Composite multistage seal gate valve operation method

An operation method and composite technology, applied in the direction of valve operation/release device, sliding valve, valve details, etc., can solve the problems of poor sealing reliability and achieve the effect of improving sealing performance and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

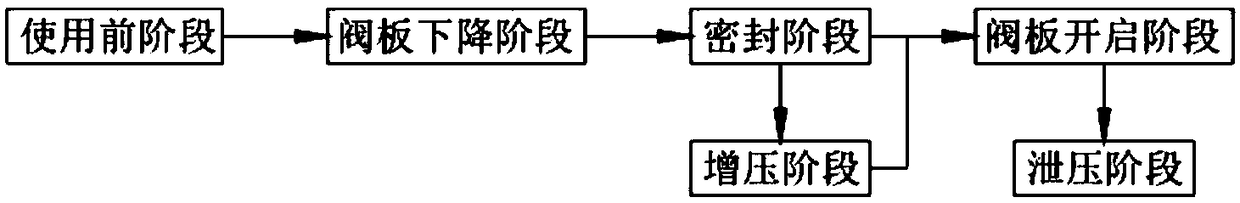

[0035] According to the manual attached figure 1 Describe the operation method of a composite multi-stage sealed gate valve in this embodiment, including the following steps:

[0036] (a) In the pre-use stage, the two ends of the medium channel 11 on the gate valve 1 are respectively sealed and connected to the medium inlet pipe and the medium output pipe for medium transmission;

[0037] (b) During the valve plate descending stage, the driving assembly 51 on the rotating lifting mechanism 5 drives the valve plate 4 to move down...

Embodiment 2

[0044] Wherein, the same or corresponding parts as those in the first embodiment adopt the reference numerals corresponding to the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below; the difference between the second embodiment and the first embodiment is that Step (c) also includes a pressurization stage, when the sealing disc 4122 extends into the medium flow channel 11, the pressurization assembly 413 on the valve plate 4 pressurizes the fluid in a movement opposite to the direction of fluid flow. The sealing plate 4132 on the pressurization assembly 413 is moved by the reverse pressure of the fluid, and after the fluid enters the moving space 414 through the drainage hole 4131 on the pressurization assembly 413, the sealing plate 4132 resets and closes the drainage hole 4131.

[0045] Wherein, the sealing plate 4132 is compressed by the fluid and at the same time the compression member 4133 on the pressurization ...

