Iron powder inner ring type stainless steel magnetic seal bearing

A magnetic bearing, stainless steel technology, applied in the direction of bearings, bearing components, shafts and bearings, can solve the problems of difficult assembly, inability to assemble, unsafe production movement, etc., to achieve the effect of easy installation and maintenance, and increased pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

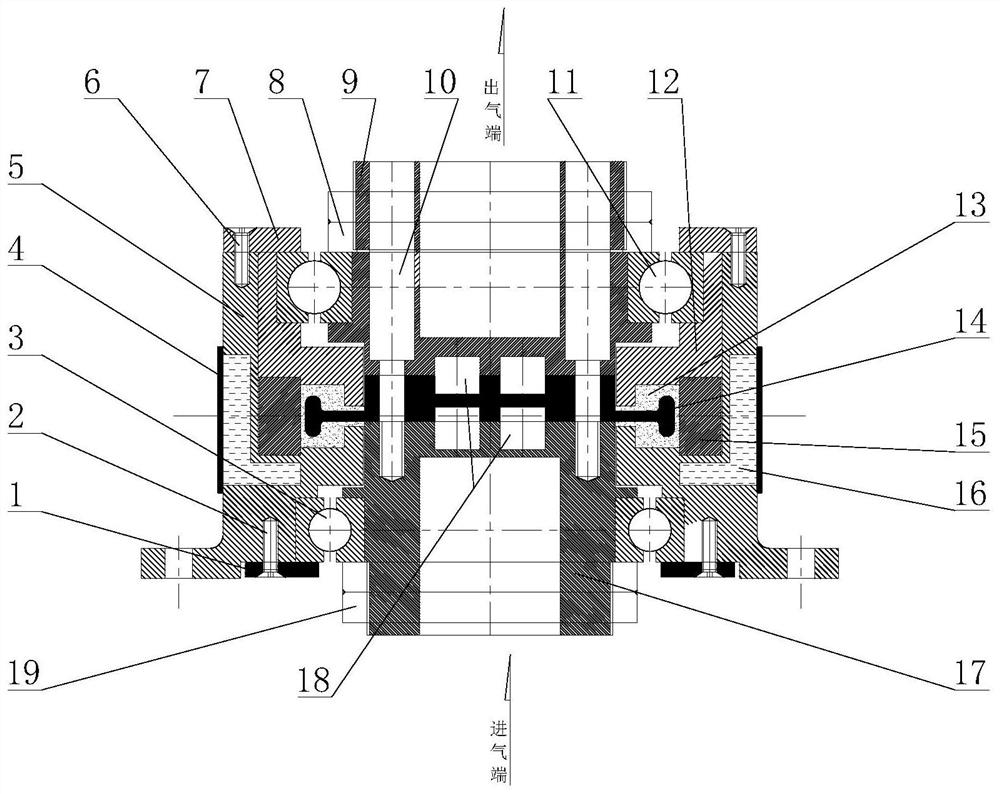

[0015] Such as figure 1 As shown, the present invention includes a magnetic bearing outer seat 5, the bottom of the magnetic bearing outer seat 5 is an air inlet end, and the top is an air outlet end, and also includes an upper power output shaft 9, a lower power shaft 17, and two symmetrical downward core bearings 3 , the upper radial bearing 11, the strong magnet 15, the air seal inner ring 14, two strong magnets 15 are symmetrically fixed in the magnetic bearing outer seat 5, and are pressed and fixed by the magnet pressing seat 12, the lower power shaft 17, the air seal inner ring The ring 14 and the upper power output shaft 9 are successively arranged in the outer seat 5 of the magnetic bearing from bottom to top, and are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com