Method for repairing insulating end plate at glued insulating joint

A technology of insulating joints and insulating end plates, which is applied to the joints of rails, roads, tracks, etc., can solve the problems of time-consuming, labor-intensive and costly bonding of insulating joint devices, and damage of insulating end plates, so as to shorten the time of repair work and ensure good quality. Adhesiveness, the effect of saving material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

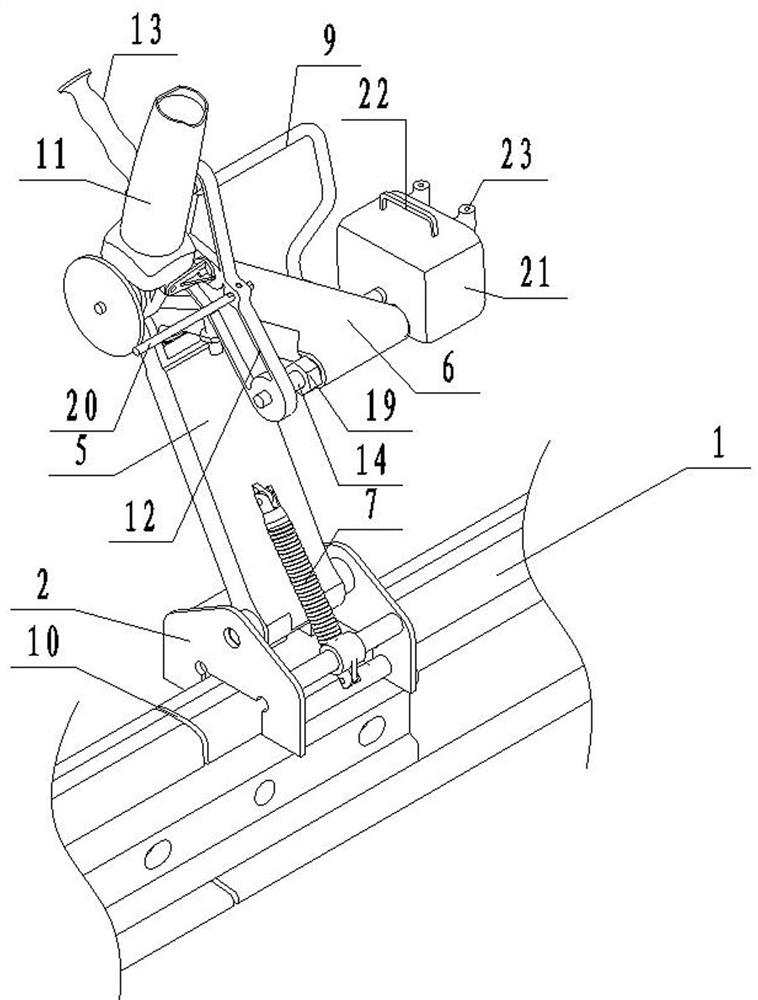

[0030] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0031] An embodiment of the present invention provides a method for repairing an insulating end plate 10 at a glued insulating joint, comprising the following steps:

[0032] 1) Locate the glued insulating joint on rail 1 that needs to be repaired.

[0033] 2) Fix the repair device on the rail 1 on the side of the glued insulating joint;

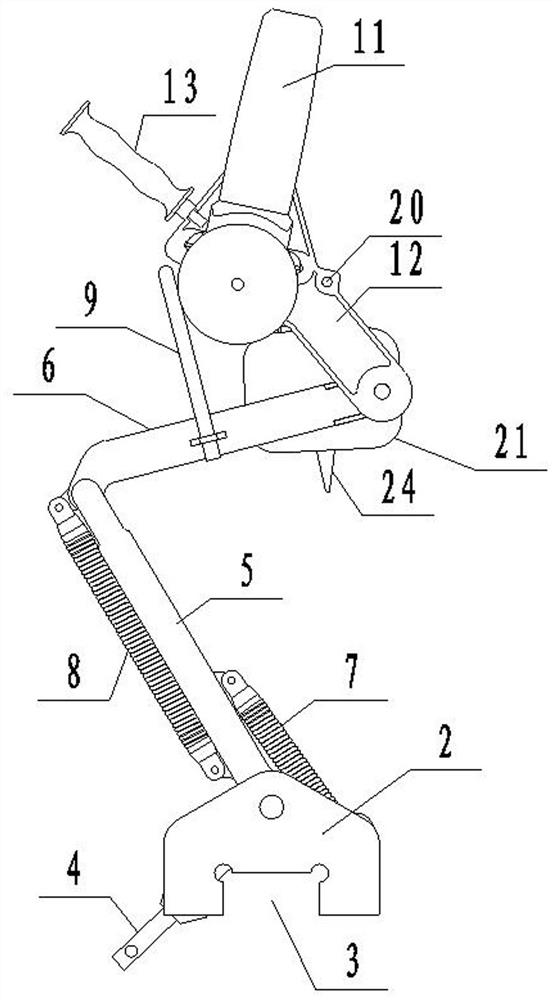

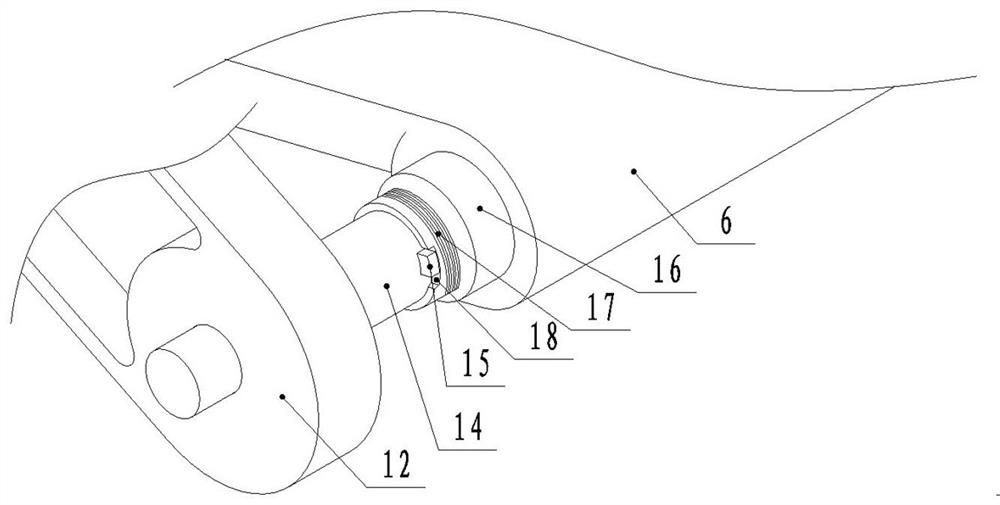

[0034] Such as figure 1As shown, the repair device includes a base 2, a bracket, a cutting part and a glue injection part; the bottom end of the base 2 is provided with a slot 3 for clamping the rail 1, and a fas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com