Low-noise air blower

A blower, low-noise technology, applied in the field of blower, can solve the problems of negative impact of blower use, high noise, loud noise, etc., and achieve the effect of reducing vibration, noise and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

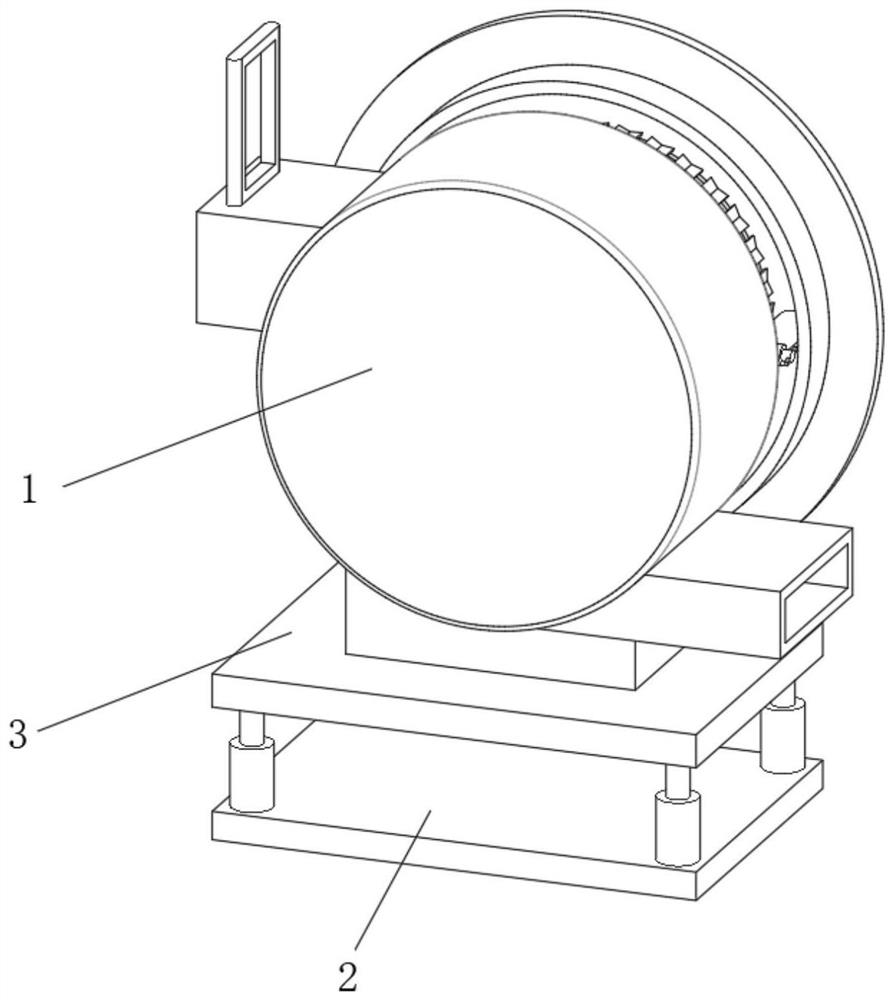

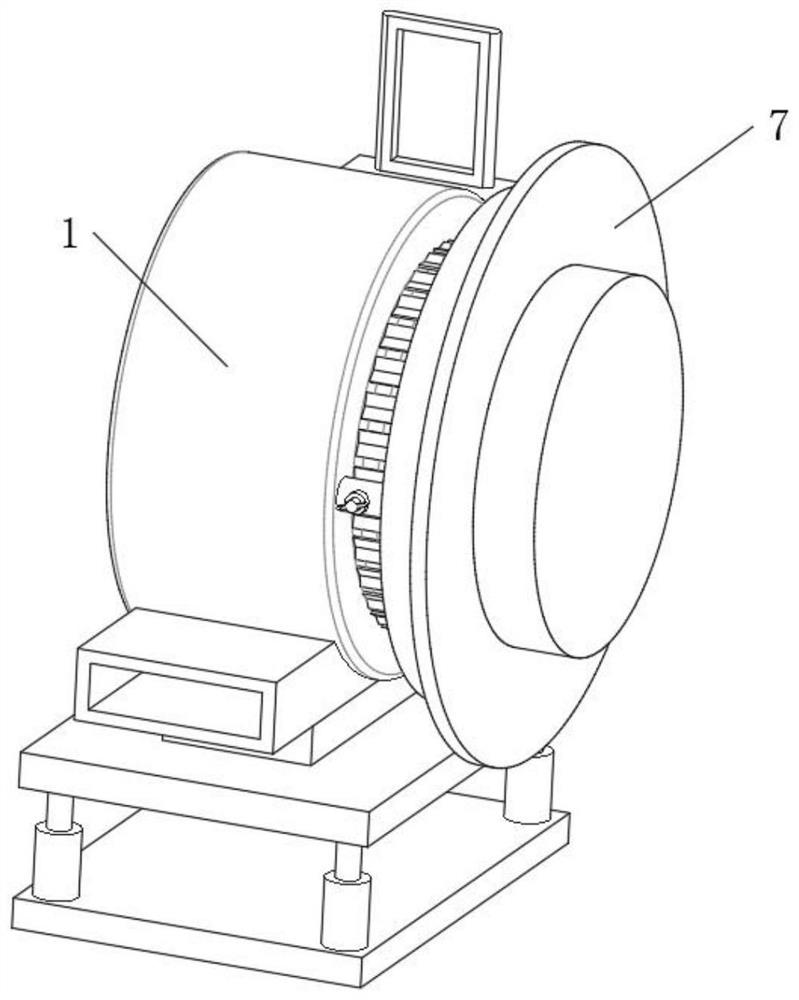

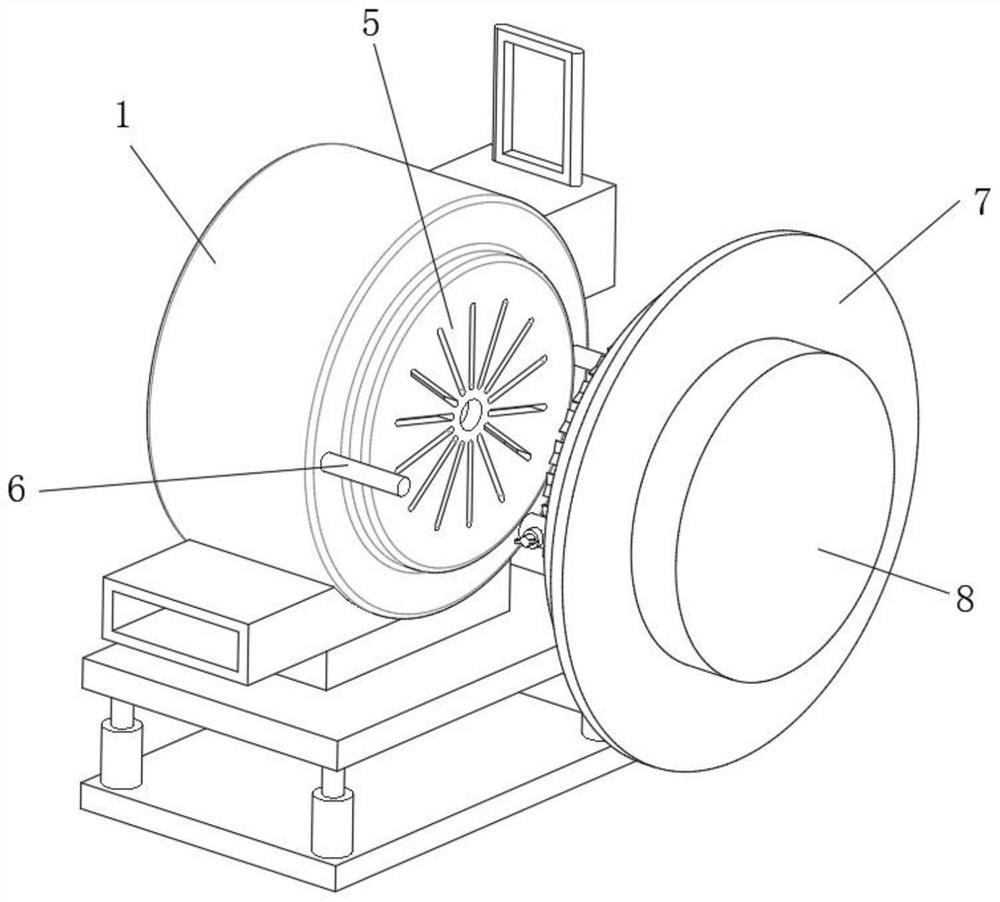

[0025] Embodiments of the present invention provide a low-noise blower, such as Figure 1-6 As shown, it includes the fan housing 1 and the bottom plate 2. The four corners of the top of the bottom plate 2 are fixedly connected with a buffer seat 201. The interior of the buffer seat 201 is provided with an inner cavity, and the inner cavity of the buffer seat 201 is provided with a buffer spring 202. The buffer spring The bottom of the buffer spring 202 is fixedly connected to the bottom wall of the inner cavity of the buffer seat 201, and the top of the buffer spring 202 is fixedly connected with a buffer rod 203, and the buffer rod 203 is slidably connected in the inner cavity of the buffer seat 201, and the top of the buffer rod 203 passes through the buffer The seat 201 extends upwards and is fixedly connected with the plane plate 3;

[0026] The noise reduction mechanism includes a sound insulation cover 7, the side wall of the sound insulation cover 7 is fixedly connecte...

Embodiment 2

[0030] Embodiments of the present invention provide a low-noise blower, such as Figure 1-6 As shown, it includes the fan housing 1 and the bottom plate 2. The four corners of the top of the bottom plate 2 are fixedly connected with a buffer seat 201. The interior of the buffer seat 201 is provided with an inner cavity, and the inner cavity of the buffer seat 201 is provided with a buffer spring 202. The buffer spring The bottom of the buffer spring 202 is fixedly connected to the bottom wall of the inner cavity of the buffer seat 201, and the top of the buffer spring 202 is fixedly connected with a buffer rod 203, and the buffer rod 203 is slidably connected in the inner cavity of the buffer seat 201, and the top of the buffer rod 203 passes through the buffer The seat 201 extends upwards and is fixedly connected with a flat plate 3, the top of the flat plate 3 is fixedly connected with a support platform 4, the bottom of the fan casing 1 is fixedly connected with the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com