A kind of axial chiral anilide compound and its preparation method and application

An axial chirality and anilide technology, applied in the field of compound synthesis, can solve problems such as difficulty in generalization, and achieve the effect of high enantioselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

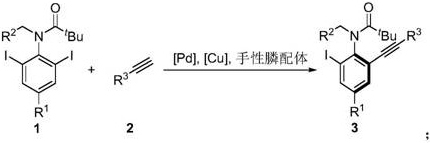

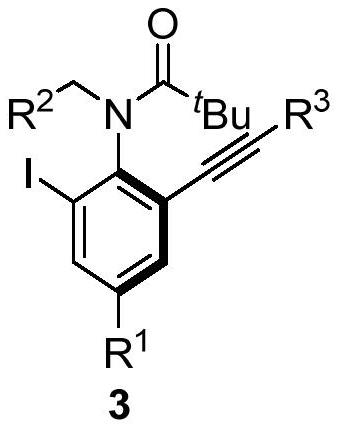

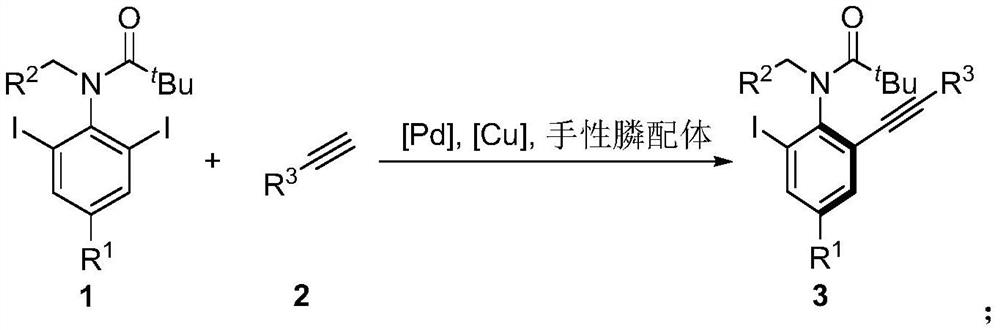

Method used

Image

Examples

Embodiment 1

[0044]

[0045] The specific operation is: under the protection of nitrogen, add Pd(OAc) to the dry Shrek tube 2 (0.02mmol), organophosphine ligand L19 (0.04mmol) and 2ml of anhydrous ethyl acetate, stirred at room temperature for 1h. Then CuI (0.01 mmol), substrate 1a (0.2 mmol), substrate 2a (0.4 mmol) and cesium acetate (0.4 mmol) were added, and stirred at 5° C. for 60 h. The reaction solution was concentrated, and 95.0 mg of product 3aa was obtained by column chromatography, with a yield of 81%, and 97% ee by HPLC.

[0046] Product characterization data are:

[0047] 1H NMR (400MHz, CDCl 3 )δ=7.74(d,J=1.3,1H),7.65–7.59(m,6H),7.48(t,J=7.5,2H),7.44(d,J=1.2,1H),7.39(t,J =7.3,1H),4.05(dd,J=13.6,7.8,1H),2.99(dd,J=13.6,5.2,1H),2.37(s,3H),2.08(d,J=12.2,1H), 1.85–1.73(m,1H),1.68–1.60(m,2H),1.60–1.50(m,2H),1.16(s,9H),1.14–1.05(m,3H),1.04–0.89(m,2H ). 13 C NMR (101MHz, CDCl 3 )δ178.17,145.76,141.56,140.86,140.18,139.11,133.83,132.09,128.91,127.79,127.12,127.05,125.49,121...

Embodiment 2

[0050]

[0051] The specific operation is: under the protection of nitrogen, add Pd(OAc) to the dry Shrek tube 2 (0.02mmol), organophosphine ligand L19 (0.04mmol) and 2ml of anhydrous ethyl acetate, stirred at room temperature for 1h. Then CuI (0.01 mmol), substrate 1a (0.2 mmol), substrate 2b (0.4 mmol) and cesium acetate (0.4 mmol) were added, and stirred at 5° C. for 60 h. The reaction solution was concentrated, and 84.2 mg of product 3ab was obtained by column chromatography, with a yield of 82%, and 96% ee by HPLC.

[0052] Product characterization data are:

[0053] 1 H NMR (400MHz, CDCl 3 )δ7.73(d,J=1.3Hz,1H),7.55–7.50(m,2H),7.42(d,J=1.2Hz,1H),7.38–7.32(m,3H),4.03(dd,J =13.6,7.9Hz,1H),2.96(dd,J=13.6,5.2Hz,1H),2.36(s,3H),2.04(d,J=12.5Hz,1H),1.85–1.69(m,1H) ,1.67–1.57(m,2H),1.55–1.47(m,2H),1.14(s,9H),1.11–1.02(m,3H),1.02–0.85(m,2H). 13 C NMR (101MHz, CDCl 3 )δ178.11,145.76,140.85,139.09,133.85,131.65,128.86,128.45,125.45,122.40,102.69,94.54,87.25,59.87,41.97,37....

Embodiment 3

[0055]

[0056] The specific operation is: under the protection of nitrogen, add Pd(OAc) to the dry Shrek tube 2 (0.02mmol), organophosphine ligand L19 (0.04mmol) and 2ml of anhydrous ethyl acetate, stirred at room temperature for 1h. Then CuI (0.01 mmol), substrate 1a (0.2 mmol), substrate 2c (0.4 mmol) and cesium acetate (0.4 mmol) were added, and stirred at 5° C. for 60 h. The reaction solution was concentrated, and 86.5 mg of product 3ac was obtained by column chromatography, with a yield of 82%, and 96% ee by HPLC.

[0057] Product characterization data are:

[0058] 1 H NMR (400MHz, CDCl 3 )δ7.69(s,1H),7.42–7.33(m,3H),7.14(d,J=7.9Hz,2H),4.01(dd,J=13.6,7.9Hz,1H),2.92(dd,J =13.6,5.1Hz,1H),2.36(s,3H),2.33(s,3H),2.02(d,J=12.4Hz,1H),1.79–1.68(m,1H),1.66–1.56(m, 2H),1.54–1.45(m,2H),1.11(s,9H),1.09–1.00(m,3H),0.98–0.82(m,2H). 13 C NMR (101MHz, CDCl 3 )δ177.99,145.49,140.48,138.99,138.90,133.62,131.43,129.09,125.54,119.21,102.52,94.72,86.56,59.73,41.83,37.35,32.12,29.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com