A battery pack housing assembly utilizing high-speed airflow for auxiliary heat dissipation

A technology of auxiliary heat dissipation and high-speed airflow, which is applied to battery pack parts, electrical components, secondary batteries, etc., can solve the problems of high temperature of the battery pack, insufficient power supply, and heat dissipation, so as to achieve sufficient and uniform heat dissipation, easy replacement, Guarantee the effect of stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

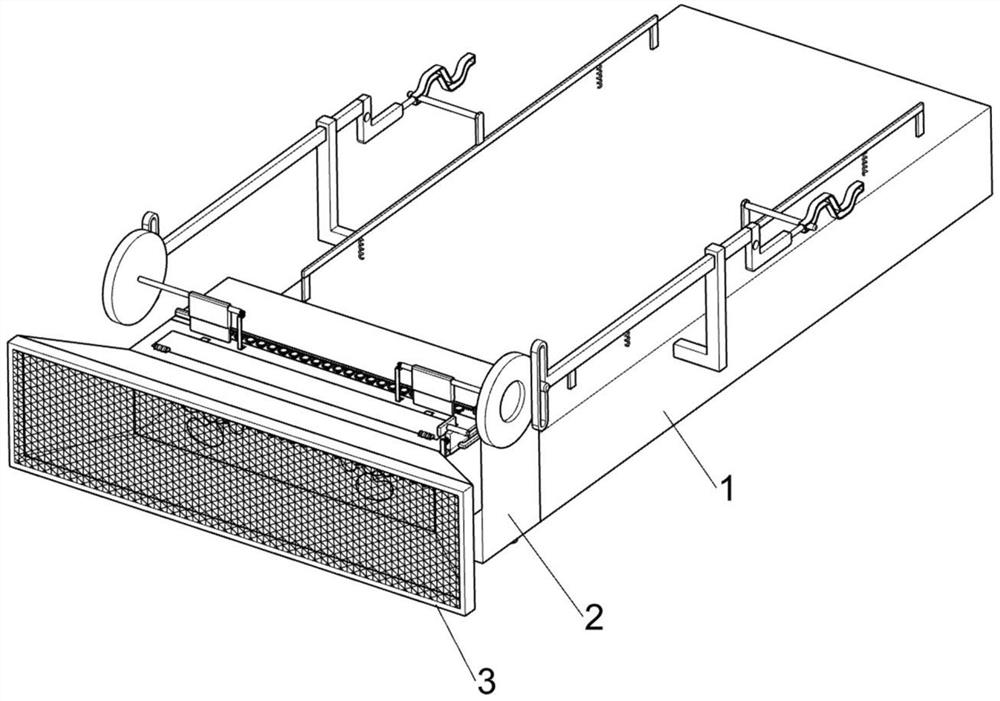

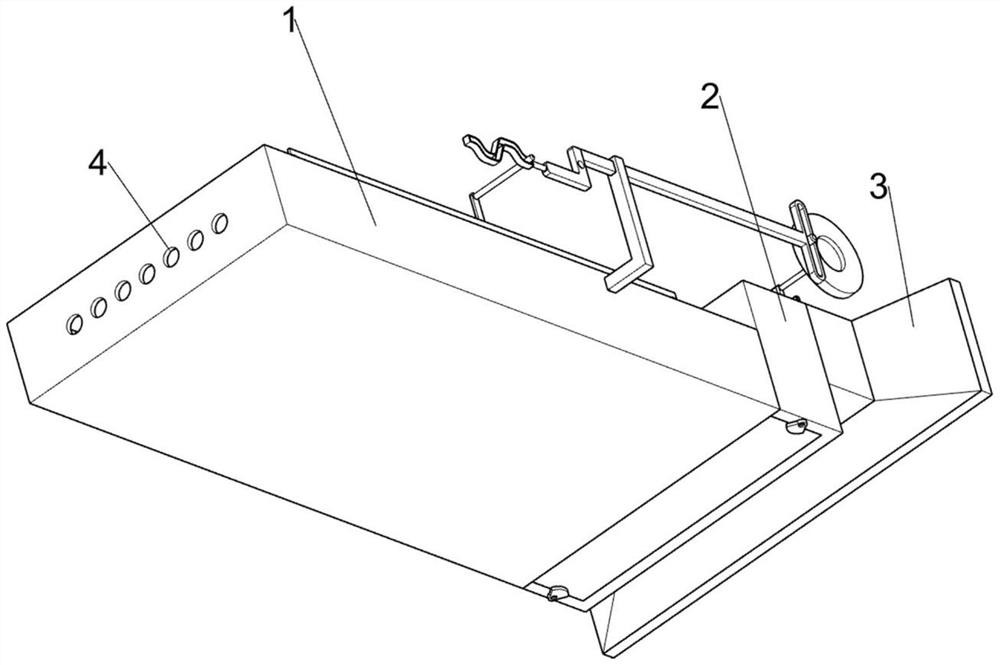

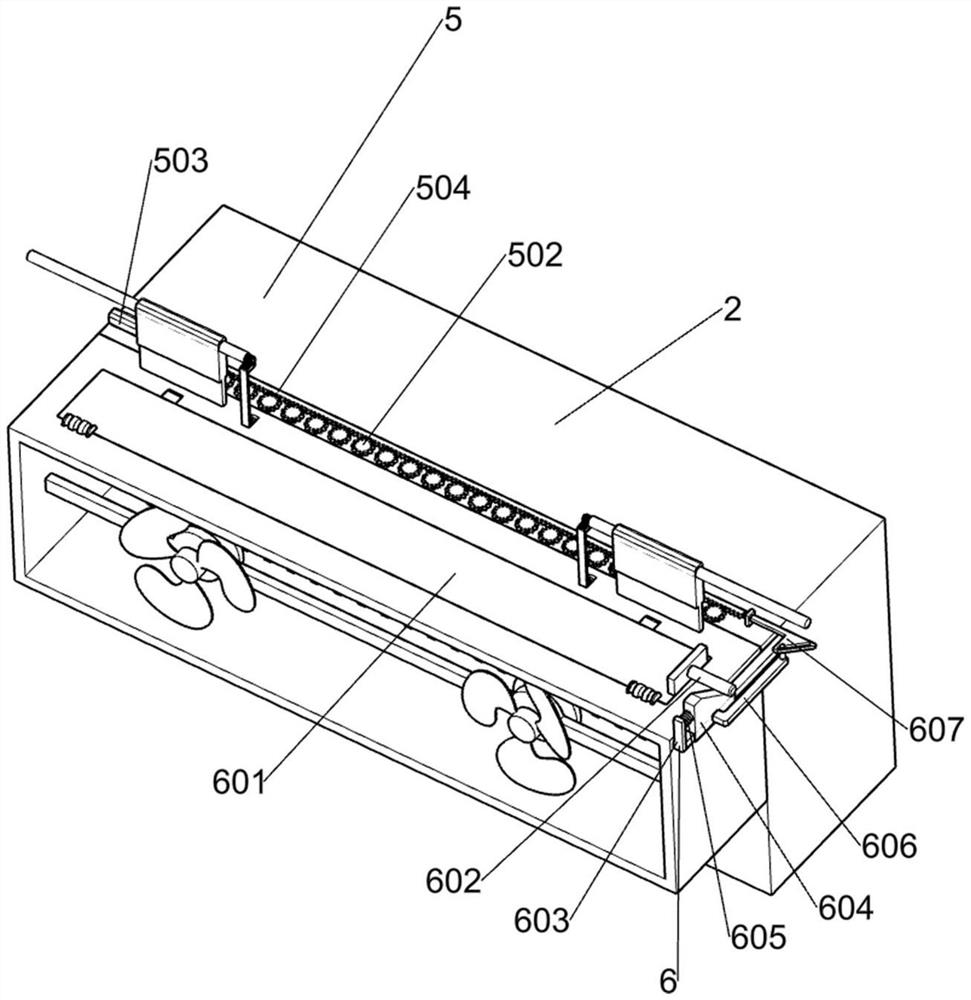

[0025] A battery pack housing assembly that utilizes high velocity airflow for auxiliary heat dissipation, such as Figure 1-8 As shown, it includes a battery pack case 1, an L-shaped frame 2, a filter screen 3, an air intake control component 5, an exhaust port control component 6, a reciprocating pull component 7 and an auxiliary heat dissipation component 8. The battery pack case 1 is installed On the inner frame of the car, an L-shaped frame 2 is installed on one side of the battery pack housing 1, and a filter screen 3 is installed on one side of the L-shaped frame 2. The filter screen 3 is installed on the front cabin of the car, and the filter screen 3 is used for To prevent foreign matter in the air from entering the L-shaped frame 2, an air vent 4 is provided on the side of the battery pack case 1 away from the L-shaped frame 2, and an air intake control component 5 is provided on the L-shaped frame 2 to control the intake air volume. The component 5 is used to contro...

Embodiment 2

[0036] On the basis of Example 1, such as Figure 4 As shown, it also includes a filter cover 9 and a support plate 10. The filter cover 9 is set inside the L-shaped frame 2. The filter cover 9 is used to fully absorb the water in the air, and the bottom of the L-shaped frame 2 away from the rack plate 504 passes through The rotating shaft is symmetrically connected with a support disc 10, and the support disc 10 is used to facilitate the replacement of new active carbon blocks and sponge blocks.

[0037] Activated carbon blocks and sponge blocks are arranged in the filter cover 9. Through the cooperation of the activated carbon blocks and the sponge blocks, the filter cover 9 fully absorbs the water in the air to prevent moisture from flowing into the battery pack and cause a short circuit. When activated carbon block and sponge block are replaced, support disc 10 is rotated 180 degrees, filter cover 9 is taken out from L-shaped frame 2, and new activated carbon block and spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com