Pickling device for pickled food processing

A technology for pickling food and a bottom cylinder is applied in the field of pickling devices for processing pickled foods, which can solve the problems of long pickling time, lack of cleaning mechanism, and inability to handle pickling in time, so as to avoid the interference of external bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

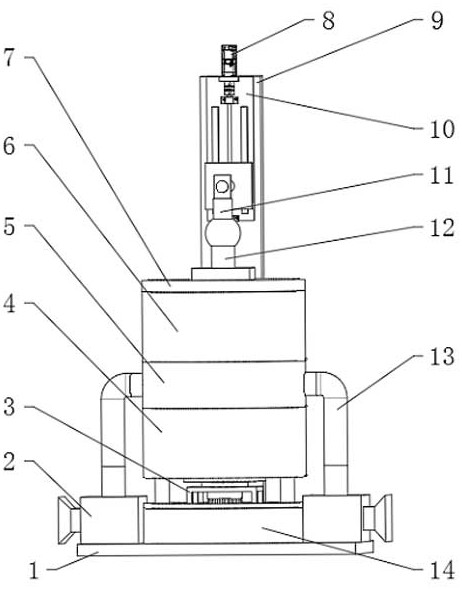

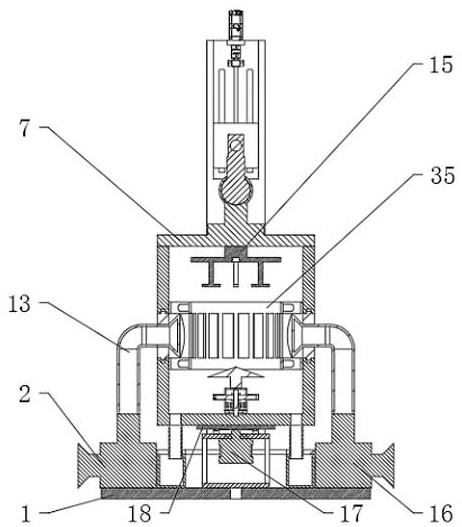

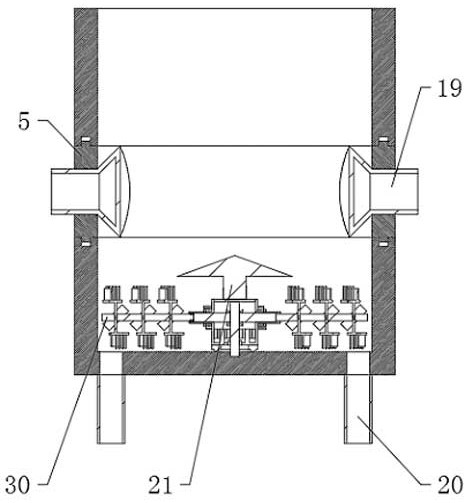

[0034]A pickling device for pickling food processing, such as Figure 1-5 As shown, it includes a bottom plate 1, the top outer wall of the bottom plate 1 is fixedly connected with a frame 3, the top outer wall of the frame 3 is fixedly connected with a fixed sleeve, the top outer wall of the fixed sleeve is slidably connected with a turntable 18, and the top outer wall of the turntable 18 is fixedly connected with a bottom cylinder 4, The inner wall of the bottom of the bottom cylinder 4 is fixedly connected with a rotary assembly, and the outer wall of the rotary assembly is fixedly connected with a wiper assembly 30; The bottom outer wall of the rotary cylinder 24 is fixedly connected with a sliding frame 23, the bottom outer wall of the sliding frame 23 is slidably connected to the bottom inner wall of the bottom cylinder 4, and the bottom inner wall of the bottom cylinder 4 is provided with four evenly arranged fixed columns. The outer gear 29 is fixedly connected to the ...

Embodiment 2

[0037] In order to optimize the process of food pickling and improve the quality; such as figure 1 , 2 , 3, 6, and 7, the outer wall of the top of the bottom cylinder 4 is rotatably connected with a middle cylinder 5, the top and bottom outer walls of the middle cylinder 5 are provided with tracks, and the outer wall of the top of the middle cylinder 5 is rotatably connected with an upper cylinder 6, and the upper cylinder 6 Both the outer wall of the bottom and the outer wall of the top of the bottom cylinder 4 are provided with a chute, and the outer wall of the track is slidably connected to the inner wall of the chute; the inner wall of the middle cylinder 5 is provided with two symmetrically arranged installation holes, and the inner wall of the installation hole is fixedly connected with a pipe joint 19, and the pipe joint 19 is fixed on the inner wall of the installation hole. The outer wall of one end of the joint 19 is provided with arc milling, and the outer wall of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap