Quantitative proportioning type feed stirring system and stirring process for livestock raising

A feed mixing and feed technology, which is applied to feed, mixer accessories, mixers with rotating mixing devices, etc., can solve the problems of time-consuming and laborious, lack of quantitative ratio of feed, and inaccurate manual control of feed amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

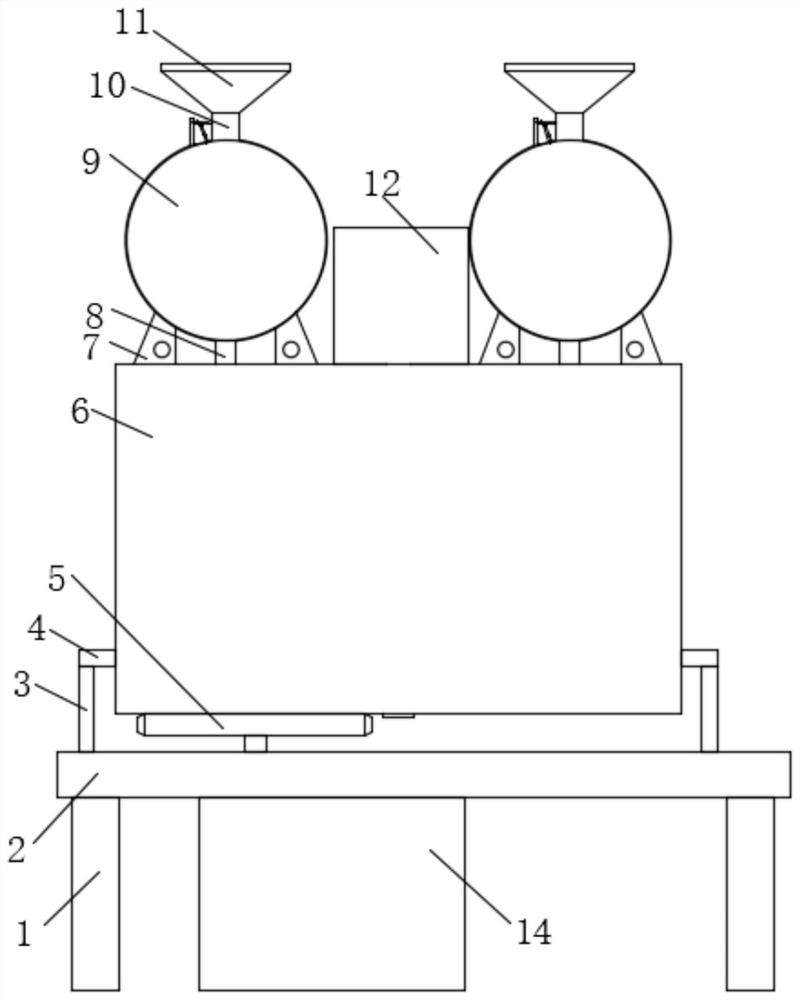

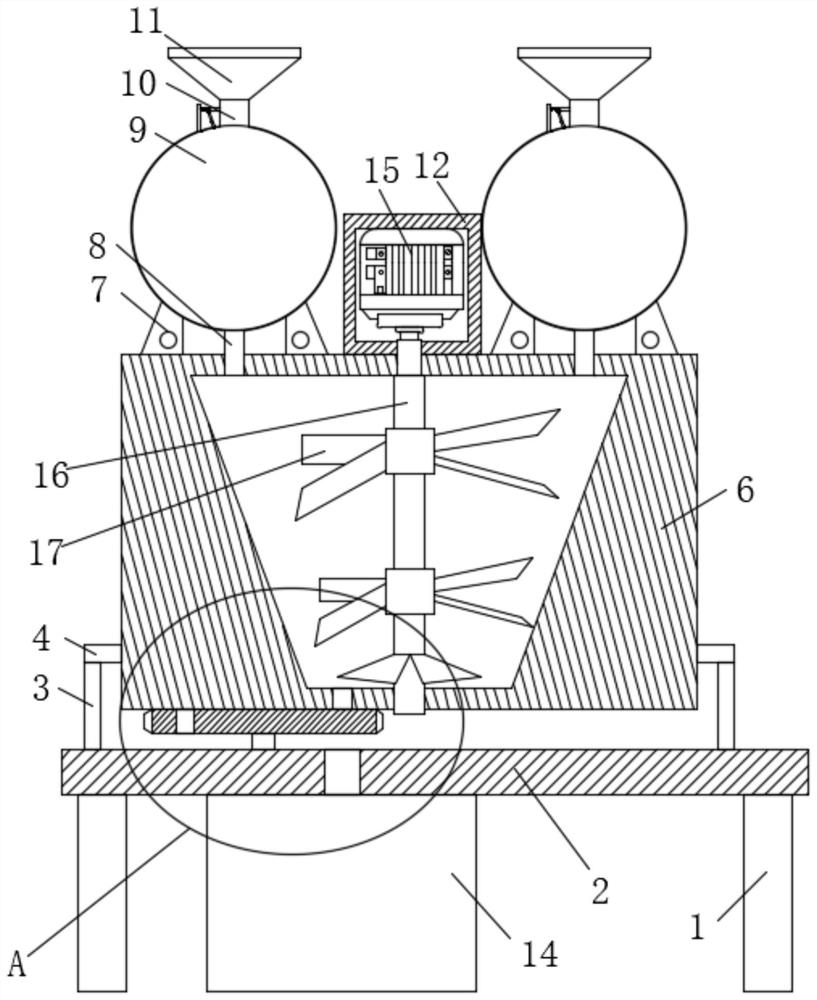

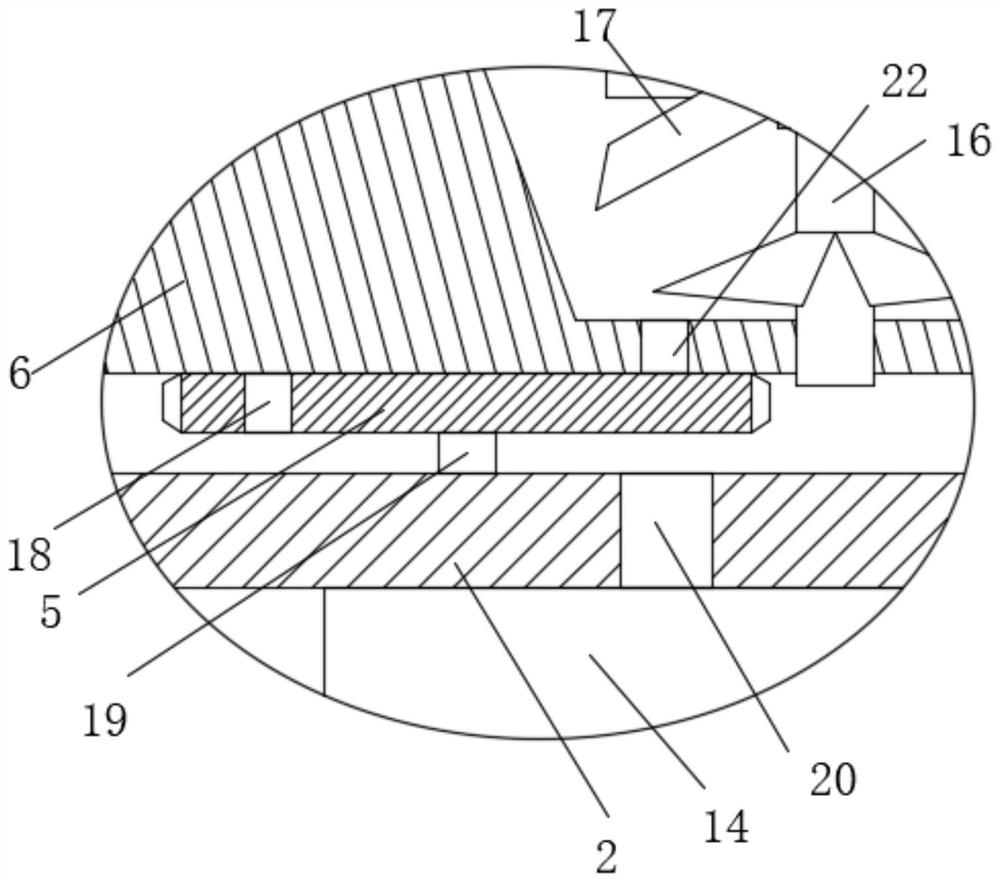

[0048] Embodiment one: if Figure 1-13 As shown, a quantitative proportioning feed mixing system for animal husbandry includes a third support plate 2, the four corners of the bottom of the third support plate 2 are fixedly connected with support columns 1, and the top of the third support plate 2 is provided with a discharge Assemblies, the top of the third support plate 2 is fixedly connected with two symmetrically arranged vertical plates 3, the tops of the two vertical plates 3 are fixedly connected with a horizontal plate 4, and the sides of the two horizontal plates 4 close to each other are fixedly connected with the same A mixing box 6, the inside of the mixing box 6 is provided with a mixing assembly for stirring the feed, the top of the mixing box 6 is fixedly connected with two symmetrically arranged two support bases 7, and the tops of the two supported bases 7 are fixedly connected with the same An outer circular box 9, the inside of the outer circular box 9 is pr...

Embodiment 2

[0064] Embodiment two: if Figure 14-18 Shown; a quantitative proportioning feed mixing system for animal husbandry, the difference between this embodiment and embodiment one is: the top of the third support plate 2 is connected to the second rotating rod 21, and the top of the second rotating rod 21 is connected to the The bottom of stirring rod 16 is fixedly connected, and the outer wall fixed cover of second rotating rod 21 is provided with incomplete gear 13, and incomplete gear 13 is matched with spur gear 5, and stirring rod 16 drives second rotating rod 21 to rotate, and the second rotating rod The rod 21 drives the incomplete gear 13 to rotate, and the incomplete gear 13 contacts the spur gear 5 once every rotation, and drives the spur gear 5 to rotate until the first discharge port 18, the third discharge port 22 and the second discharge port When 20 are connected, the feed that is positioned at the bottom and has been stirred flows into the receiving box 14 for colle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap