Single-pipe tower reinforcing device and method

A reinforcement device and single-pipe tower technology, which is applied to towers, building maintenance, building types, etc., can solve problems such as unsatisfactory requirements and large site requirements, and achieve the effects of wide application range, reduced site requirements, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

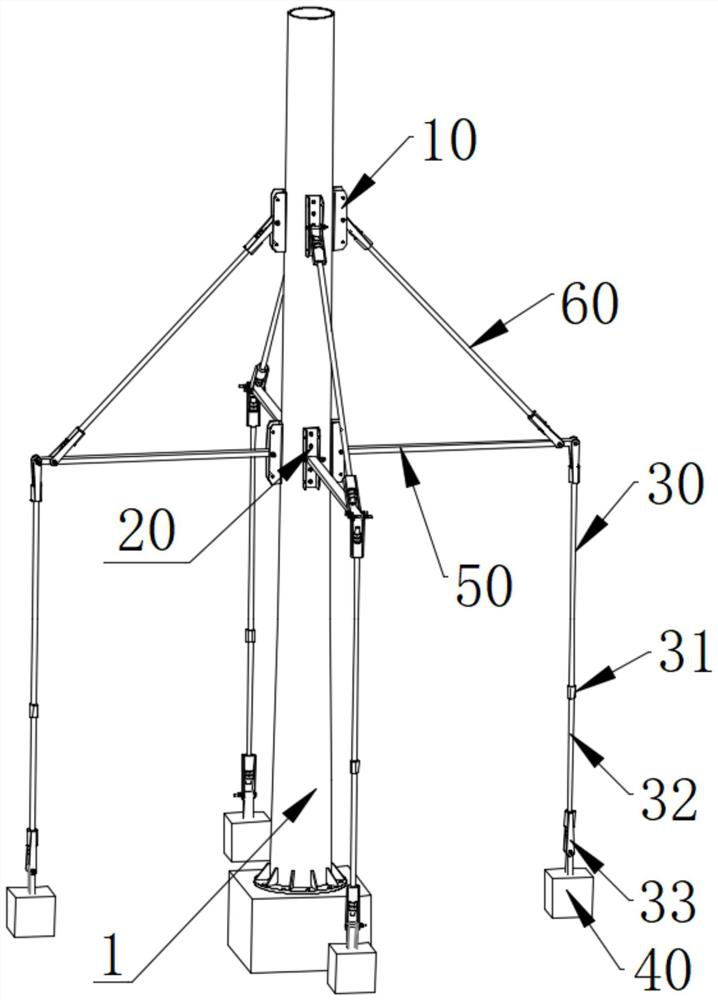

[0032] refer to figure 1 , this embodiment provides a reinforcement device for a single-pipe tower, including a single-pipe tower 1, the single-pipe tower 1 is fixed on the counterweight at the bottom, and the outer surface of the single-pipe tower 1 is sequentially from top to bottom The first reinforcement device 10 and the second reinforcement device 20 are installed, and the first reinforcement device 10 and the second reinforcement device 20 all include a plurality of reinforcement blocks fixed on the surface of the single tube tower 1, and the second reinforcement device 20 A support block 50 is fixed on the reinforcement block, and the outer end of the support block 50 is connected to the reinforcement block of the first reinforcement device 10 at the same vertical position to form a triangular structure through the first tensioning device 60, and the support The block 50 is arranged horizontally; the outer end of the support block 50 is connected with the foundation co...

Embodiment 2

[0042] This embodiment provides a reinforcement method for the reinforcement device of the single-pipe tower described in Embodiment 1, which includes the following steps:

[0043] (1) Prefabricate the components of the reinforcing device of the single-pipe tower and transport to the site;

[0044] (2) install the first reinforcement device 10 and the second reinforcement device 20 according to the preset height and distance;

[0045] (3) One end of the support block 50 is fixedly connected with the second reinforcing device 20;

[0046] (4) One end of the first tensioning device 60 is fixedly connected to the first reinforcement device 10, and the other end of the first tensioning device 60 is fixedly connected to the outer end of the support block 50 on the same vertical plane, forming a triangular structure , and make the support block 50 set horizontally;

[0047] (5) according to the length of support block 50, base counterweight block 40 is arranged on the periphery of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com