Thermophilic bio-trickling gas-liquid two-phase device and application thereof in removal of heavy metals in flue gas

A technology of thermophilic organisms and heavy metals, applied in gas treatment, air quality improvement, membrane technology and other directions, can solve the problems of short service life of filter material, small processing load, poor removal effect of heavy metals in waste gas, etc. Synergistic control to solve the effect of easy saturation of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 A kind of thermophilic biological trickling filter gas-liquid two-phase device

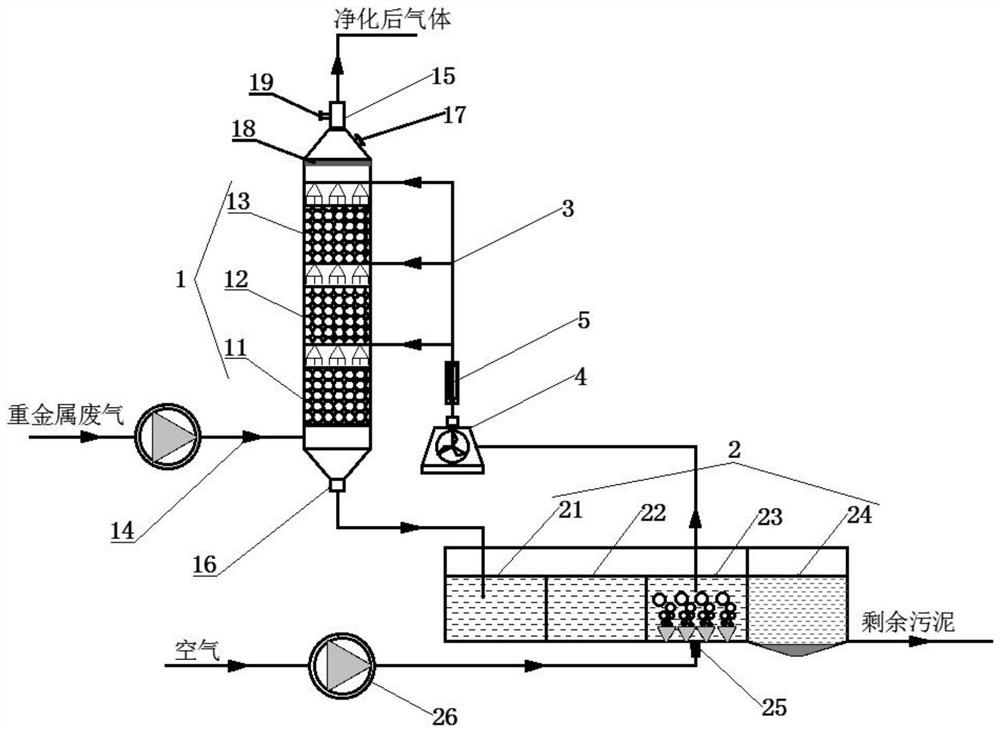

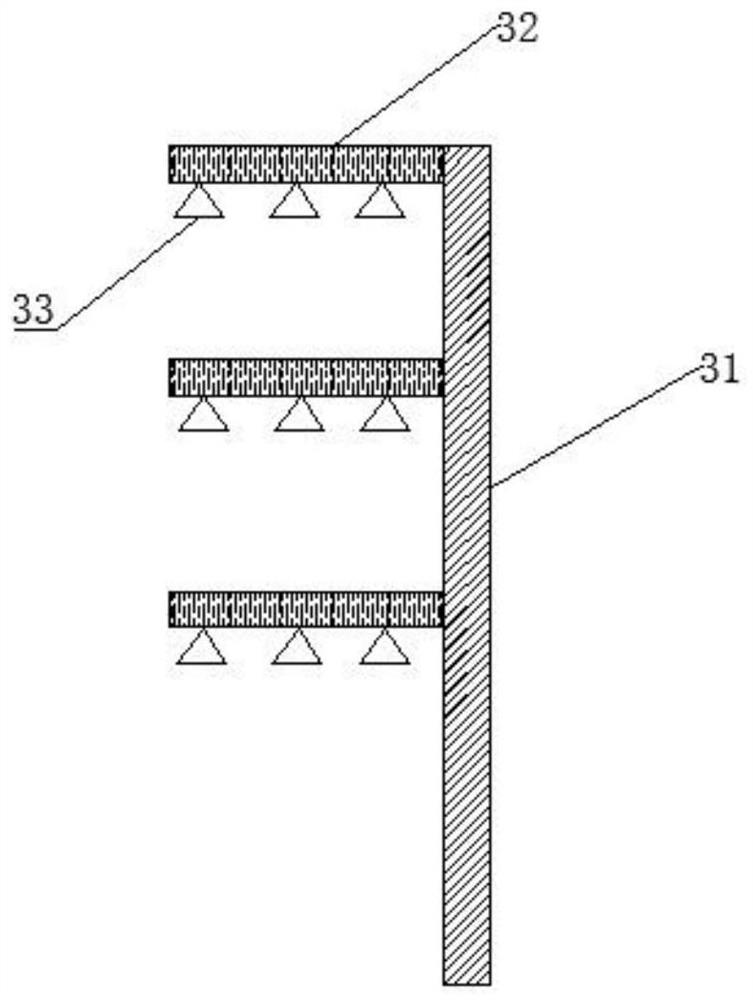

[0032] Such as figure 1 and figure 2 As shown, the thermophilic bio-trickling filter gas-liquid two-phase device includes a thermophilic bio-trickling filter unit 1 and an AA / O unit 2, and the thermophilic bio-trickling filter unit 1 is tower-shaped, sequentially from bottom to top Including the first-level filler layer 11, the second-level filler layer 12 and the third-level filler layer 13 (a total of three-level filler layers, the filler layer can be filled with inorganic fillers, organic fillers, or mixed fillers), each level of the filler There are biofilms attached to the layers, and the biofilms are divided into aerobic zone, anoxic zone and anaerobic zone. The biofilms are added with high-temperature-resistant special-effect denitrifying bacteria and sulfate-reducing bacteria. The denitrifying Bacteria and sulfate-reducing bacteria can withstand higher temperatures (...

Embodiment 2

[0045] Example 2 A biotransformation method for denitrification and desulfurization of heavy metals in flue gas—Using the thermophilic biological trickling filter gas-liquid two-phase device of Example 1 to treat heavy metal-containing flue gas after sludge co-incineration

