Compact lip labyrinth shaft sealing unit, corresponding shaft seal and corresponding carrier roller

A shaft sealing, compact technology, applied in the direction of bearing components, shafts and bearings, rollers, etc., can solve the problems of small rotation resistance, large rotation resistance, and high allowable speed of labyrinth seals, and achieve good sealing effect, compact structure, The effect of high allowable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

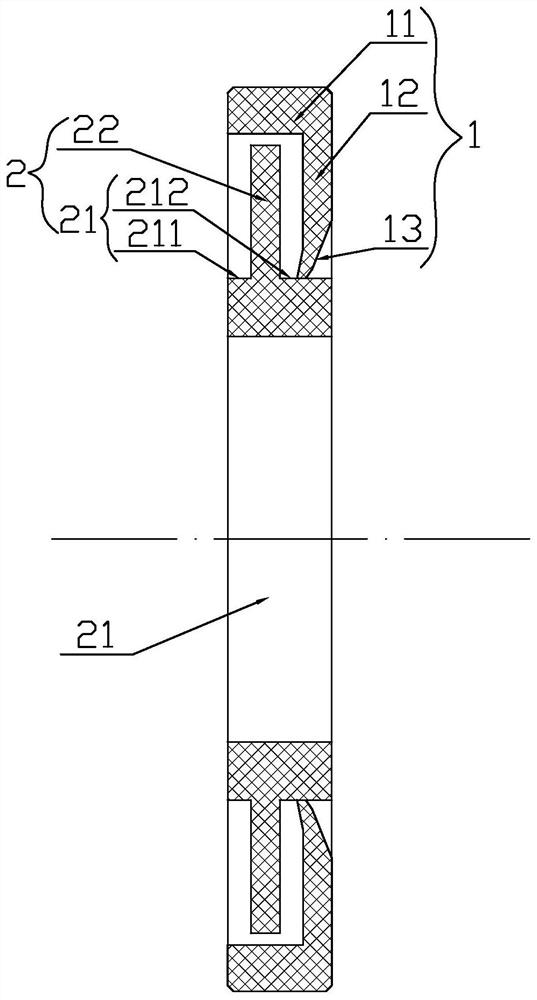

[0021] Implementation mode one: if figure 1 As shown, the compact lip labyrinth shaft seal unit includes an L-shaped outer seal ring 1, which is characterized in that it also includes a T-shaped inner seal ring 2, and the T-shaped inner seal ring 2 includes a shaft sleeve ring 21 and a spacer ring 22. The inner edge of the spacer ring 22 is fixedly connected to the outer circumference of the sleeve ring 21, and the two are integrally formed, and the spacer ring 22 divides the sleeve ring into an inner ring part 211 and an outer ring part 212. The T-shaped The shaft sleeve ring 21 of the inner sealing ring 2 is tightly fitted on the matching shaft ( figure 1 not shown, see Figure 2-4 ), the inner and outer end faces of the sleeve ring 21 of the T-shaped inner seal ring 2 are directly or indirectly clamped between the inner ring of the matching bearing and the spring retaining ring for the matching shaft, and are fixed on the matching shaft ( figure 1 not shown, see Figure ...

