Bamboo casing pile combined with electroosmosis to strengthen soft soil subgrade system and construction method

A technology of soft soil roadbed and casing, which is applied in the direction of foundation structure engineering, sheet pile wall, soil protection, etc. It can solve the problems of rising project cost, low side friction resistance, floating, tilting, etc., and achieves the improvement of pile body friction Effects of resistance, increased friction, and increased interface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

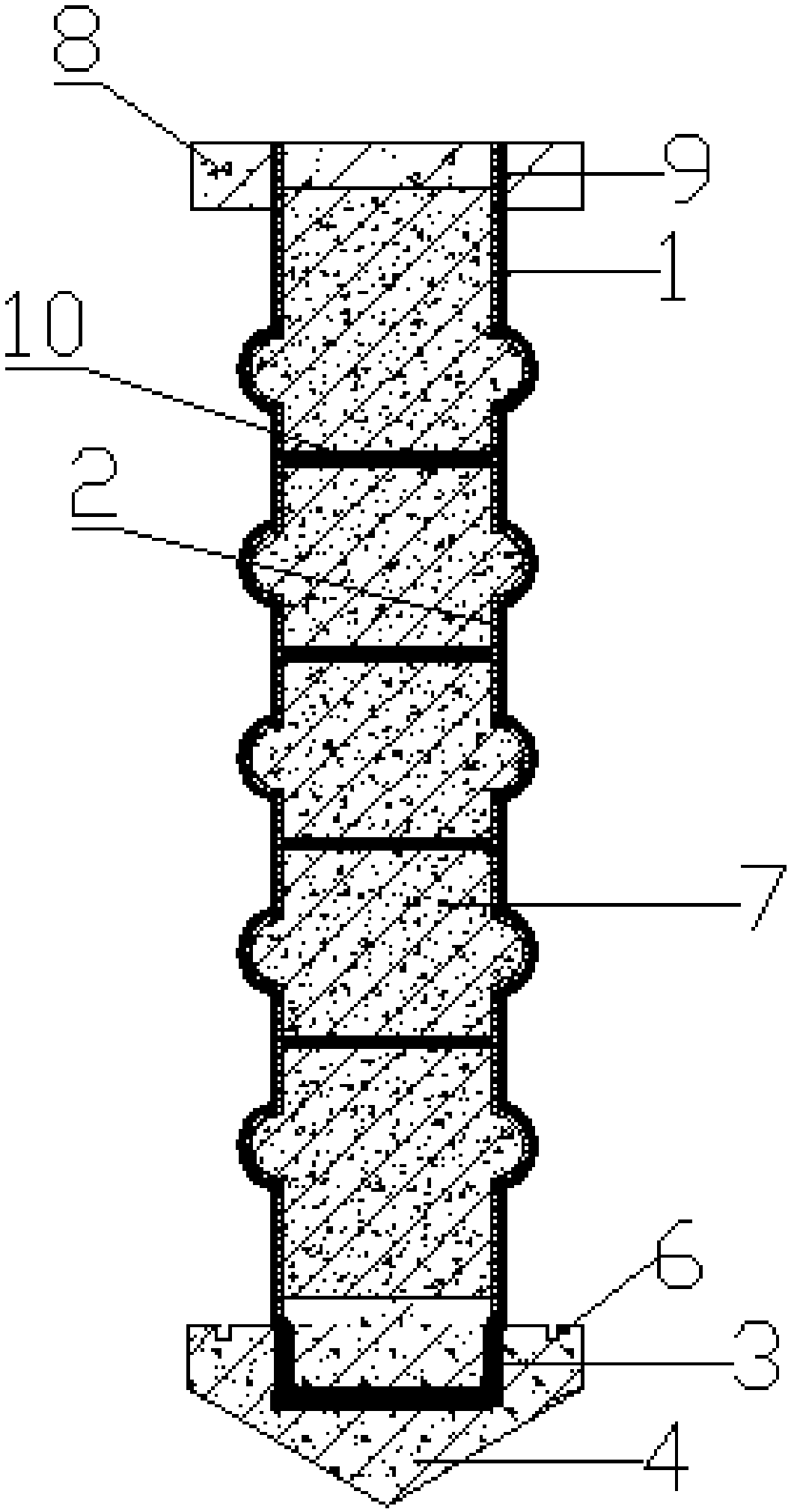

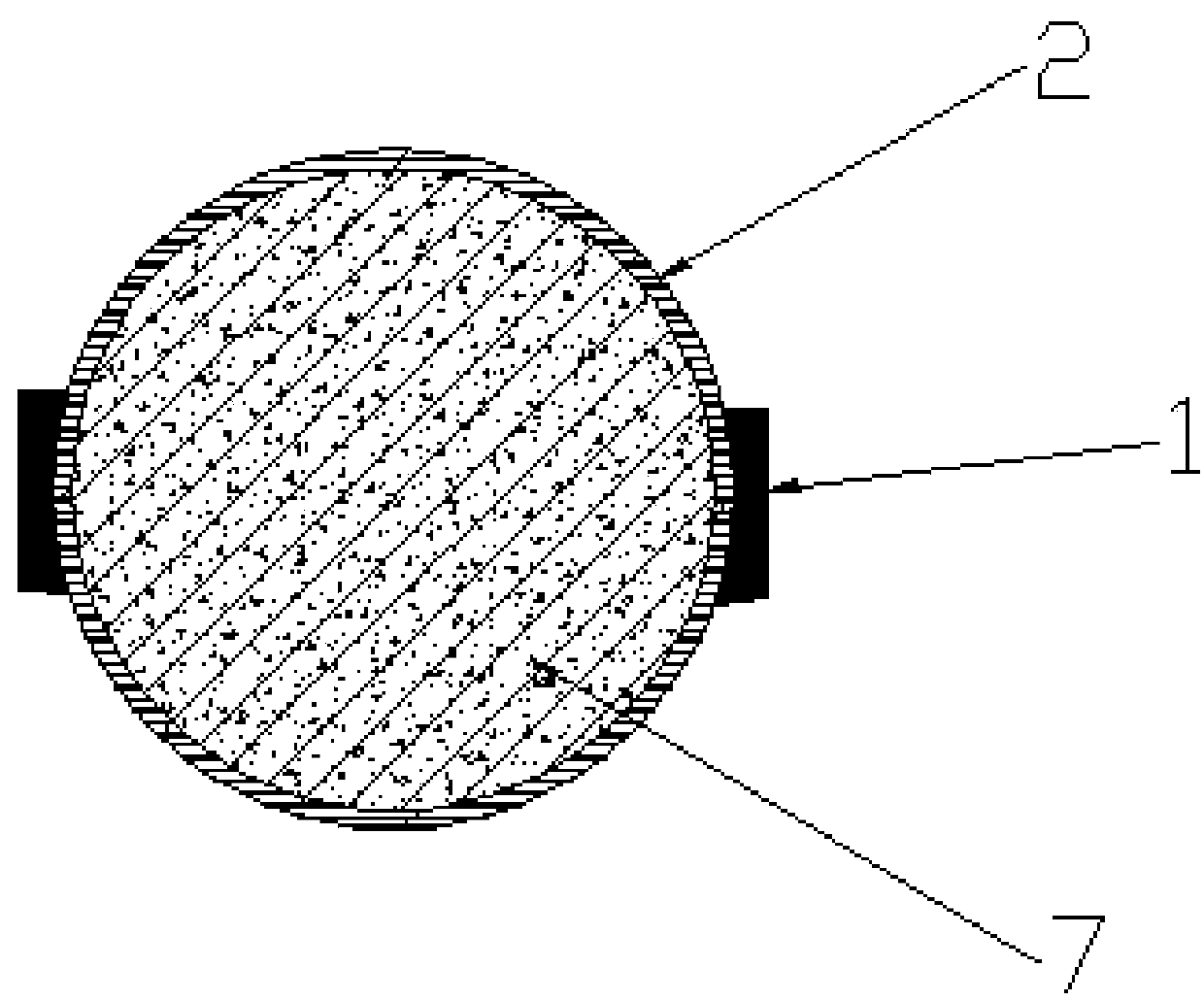

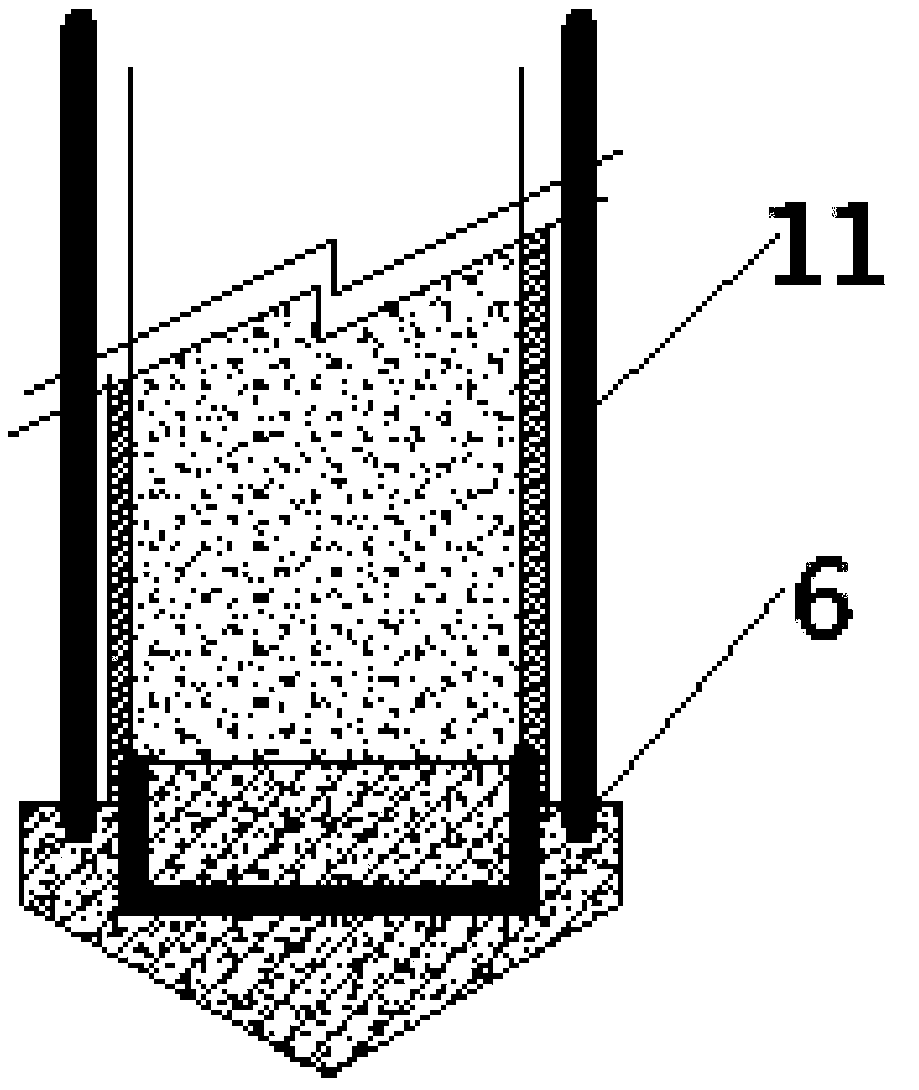

[0036] Such as figure 1 As shown, the conductive plastic drainage board 1 is 10cm wide, and the conductive plastic drainage board 1 is tightly bonded to the bamboo sleeve 2 by using epoxy resin as an adhesive. The diameter of the bamboo sleeve 2 is made according to the design requirements, generally 15cm -20cm, two conductive plastic drainage boards 1 are arranged evenly along the vertical direction. The bottom of the conductive plastic drainage board 1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com