[0046] When municipal sludge is co-incinerated with papermaking bottom slag and pulp slag solid waste incinerator, sulfur dioxide, smoke dust, nitrogen oxides, hydrogen chloride, and a small amount of flue gas such as mercury, lead, and dioxins will be produced. The flue gas after sludge co-incineration in a sludge incineration plant was tested. The concentrations of heavy metals Hg, Pb, As, Cd, and Cr in the flue gas were 0.04, 0.63, 30.78, 0.01, and 0.77mg / m3 respectively. 3 The above-mentioned flue gas is discharged after being treated by "selective non-catalytic reduction flue gas denitrification+bag dust removal+rotary spray semi-dry deacidification device+bag dust removal+biological dripping filter de...

Embodiment 3

[0048] Example 3 A biotransformation method for denitrification and desulfurization of heavy metals in flue gas—Using the thermophilic biological trickling filter gas-liquid two-phase device of Example 1 to treat heavy metal-containing waste gas after sludge drying

[0049] Sludge drying will decompose many organic matters in the sludge, causing odor pollution. The waste gas temperature is high, the odor concentration is high, and the composition is complex: acid gas pollutants (sulfur dioxide, nitrogen oxides), sulfur-containing odor compounds ( Hydrogen sulfide, methyl mercaptan, methyl sulfide, etc.), nitrogen-containing malodorous compounds (ammonia, amines), hydrocarbons and organic substances (including dioxins), and heavy metals. The flue gas after sludge drying in a sludge drying plant has been tested, and the concentrations of heavy metal mercury and Pb+As+Cd+Cr+Cu+Zn in the flue gas are 27.5 and 46.8mg / m3 respectively 3 , the above-mentioned sludge drying flue gas ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com