Electric supporting rod with overload protection function

An electric strut and overload protection technology, which is applied in the direction of automatic clutch, power control mechanism, wing leaf control mechanism, etc., can solve the problems of long fixed stroke of electric strut and difficulty of fixed stroke electric strut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

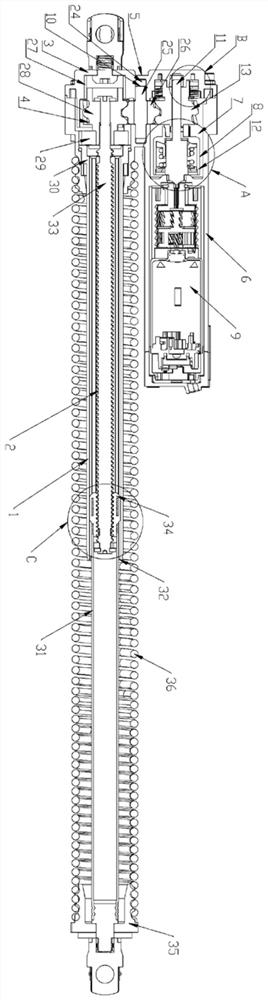

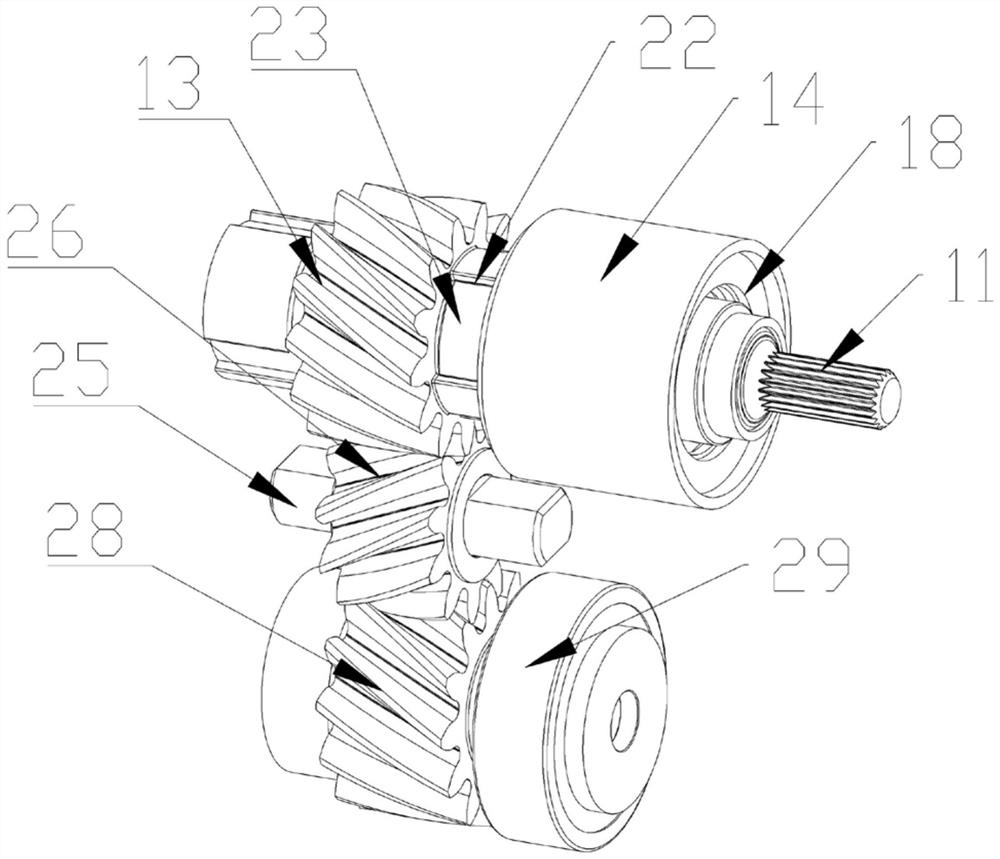

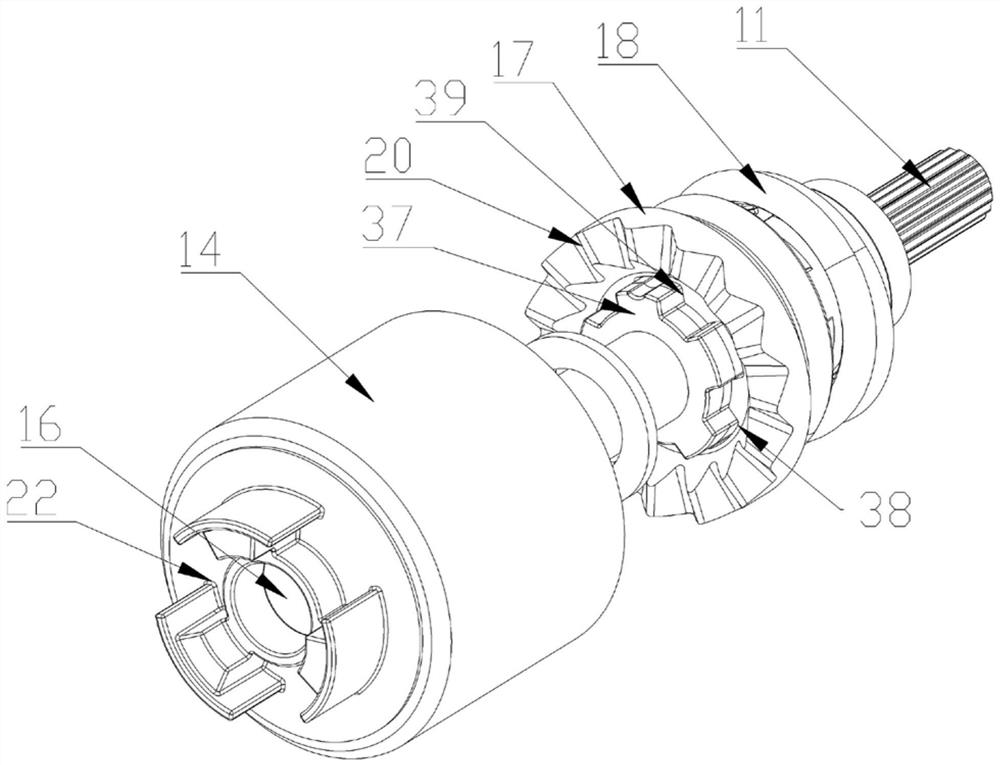

[0026] Embodiment 1: see Figure 1 to Figure 7: When the technical solution is in the no-overload state, the kinetic energy output by the motor after the motor in the second casing is energized and rotated will be output to the first rotating shaft through the reduction box provided by the motor, and because the first rotating shaft passes through the slider and the inner side wall of the separation disc The chute is slidingly connected, so the circumferential rotation of the first rotating shaft will drive the separation disc to perform circumferential rotation. At this time, the separation disc is inserted into the third housing through the first limit groove and the first limit protrusion near the end of the third housing, so the circumferential rotation of the separation disc will drive the third housing at the first position. Circumferential rotation is carried out in an accommodating cavity, so as to realize linkage output power to the casing. The side of the third hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com