown, the switchgear group includes a left cabinet unit 1 and a right cabinet unit 2 arranged along the left and right directions. Insulators 7 are fixed on the top walls of the two cabinet units, and a conductive telescopic panel is provided between the two insulators 7. structure. In this embodiment, the conductive telescopic structure is a sleeve-type telescopic structure, which increases the conductive contact area and ensures the flow rate. Of course, in other embodiments, it may also be a guide groove telescopic structure.

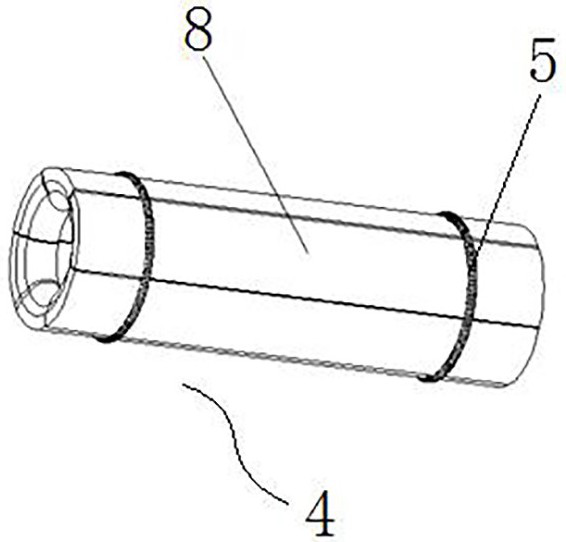

[0035] Such as figure 1 , figure 2 and Figure 4 As shown, the sleeve-type telescopic structure includes a conductive sleeve 4 and two conductive rods 6. The two conductive rods 6 are respectively located at both ends of the conductive sleeve 4 and are slidably fitted in the conductive sleeve 4. The conductive rod on the left side The left end of 6 is fixed on the insulator 7 of the left cabinet unit 1 through the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com