Wire harness wall-passing structure and installation method thereof

A wire harness and over-the-wall technology, which is applied to the wire harness over-the-wall structure and its installation field, can solve the problems of insufficient sealing and inapplicability, and achieve the effect of improving the sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

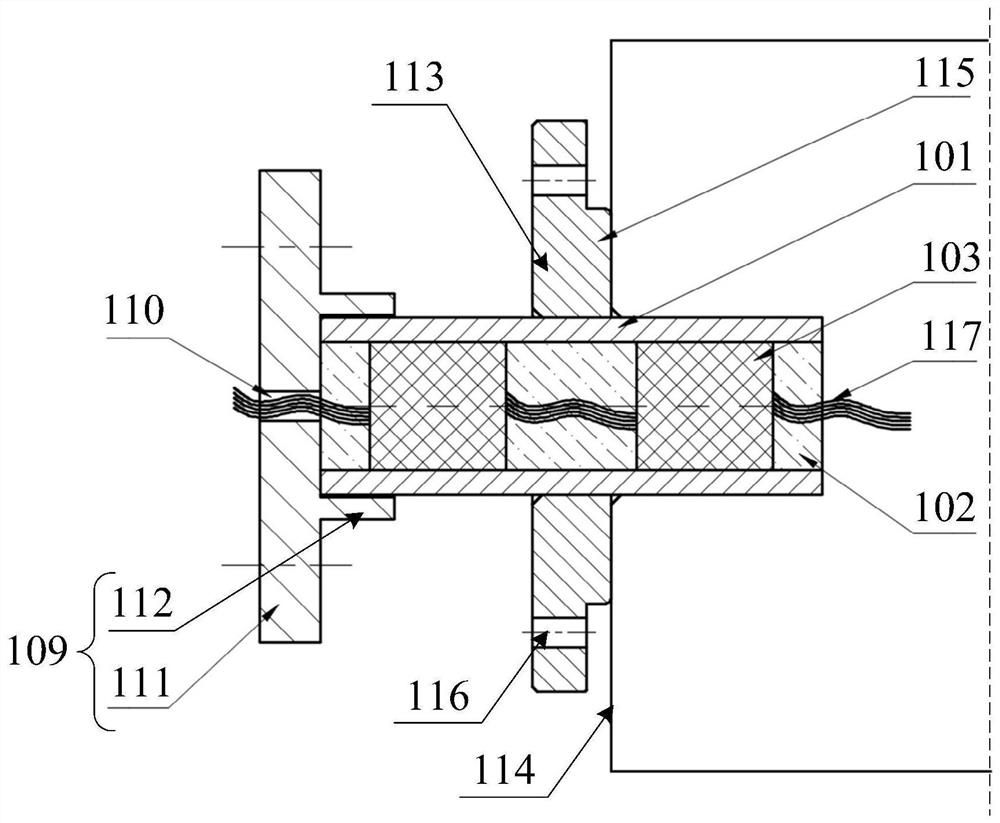

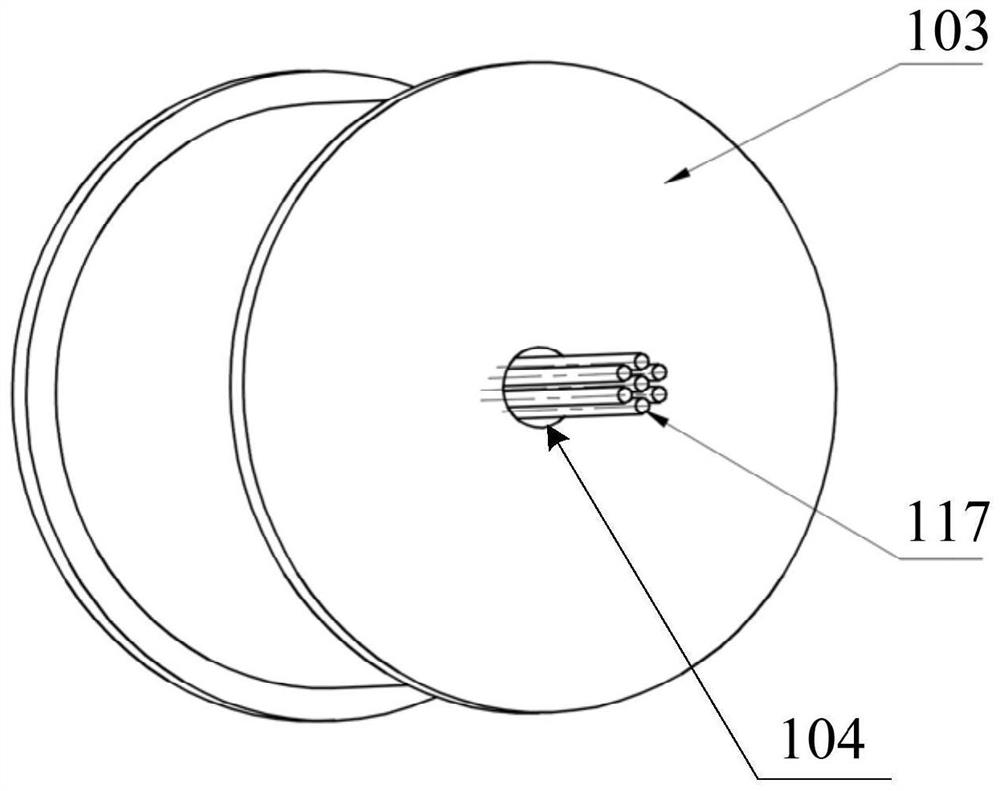

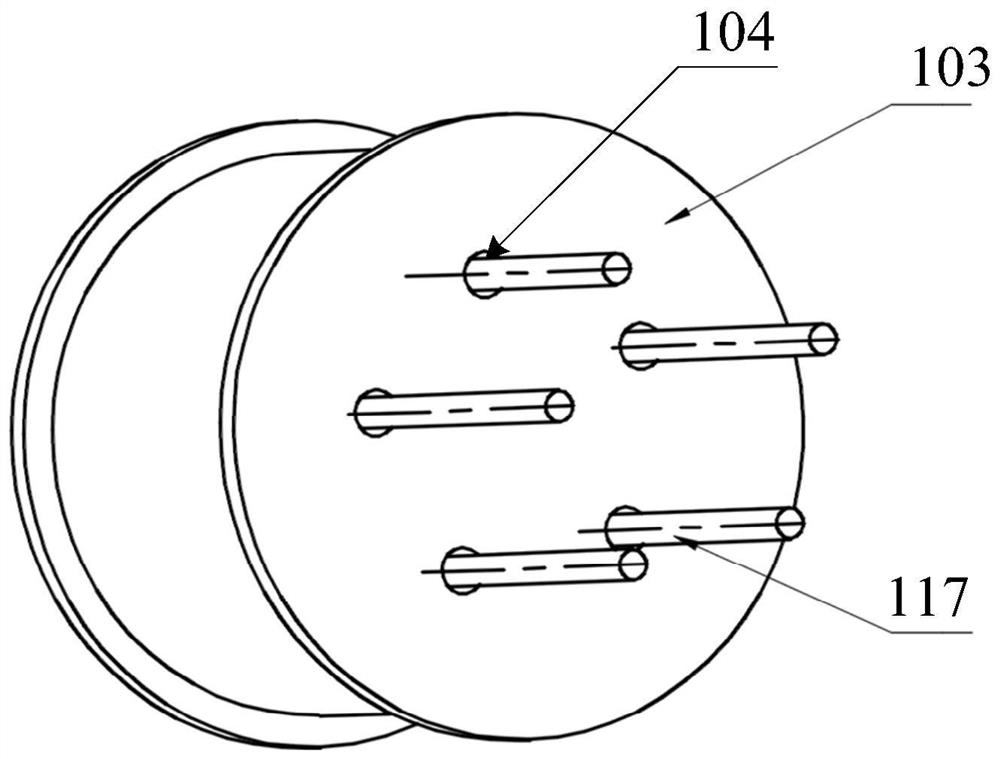

[0042] see Figure 1 to Figure 4 As shown, the harness wall structure provided by the present application includes a sleeve 101, a potting compound 102, and at least one sealing plug 103; along the axial direction of the bushing 101, the potting compound 102 and sealing plug 103 are alternately filled in the bushing 101 The sealing plug 103 is provided with at least one first through hole 104 , and the wiring harness 117 can pass through the potting compound 102 and the first through hole 104 of the sealing plug 103 .

[0043] Specifically, the wire harness passing wall structure includes a sleeve 101 , a potting compound 102 and a sealing plug 103 , wherein the sleeve 101 can pass through the wall plate of the high-pressure container waiting for the fixing device 114 . The potting compound 102 and the sealing plug 103 are arranged alternately to seal and fill the wiring cavity inside the bushing 101 .

[0044] In the specific operation, firstly, a plurality of wiring harness...

Embodiment 2

[0058] The wire harness wall-passing structure in the second embodiment is an improvement on the basis of the above-mentioned embodiment. The technical content disclosed in the above-mentioned embodiment will not be described repeatedly, and the content disclosed in the above-mentioned embodiment also belongs to the content disclosed in the second embodiment.

[0059] In the optional solution of this embodiment, at least one end of the sleeve 101 is installed with a sealing flange 109, and the sealing flange 109 is provided with a second through hole 110 corresponding to the first through hole 104, and the wire harness 117 can pass through the second through hole. Hole 110.

[0060] In this example, see figure 1 As shown, optionally, a sealing flange 109 is installed only at one end of the casing 101 outside the high-pressure vessel, so as to prevent external water vapor from entering the high-pressure vessel, and relatively save costs. Corresponding to the sealing plug 103, ...

Embodiment 3

[0072] Embodiment 3 of the present application provides an electrical device, which includes the wire harness wall-passing structure of any one of the above embodiments, and thus has all the beneficial technical effects of the wire harness wall-passing structure of any one of the above-mentioned embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com