Construction method and structure of four-direction unbonded prestressed crossed beam-column joint

A beam-column joint and construction method technology, applied in structural elements, building structures, building components, etc., can solve the problems of long construction period, high construction difficulty, poor safety of component connection nodes, etc. The effect of improving the strength of column-beam joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A four-direction unbonded prestressed cross-beam-column joint construction method, the construction process includes:

[0035] (1) Hoisting construction of assembly structural columns. In order to better cooperate with the accurate piercing operation of the superimposed T-beam under the slab and the protruding unbonded prestressed tendons, before hoisting the assembly structure column, the elevation of the bottom position of the composite beam should be marked on the corresponding side of the assembly structure column with a "spring line" Well, during the hoisting process of each assembled structural column, use four-sided inclined adjustable steel supports, and ensure that the assembled structural column grouting material cannot be removed before it is completely solidified.

[0036] (2) The vertical two superimposed T-beams under the slab are hoisted in place, and the outstretched non-bonded prestressed tendons are cross-punctured. After the hoisting of the assembled...

Embodiment 2

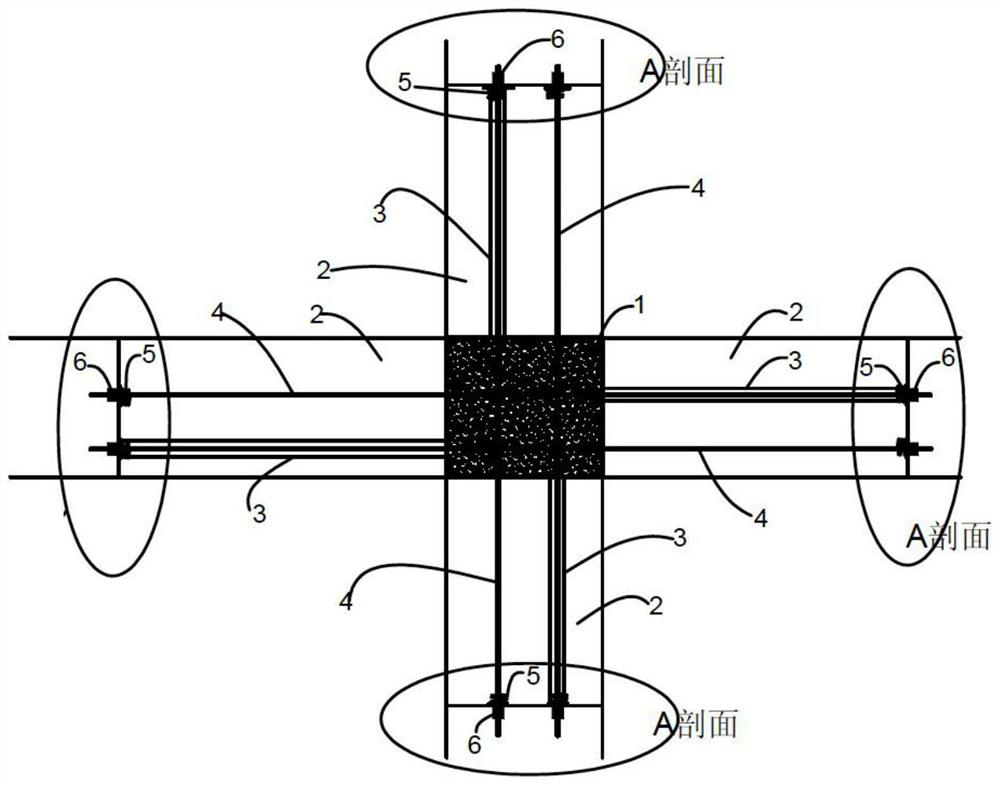

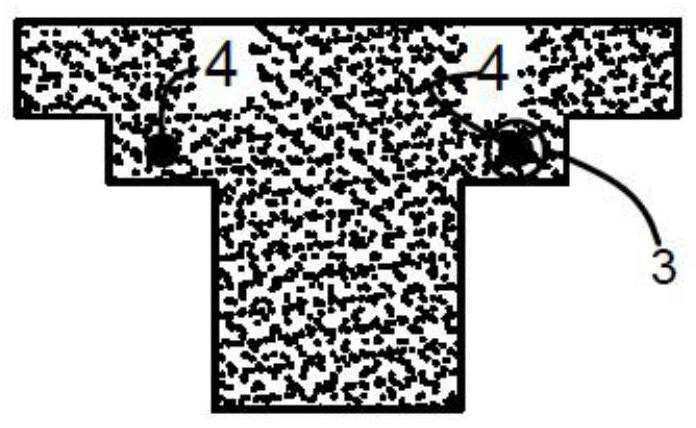

[0044] On the basis of the implementation of Example 1, a four-direction unbonded prestressed cross-beam-column joint structure, such as figure 1 , 2 As shown, it includes prefabricated column 1, laminated T beam under the slab 2, prestressed tunnel 3, unbonded prestressed steel bar 4, pressure plate with spiral reinforcement 5, and anchorage 6; the laminated T beam under the slab 2 vertically crosses It is arranged around the top of the prefabricated column 1 , that is, the top of the prefabricated column 1 is vertically provided with under-slab laminated T beams 2 in four directions. The T-shaped section of the laminated T-beam 2 under the slab is only partially set, and the T-shaped section of the laminated T-beam 2 under the slab is attached to the prefabricated column 1; The end of the T-shaped section of the lower superimposed T-beam 2 is pre-embedded with a spiral reinforcement pressure plate 5; the unbonded prestressed steel bars 4 pass through the prestressed tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com