Electrical cabinet capable of automatically cleaning dust screen

A technology for automatic cleaning and electrical cabinets, applied in the field of electrical cabinets, can solve the problems of easily damaged components, time-consuming and labor-consuming, and heavy cleaning workload, and achieve the effect of protecting components and facilitating absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

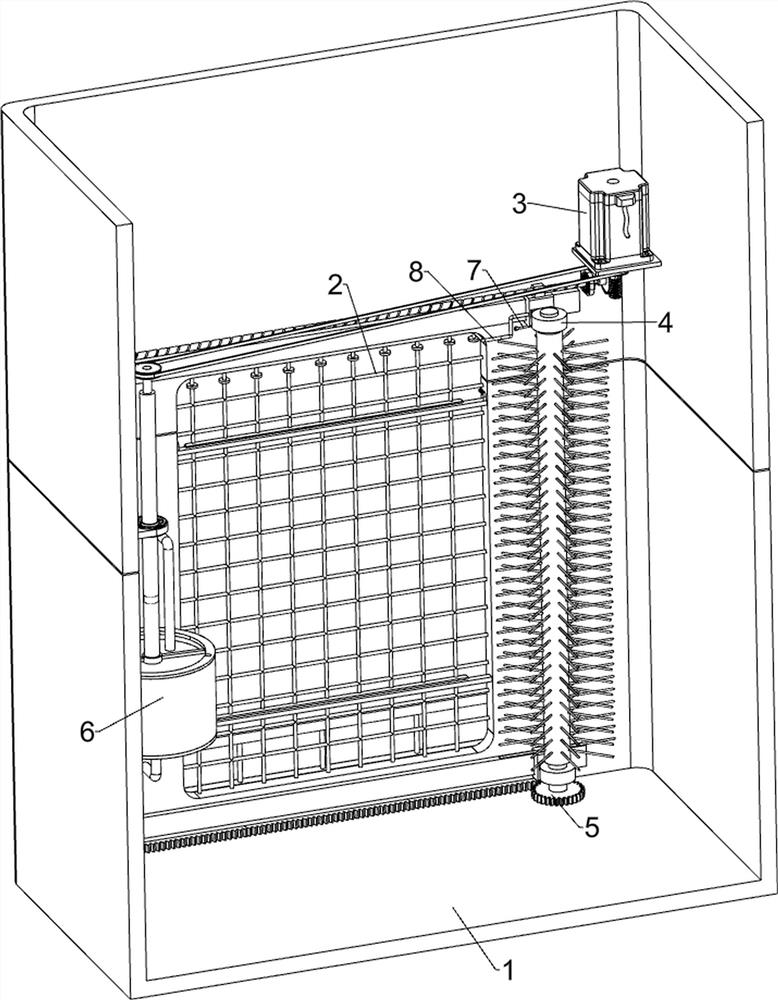

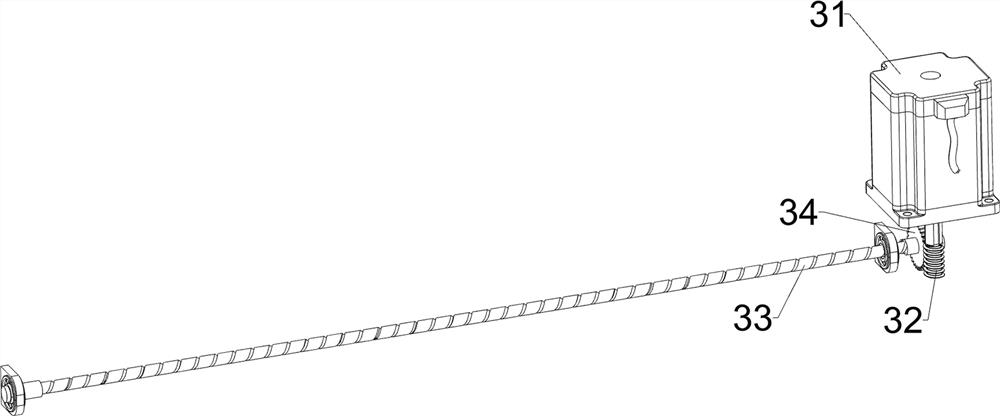

[0031] An electrical cabinet that can automatically clean the dust-proof net, such as Figure 1 to Figure 4 As shown, it includes an electrical cabinet body 1, an electrical cabinet dust-proof net 2, a moving component 3 and a cleaning component 4. The rear side of the electrical cabinet body 1 is slidingly provided with an electrical cabinet dust-proof net 2, and the rear side of the electrical cabinet body 1 is A moving assembly 3 is provided on the side, and a cleaning assembly 4 is provided on the inner rear side of the electrical cabinet body 1 .

