Device for adjusting rotatble milling spindle of edge milling machine, and edge milling machine

A milling cutter bar, rotary technology, applied in milling machine equipment, machine tool parts, details of milling machine equipment, etc., to achieve the effect of improving reading accuracy, simple adjustment, and comfortable device operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

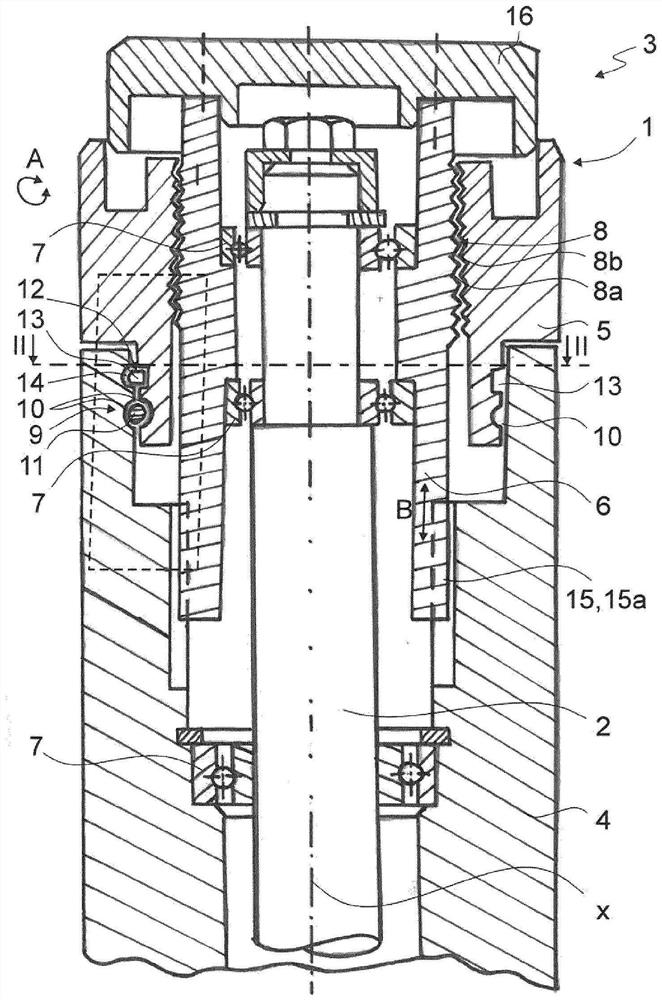

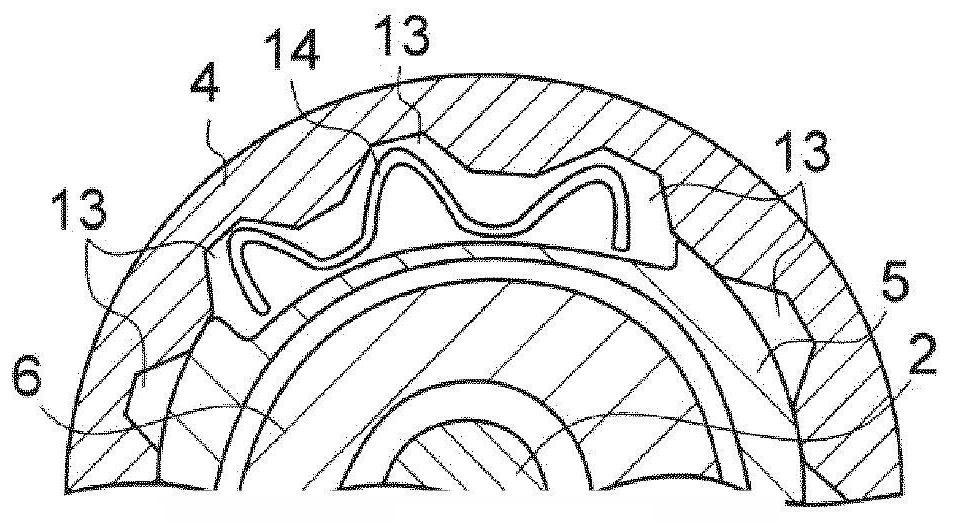

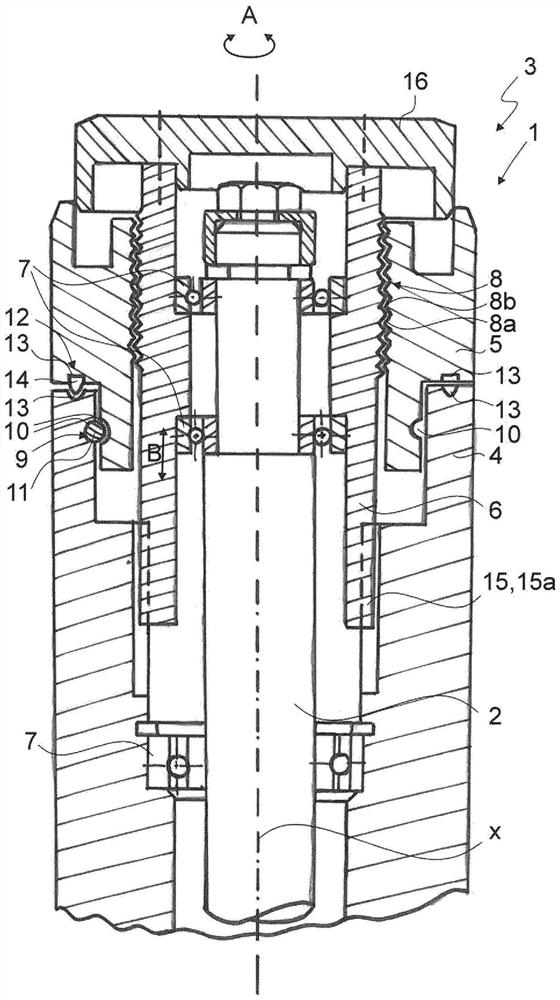

[0043] figure 1 A device 1 for adjusting a rotatable milling tool bar 2 of a milling machine 3 along the longitudinal axis x of the milling tool bar 2 is shown. The device 1 has, in particular, a body 4 , an actuating element 5 , which is rotatable according to arrow A, and an adjusting element 6 . To adjust the milling rod 2 , the adjusting element 6 acts on the milling rod 2 in the direction of the longitudinal axis x, so that a movement of the adjusting element 6 along the longitudinal axis x according to the arrow B causes a corresponding movement of the milling rod 2 . In the present case, the milling cutter bar 2 is mounted on the adjustment part 6 by means of a plurality of supports 7, so that the described coupling of the two components is ensured.

[0044]The operating member 5 is coupled to the adjusting member 6 such that a rotation of the operating member 5 about the longitudinal axis x according to arrow A causes the adjusting member 6 to move according to arrow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com