A radiation-resistant semiconductor device terminal structure

A terminal structure and semiconductor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of degradation of electrical characteristics in the active area, failure to slow down the degradation of electrical characteristics in the terminal area, and the impact of the terminal area of the device, so as to solve the terminal withstand voltage problems, improving the surface electric field, and avoiding the effects of breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

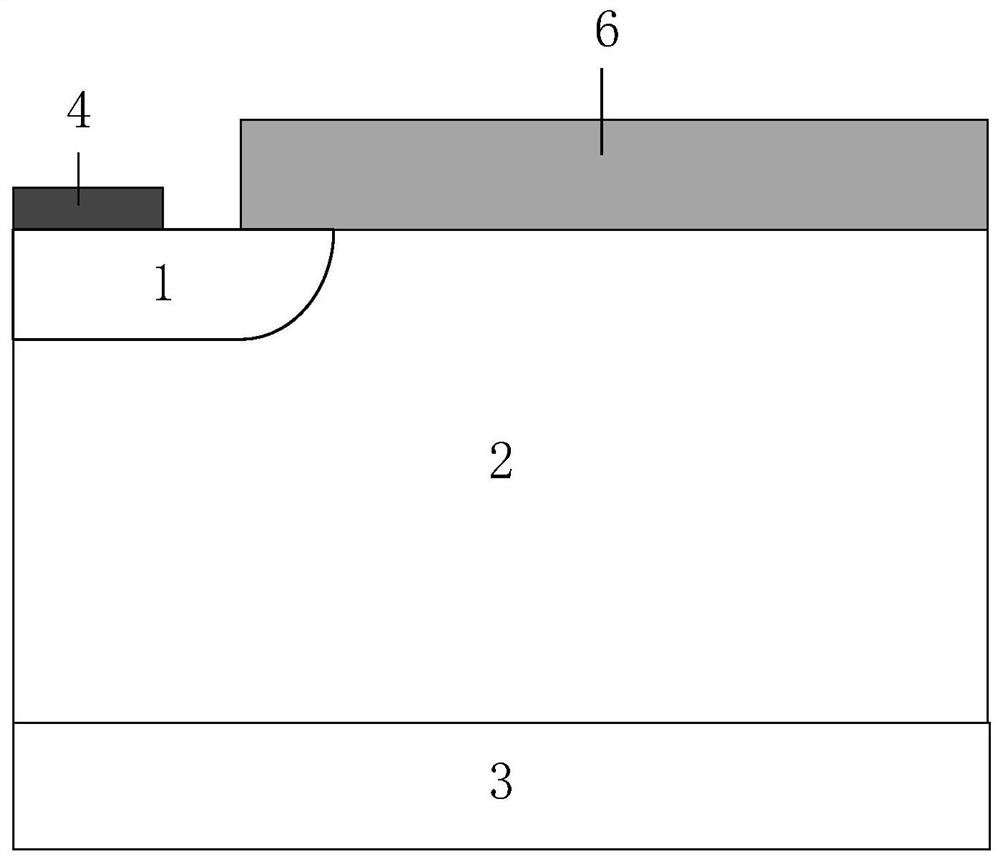

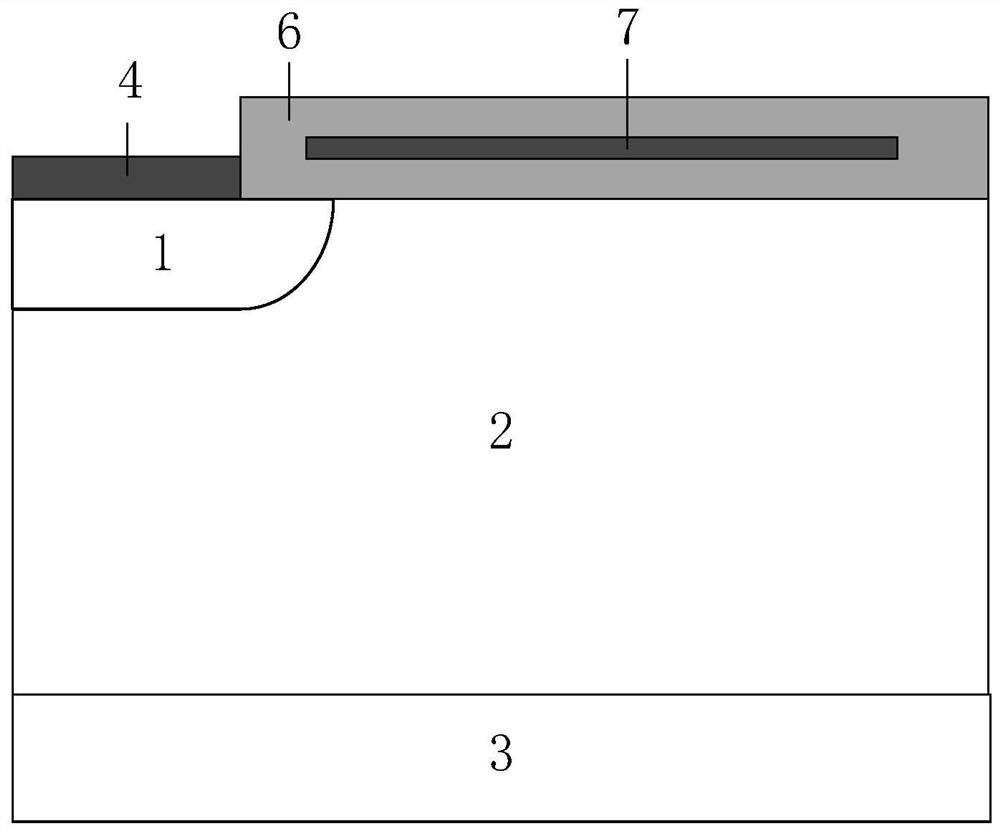

[0033] Such as figure 2 As shown, it includes a first conductivity type semiconductor substrate 3, a first conductivity type semiconductor drift region 2 located on the upper surface of the first conductivity type semiconductor substrate 3, and a first conductivity type semiconductor drift region 2 formed in the first conductivity type semiconductor drift region 2. Cell region extension well 1 of two conductivity types; the upper surface of semiconductor drift region 2 of the first conductivity type and part of the upper surface of cell region extension well 1 of the second conductivity type have an insulating layer 6, and the first metal electrode 4 is located on Part of the upper surface of the cell region of the second conductivity type extending well 1, the