[0032] When it is necessary to clean the dust-proof net on the electrical cabinet, start the mobile component 3 to make the cleaning component 4 operate, and then the cleaning component 4 cleans the dust-proof net 2 of the electrical cabinet. When the dust-proof net 2 of the electrical cabinet is cleaned, The moving assembly 3 is controlled to reset each assembly, and then the moving assembly 3 is closed to stop the operation o...

Embodiment 2

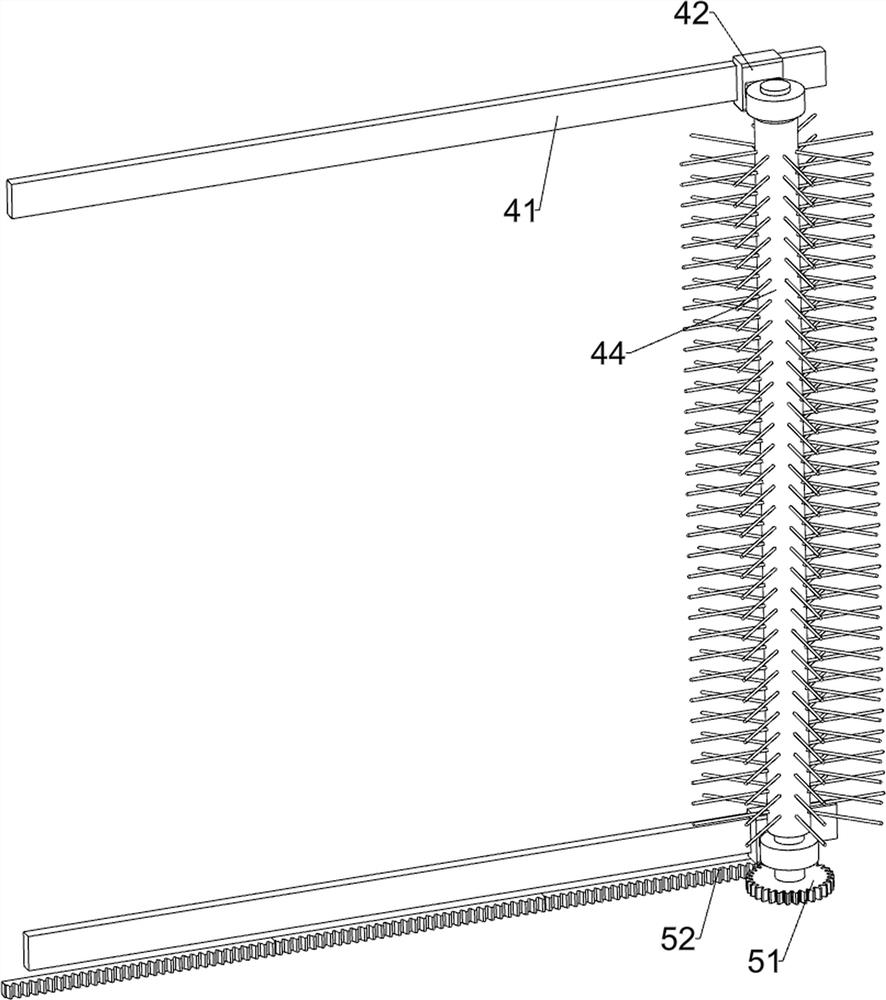

[0038] On the basis of Example 1, such as figure 2 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 and Figure 11 As shown, a rotating assembly 5 is also included. The rotating assembly 5 includes a gear 51 and a rack 52. The lower side of the roller brush 44 is connected with a gear 51. The inner lower side of the electrical cabinet body 1 is provided with a rack 52. The rack 52 Mesh with gear 51.

[0039] When the rolling brush 44 moves, the gear 51 is then moved, and the gear 51 is rotated due to the action of the rack 52, and then the rolling brush 44 is driven to rotate, so that the cleaning of the dustproof net 2 of the electrical cabinet by the rolling brush 44 is better. clean.

[0040] Also includes a dust suction assembly 6, the dust suction assembly 6 includes a rotating shaft 61, a transmission pulley set 62, a dust suction cover 63, a hose 64, a cover 65 and blades 66, and the left side of the electrical cabinet body 1 is rotated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com