Filter pressing testing device

A test device, hydraulic technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of affecting test results, low maximum pressure, and difficulty in taking out materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

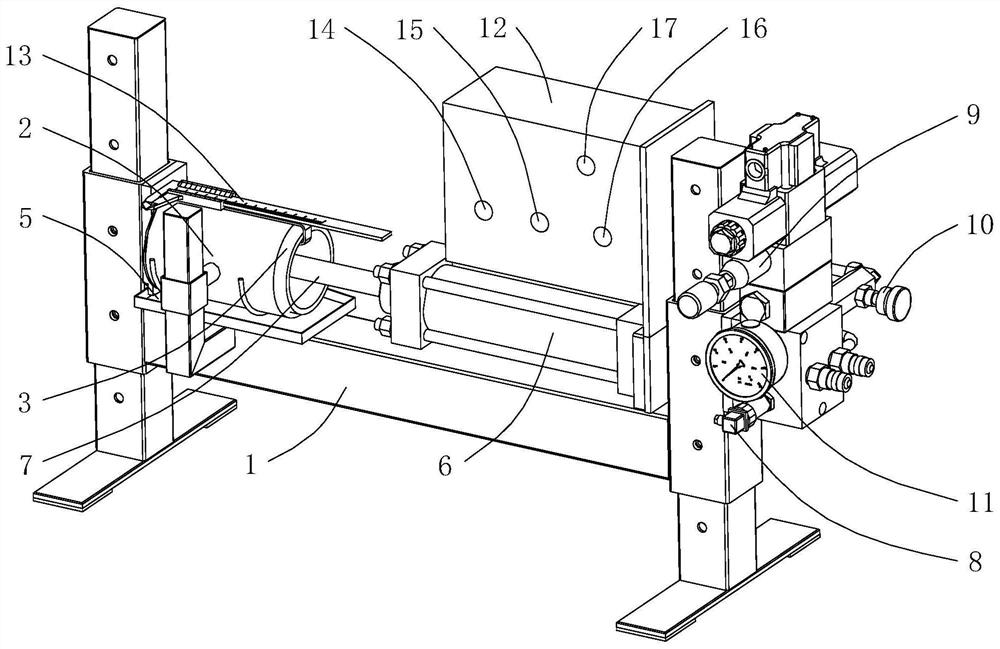

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

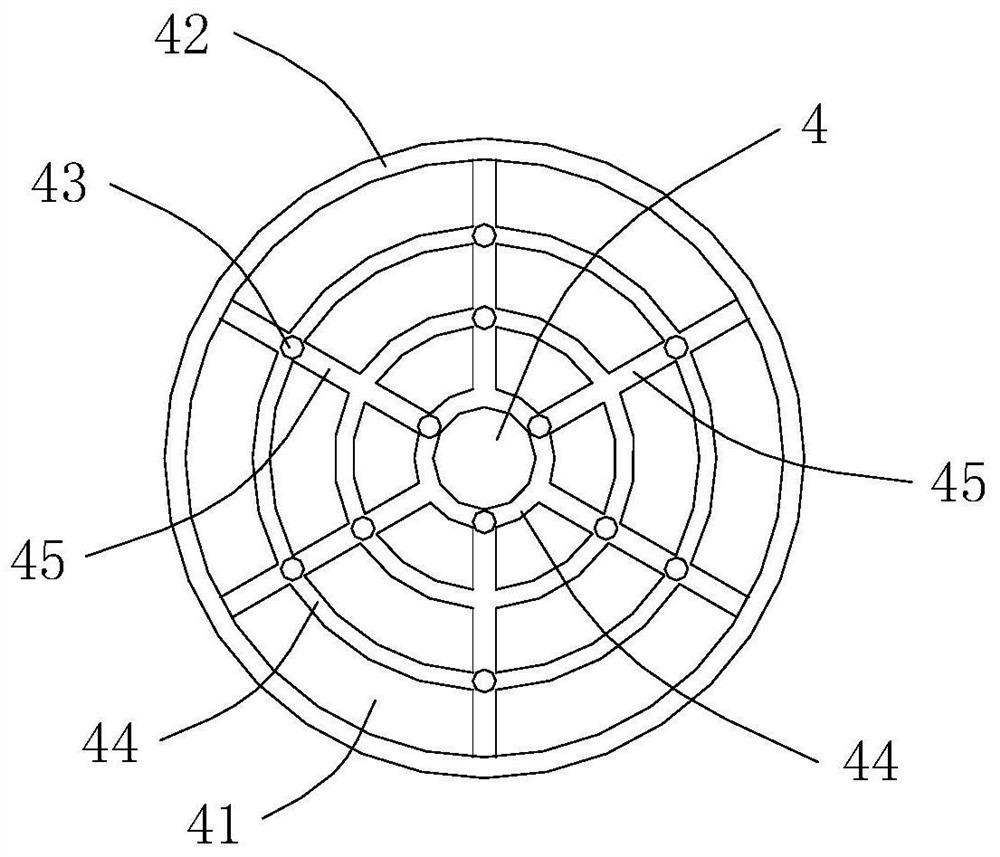

[0018] see Figure 1-2 As shown, the above-mentioned filter press test device includes a frame 1, an outer sleeve 2 fixed on the frame 1, a fixed ring against the first orifice plate at one end of the outer sleeve 2, and can be rotated along its own axis. The inner sleeve 3 in the outer sleeve 2 that can be plugged and inserted in the direction of the line, two second orifice plates 4 that can move along the axial direction of the inner sleeve 3 and ring against the inner sleeve 3, set The water tray 5 on the frame 1 and below the outer sleeve 2 .

[0019] see figure 1 As shown, in this embodiment, the outer sleeve 2 is fixedly connected with the frame 1 through its side and bottom. The first orifice plate is connected to the left end of the outer sleeve 2, and the two are integrally formed. The outer sleeve 2, the first orifice plate, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com