Die for stamping bottom plate of forehead thermometer

A technology of forehead temperature gun and base plate, which is applied in the field of stamping dies, can solve the problems of not being able to meet the large-scale production of dies, increase the cost of die maintenance, and the die punches are easy to break, so as to reduce maintenance costs, improve service life and meet production needs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

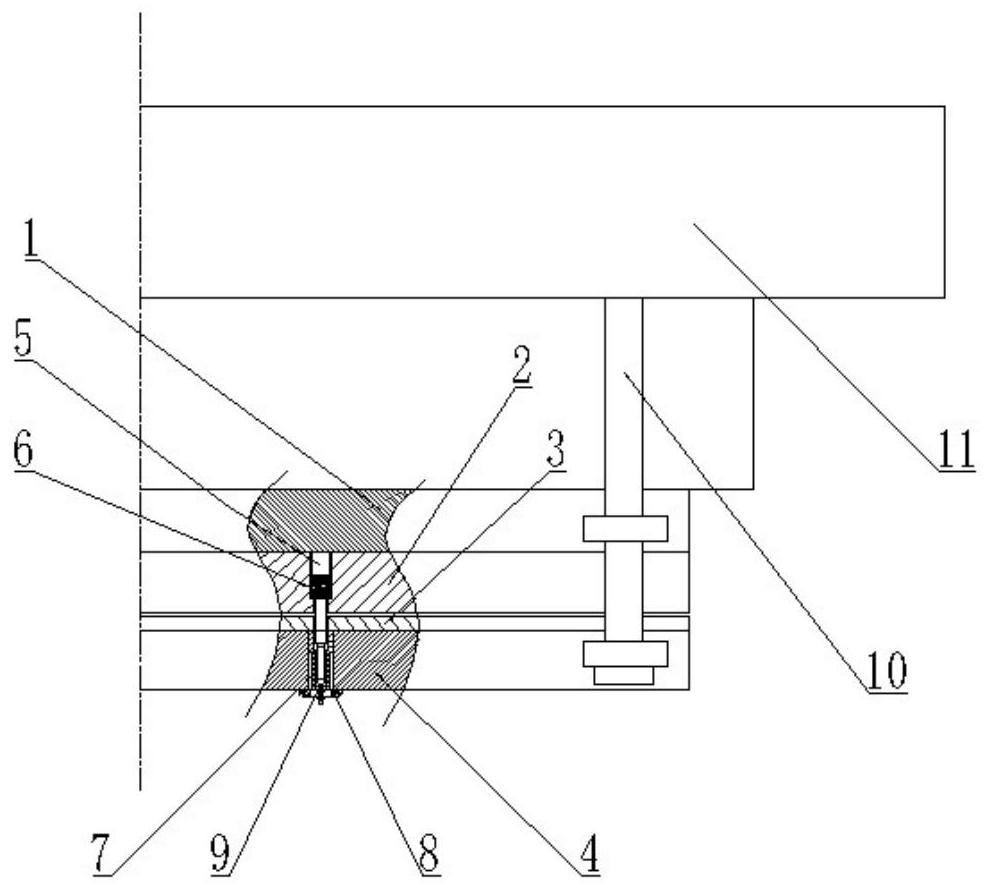

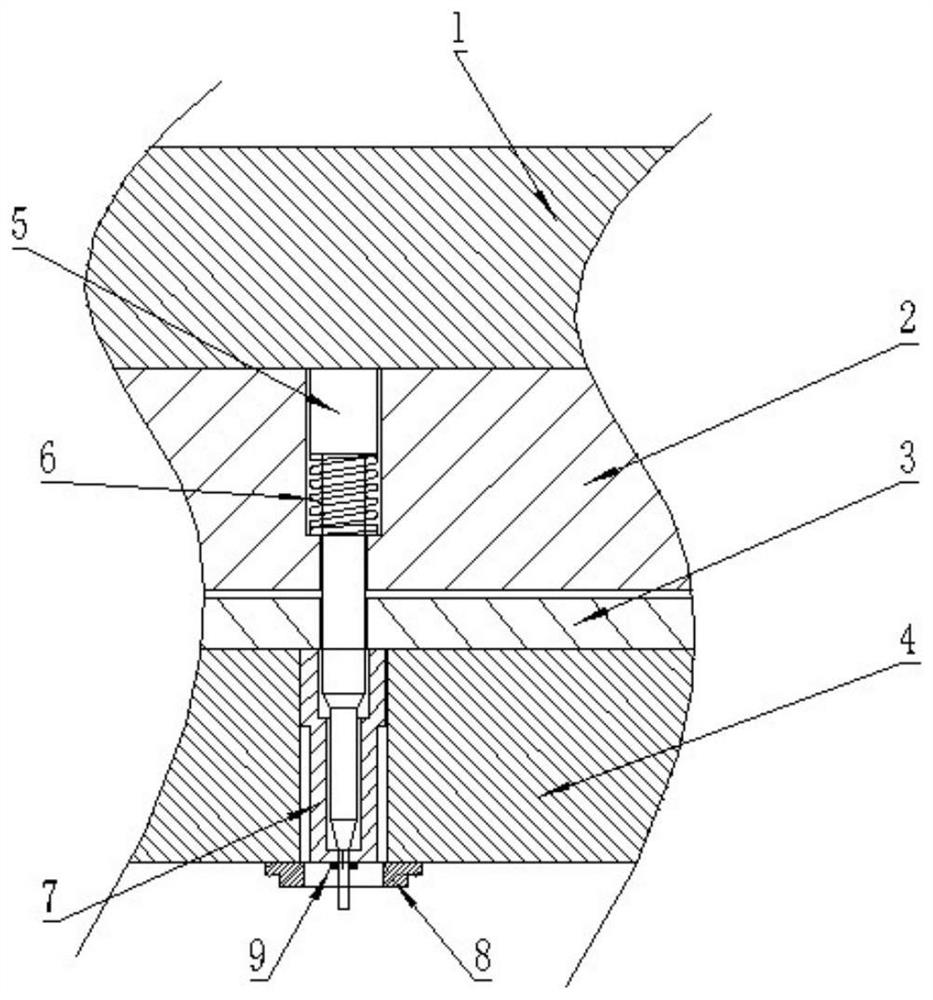

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

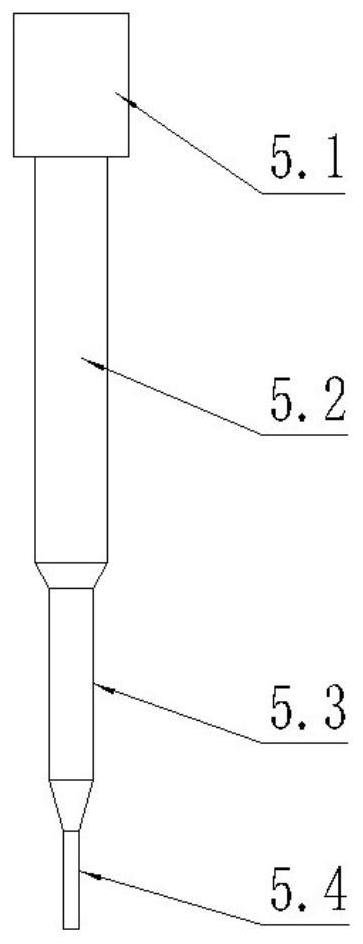

[0026] A kind of upper die (referring to Figure 1-4 ), including the upper die base 11, the upper backing plate 1 is fixedly installed on the upper die base 11, and the splint 2 is fixedly installed on the upper backing plate 1; a plurality of step-shaped punch mounting holes are evenly arranged on the splint 2, and the punch 5 is inserted into the punch installation hole, and a buffer spring 6 is arranged in the punch installation hole, and the buffer spring 6 is set on the punch 5; A plurality of punch installation holes A, a plurality of punch installation holes B are evenly arranged on the binder plate 4; the adjustment backing plate 3 is located between the splint 2 and the binder plate 4; the punch installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com