Multi-stage cyclone desanding device

A cyclone desanding and cyclone technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of filter clogging, bulky volume, complicated operation, etc., and achieve improved gas production and sand discharge Good effect and high precision of sand removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

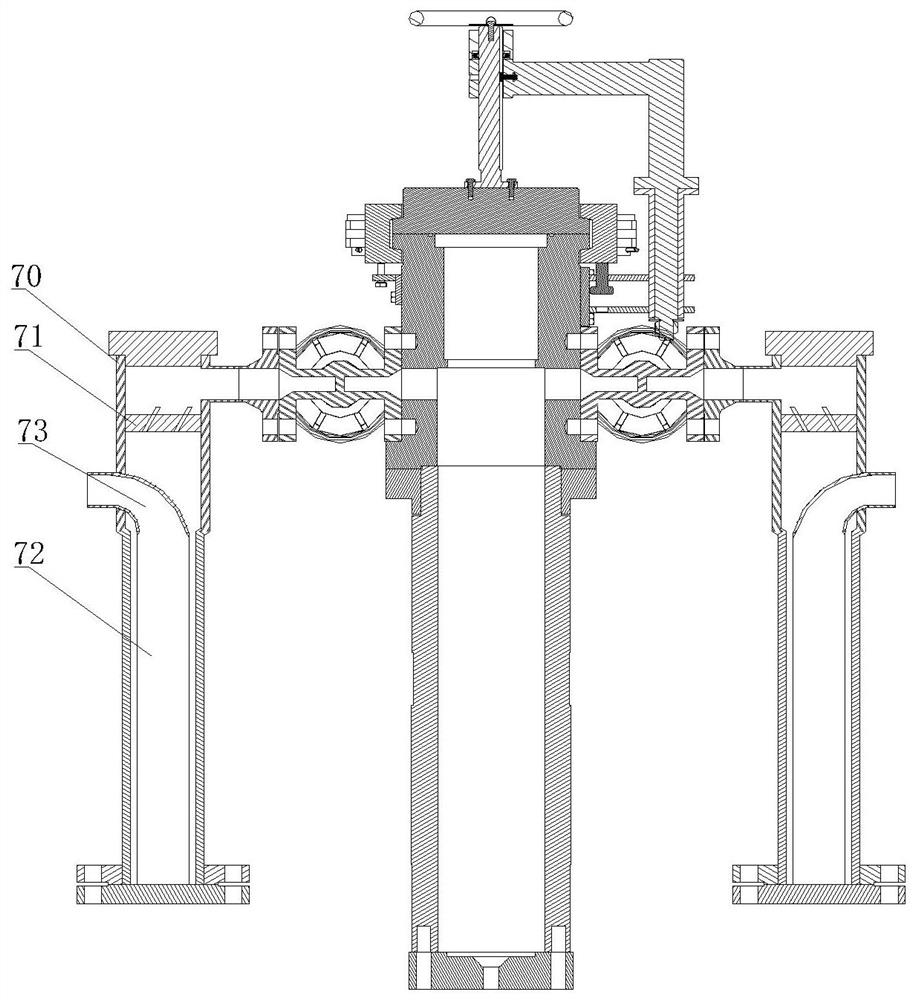

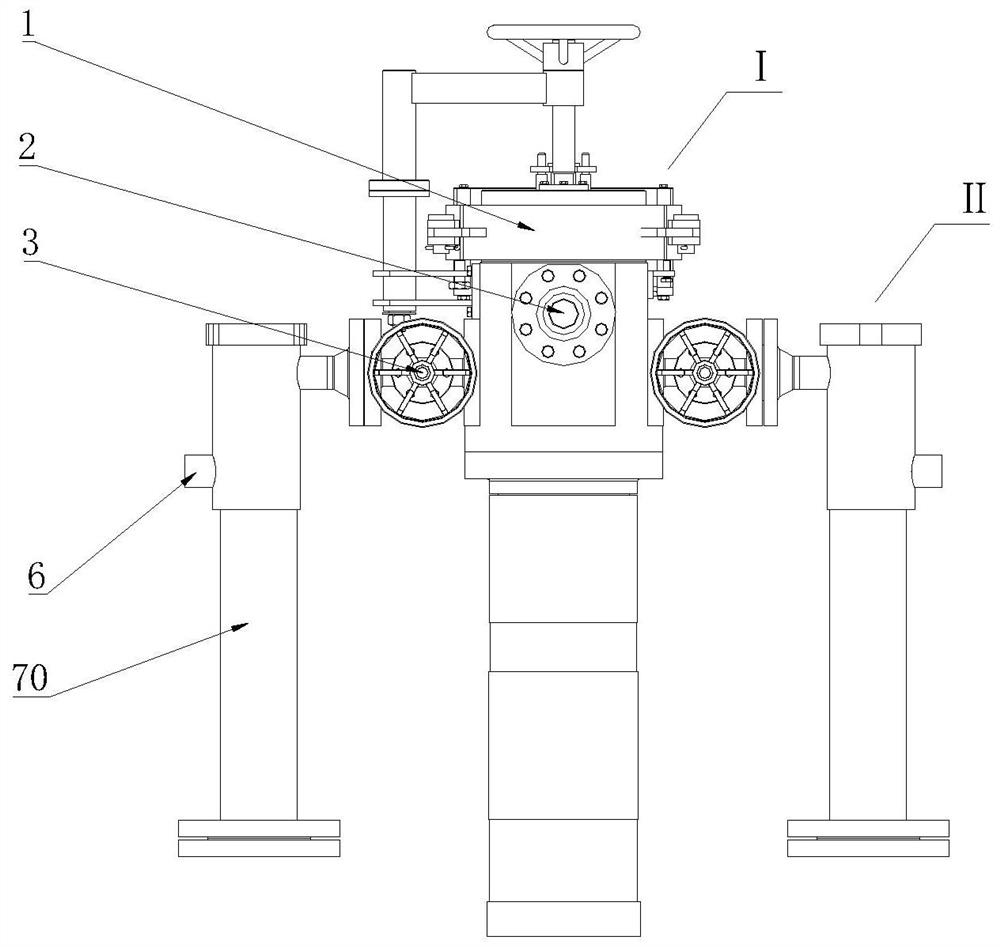

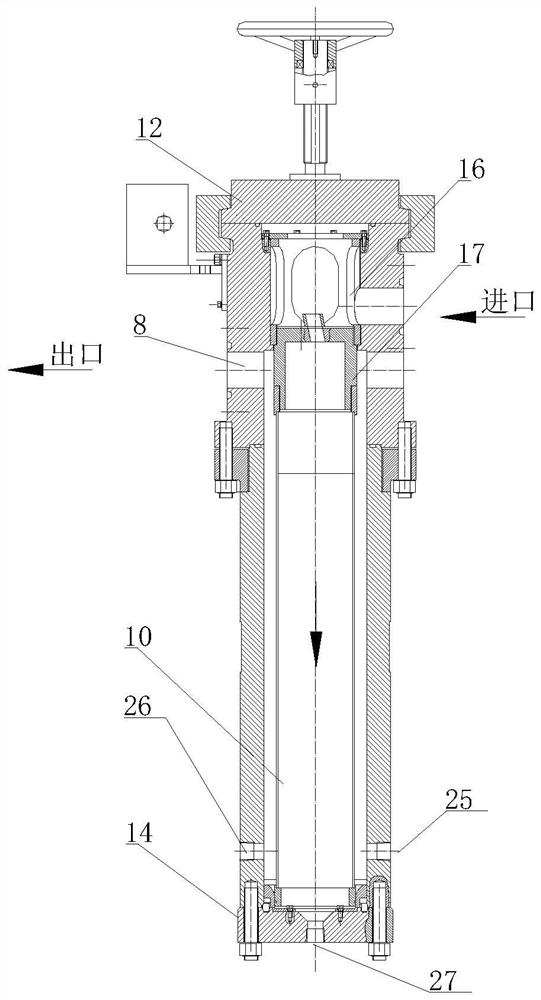

[0018] a kind of like Figure 1-Figure 3 The multi-stage cyclone sand removal device shown includes a first-stage sand removal system I, at least two or more in number, and a second-stage sand removal system II that is arranged on the side of the first-stage sand removal system I and communicated with it. In this embodiment, a multi-stage cyclone desanding device formed by connecting the first-stage sand removal system I and two second-stage sand removal systems II is described in detail. In the actual application process, three or four or more second-stage Sand removal system II, its connection layout is similar to the multi-stage cyclone sand removal device formed by the connection of primary sand removal system I and two secondary sand removal systems II, and will not be exhaustive here.

[0019] Specifically, the primary sand removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com