polysilicon strip 7 is located on the upper surface of the semiconductor drift region 2 of the first conductivity type and the insulation of part of the upper surface of the cell region of the second conductivity type e...

Embodiment 2

[0048] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the polysilicon strips 7 are intermittently distributed in the lateral direction, and this structure will further improve the radiation resistance of the terminal. A plurality of discontinuous polysilicon strips will modulate the terminal electric field in a non-radiative state and improve the withstand voltage of the device.

[0049] As a preferred manner, the distances between the discontinuous portions of the polysilicon strip 7 in the lateral direction and the upper surface of the drift region 2 of the semiconductor of the first conductivity type are different.

Embodiment 3

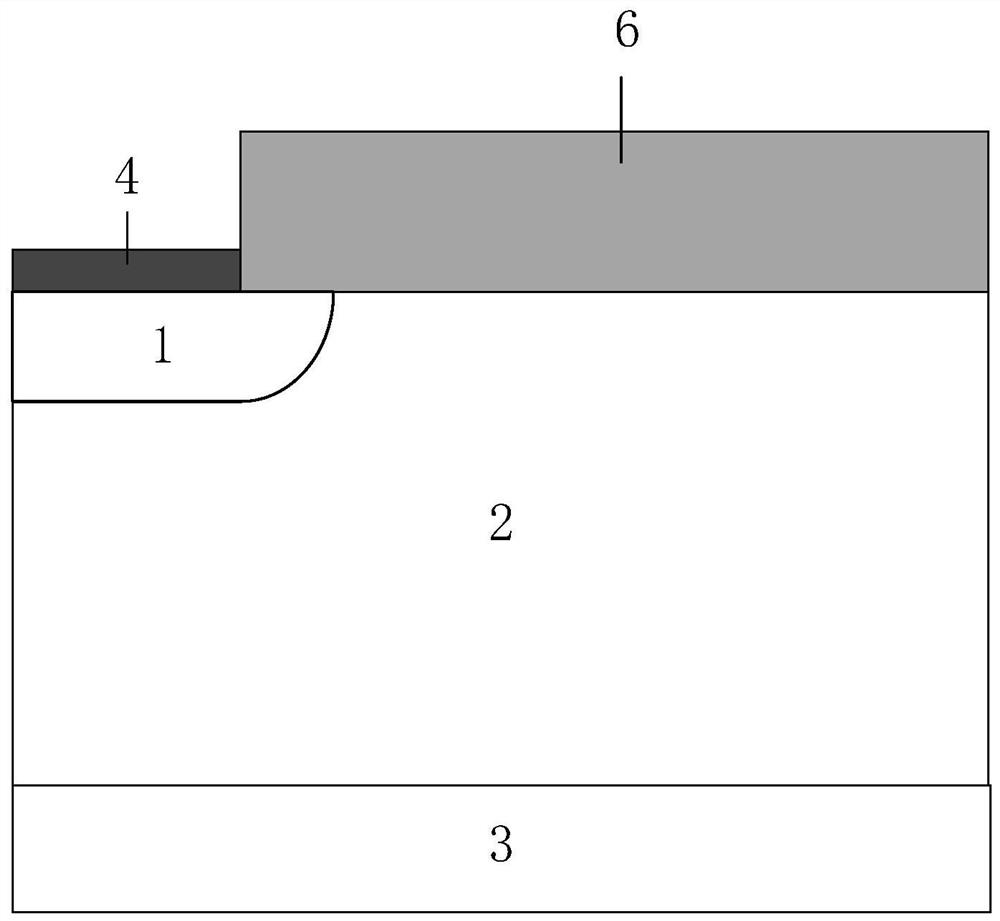

[0051] Figure 5An application example of this embodiment to a planar gate is given, indicating that the present invention can be applied to various vertical device structures.

[0052] In addition, the coverage, width and number of polysilicon strips can be adjusted according to the process conditions. Multiple polysilicon strips or thickened polysilicon strips will improve the radiation resistance of the terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com