A level conversion circuit

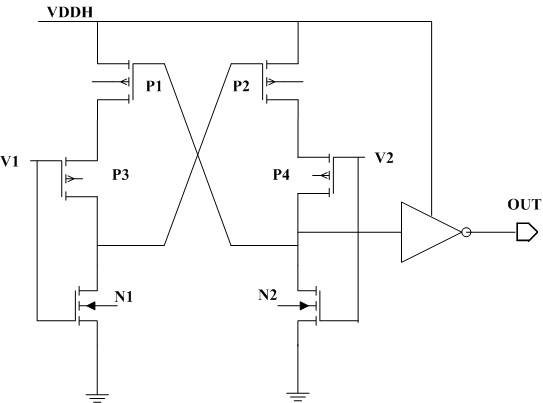

A technology for converting circuits and levels, applied in the directions of logic circuits, logic circuit interface devices, logic circuit connection/interface layout, etc., can solve problems such as the inability to solve the withstand voltage problem, the inability of NMOS transistors N1 and N2 to conduct, and achieve the realization of The effect of wide power supply voltage, realization of conversion, and avoidance of withstand voltage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0019] The present invention will be further described below with reference to the accompanying drawings.

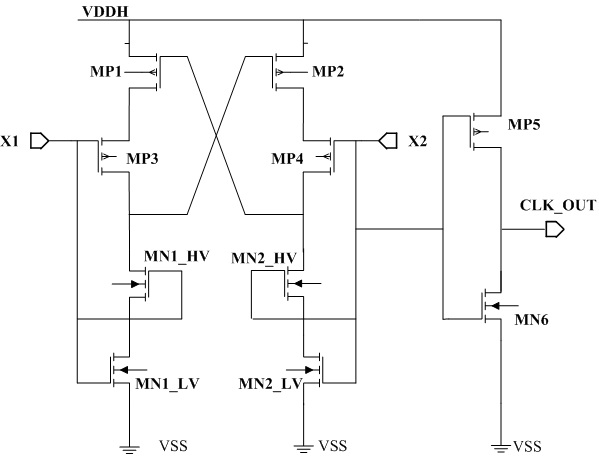

[0020] A level shifting circuit such as figure 2 As shown, it includes a first field effect transistor MP1 and a second field effect transistor MP2 connected to the power supply voltage VDDH, a third field effect transistor MP3 connected to the first input terminal X1, a first high voltage native transistor MN1_HV and a first low voltage field effect transistor. Effect transistor MN1_LV, the fourth field effect transistor MP4 connected to the second input terminal X2, the second high voltage native transistor MN2_HV and the second low voltage field effect transistor MN2_LV, the fourth field effect transistor MP4 and the second high voltage native transistor MN2_HV and the second low voltage field effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com