Embodiment approach 2

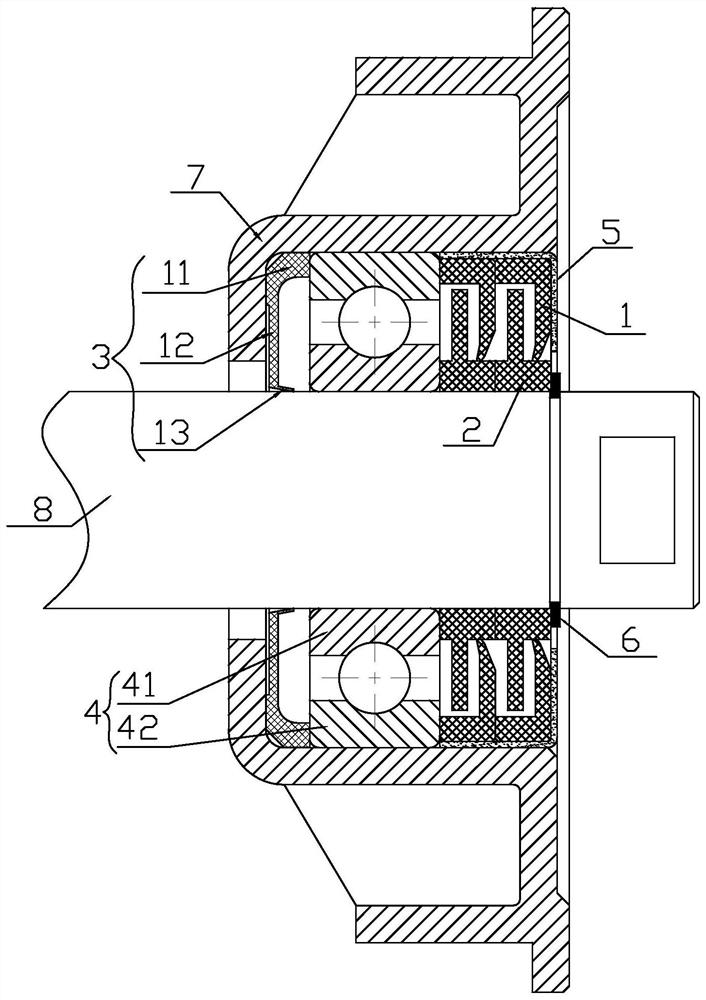

[0024] Implementation mode two: if figure 2 As shown, the shaft seal of the present invention includes a sealing ring 3, a bearing 4, an L-shaped retaining ring 5 and a spring retaining ring 6 for the shaft, and a matching bearing seat 7, a sealing ring 3, a bearing 4, an L-shaped retaining ring 5 and a shaft The retaining ring 6 is set on the matching shaft 8, the sealing ring 3, the bearing 4, the L-shaped retaining ring 5 and the spring retaining ring 6 for the shaft are all located in the matching bearing seat 7, and are arranged in sequence from the inside to the outside , is characterized in that: it also includes two sets of the aforementioned compact lip labyrinth shaft seal unit, the above-mentioned compact lip labyrinth shaft seal unit is sleeved side by side on the matching shaft 8 between the bearing 4 and the L-shaped retaining ring 5 Above, the lip ring 12 of each compact lip labyrinth shaft seal unit is located on the outer side of the spacer ring 22 of its mat...

Embodiment approach 3

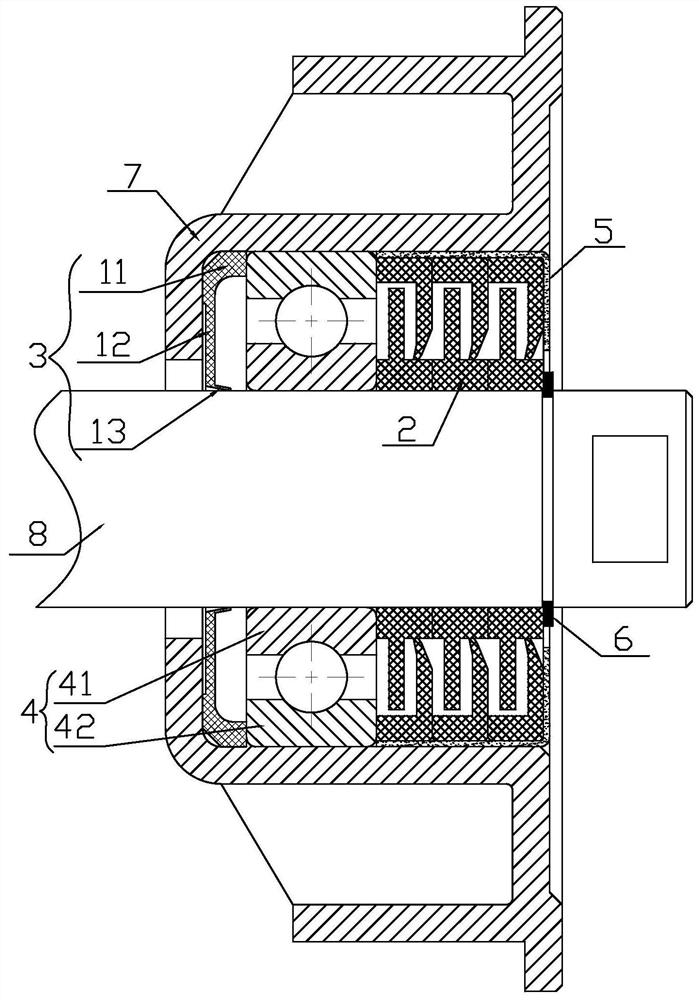

[0026] Implementation mode three: if image 3 As shown, the shaft seal of the present invention includes a sealing ring 3, a bearing 4, an L-shaped retaining ring 5 and a spring retaining ring 6 for the shaft, and a matching bearing seat 7, a sealing ring 3, a bearing 4, an L-shaped retaining ring 5 and a shaft The retaining ring 6 is set on the matching shaft 8, the sealing ring 3, the bearing 4, the L-shaped retaining ring 5 and the spring retaining ring 6 for the shaft are all located in the matching bearing seat 7, and are arranged in sequence from the inside to the outside , is characterized in that: it also includes three sets of the aforementioned compact lip labyrinth shaft sealing units, and the rest of the structure is as described in Embodiment 2, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com