Embodiment 3

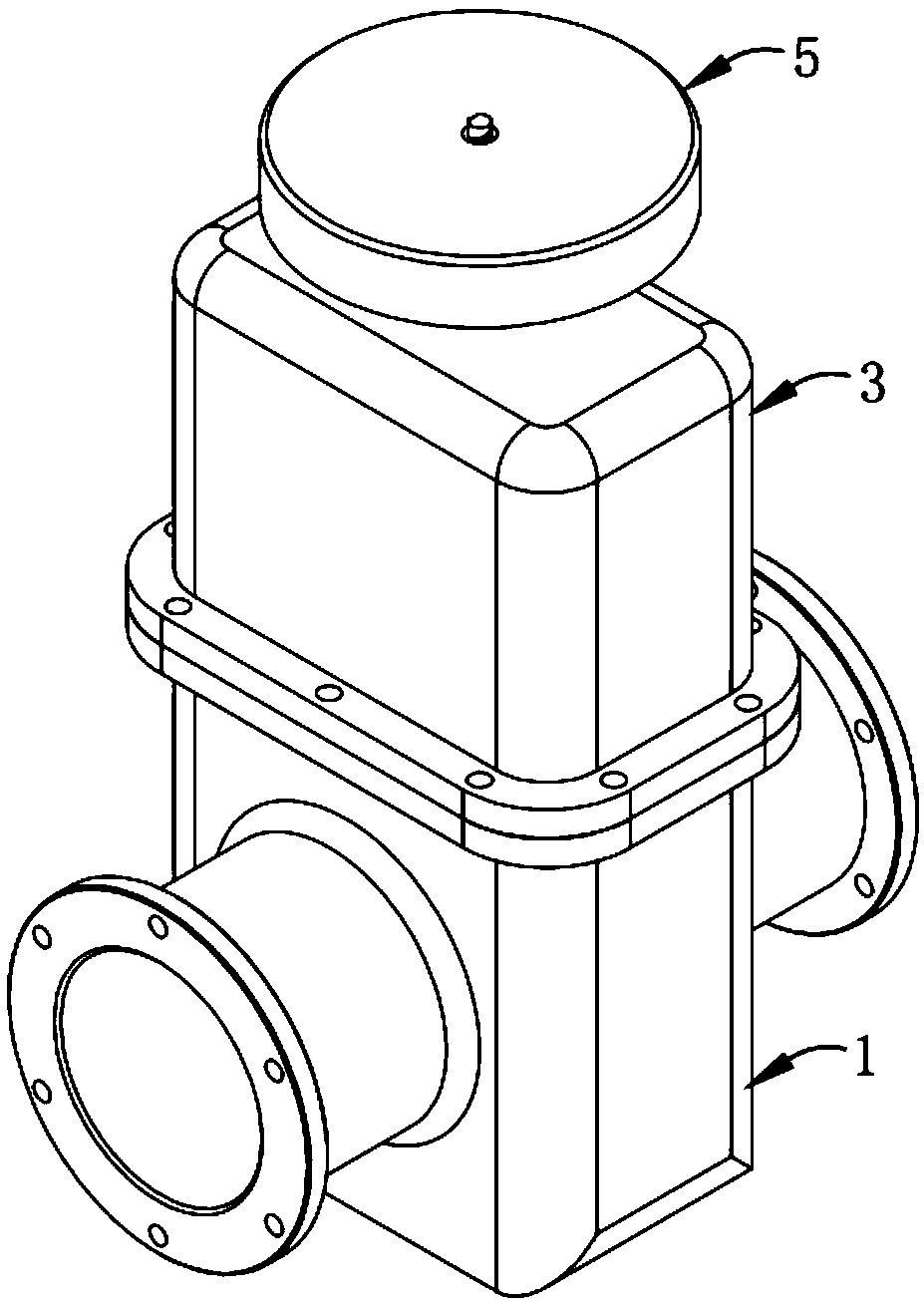

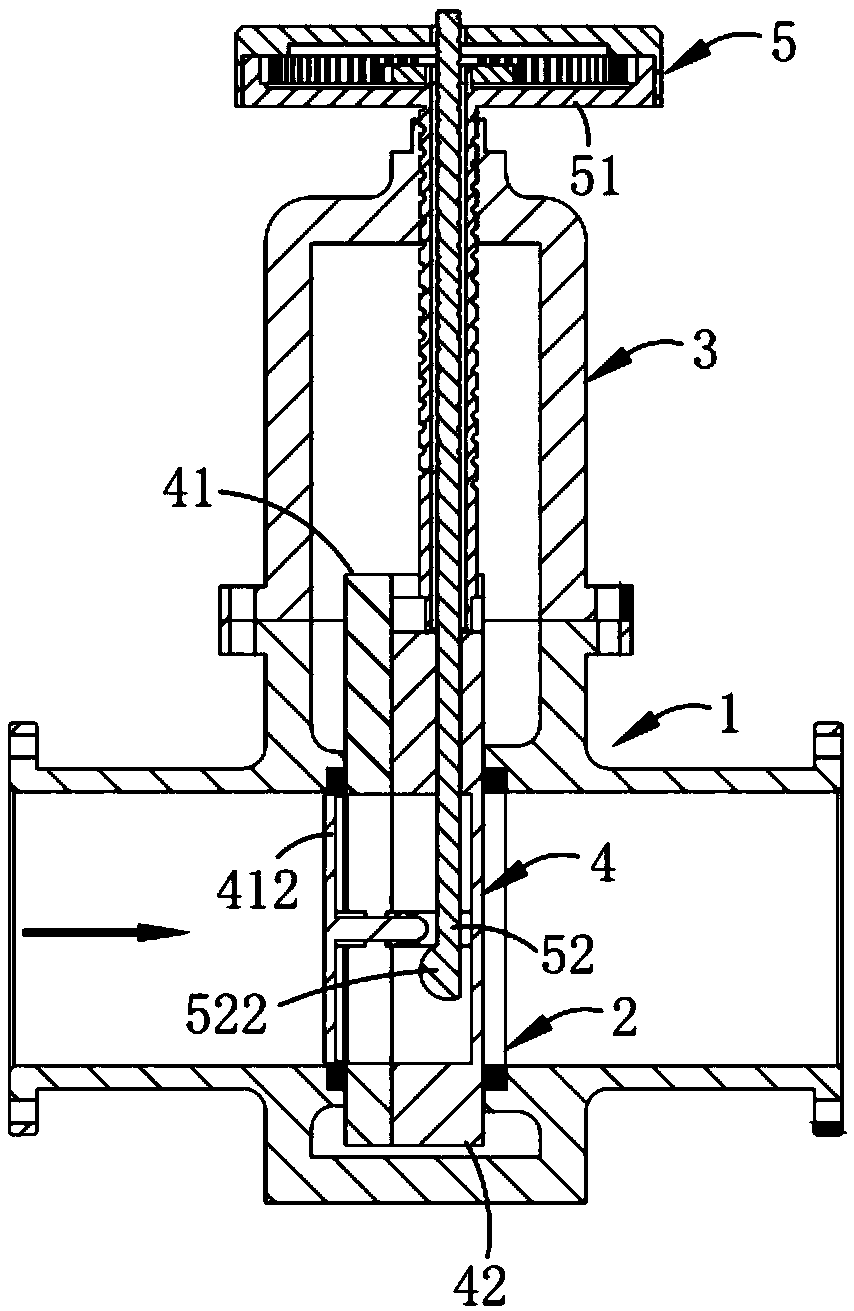

[0048] According to the manual attached Figures 2 to 9 A compound type multi-stage hermetic gate valve in this embodiment is described.

[0049] Such as Figures 2 to 6 As shown, a composite multi-stage sealing gate valve includes a valve body 1, a valve seat 2 disposed in the valve body 1, and a cover body 3 installed on the valve body 1, and also includes:

[0050] Valve plate 4, described valve plate 4 is installed in the valve seat 2 that is symmetrical structure, and it comprises main plate 41 and the auxiliary plate 42 that is connected with this main plate 41, and described main plate 41 comprises plate body 411, is arranged on this plate body 411 and the sealing assembly 412 arranged in cooperation with the medium flow channel 11 on the valve body 1 and the pressurization assembly 413 provided in intermittent communication with the medium flow channel 11, the sealing assembly 412 and the sub-plate 42 A moving space 414 for the movement of the booster assembly 413 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com