Melon and fruit picking mechanical equipment

A kind of mechanical equipment and melon and fruit technology, applied in the field of melon and fruit picking machinery and equipment, can solve the problems of picking personnel inconvenience, deformation of ripe persimmons, and damage of ripe persimmons, so as to improve picking efficiency, improve protection, reduce stability and danger Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

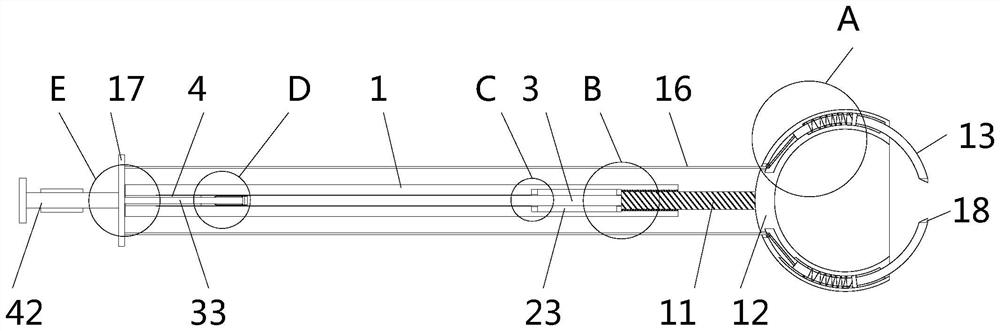

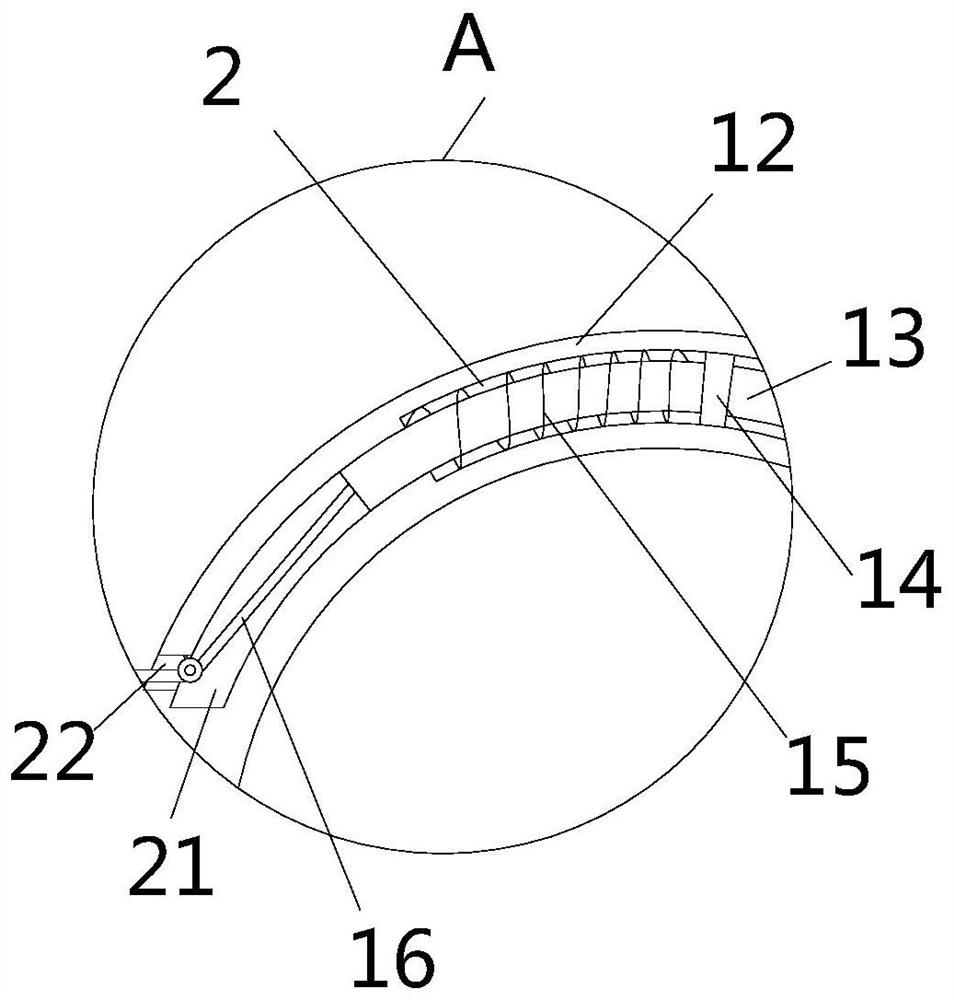

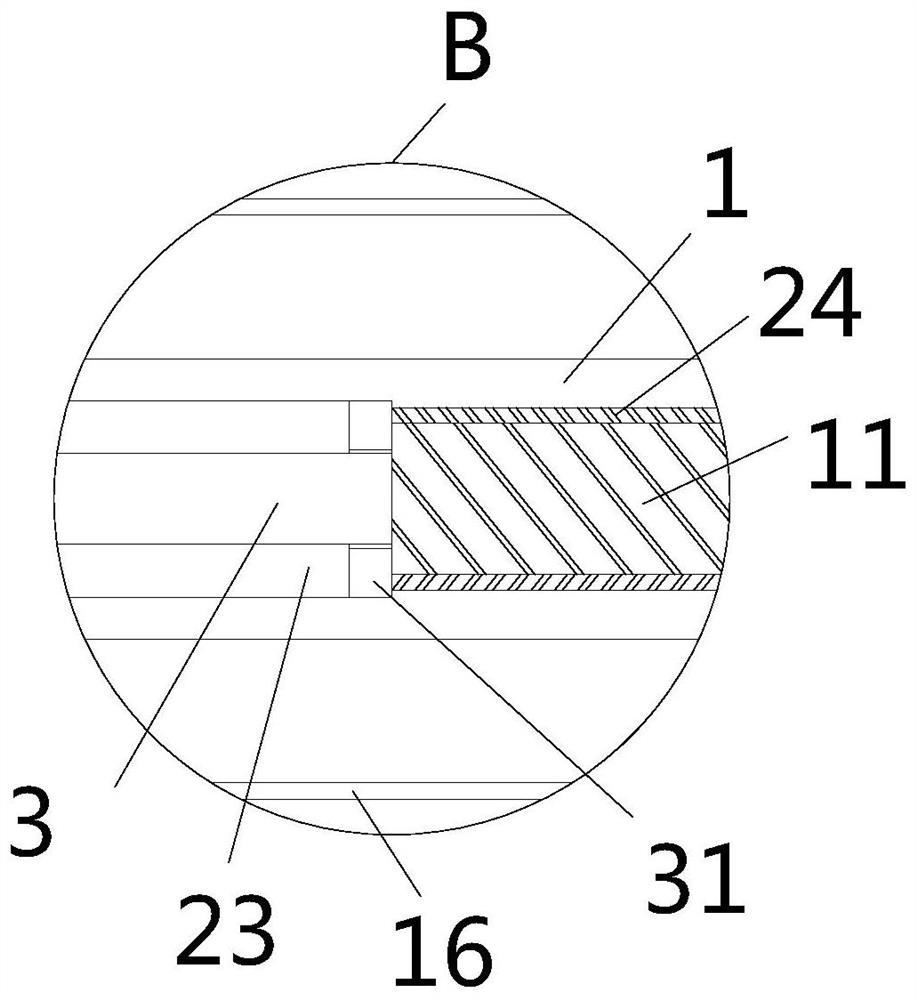

[0029] See Figure 1-6The present invention provides a technical solution: a fruit picking machinery, including pick rod 1, pick rod 1 is a cylinder, picking rod 1 Right end wall screw connection with threaded rod 11, threaded rod 11 Right end fixed connection The cover 12, the hose 12 is the hollow sphere of the right side, and the slider 13 having a ring array distribution is provided on the hollow wall surface of the picking cover 12, the slider 13 is curved, and the hip cover 12 wall surface is opened. The limit slot 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com