Locking method and locking device for pressing type bottle cap

A locking device and pressing technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing production costs, failure to achieve effective connection, product scrapping, etc., and achieve the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

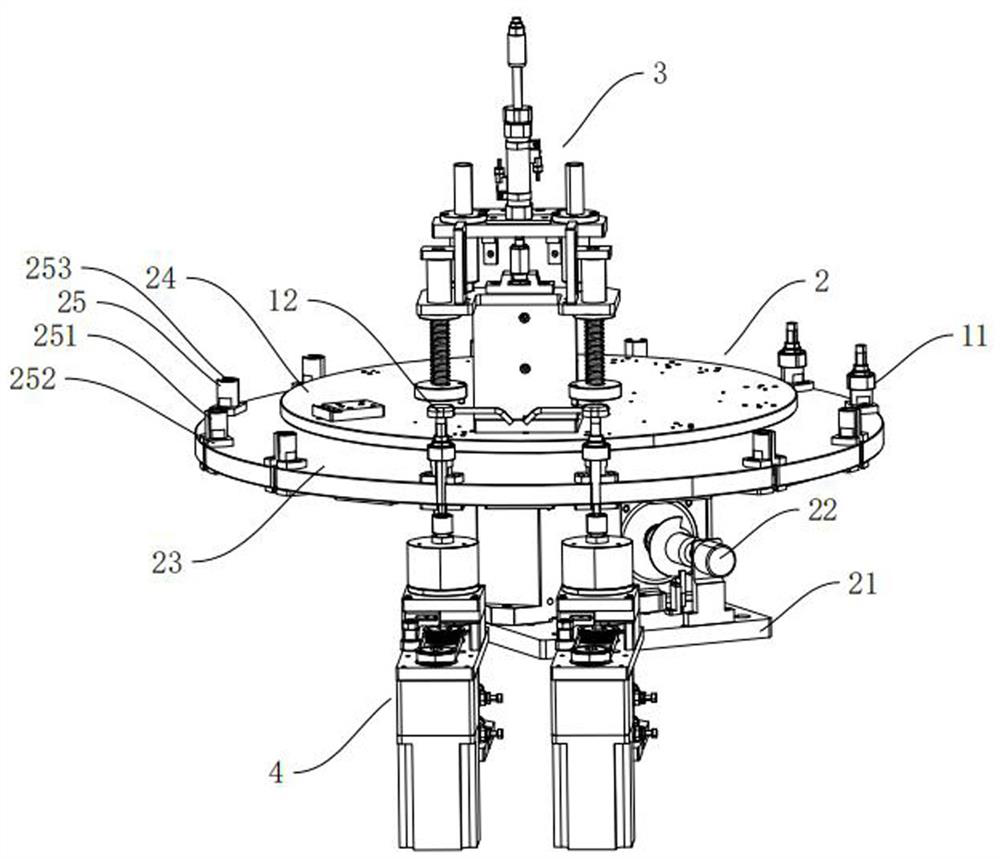

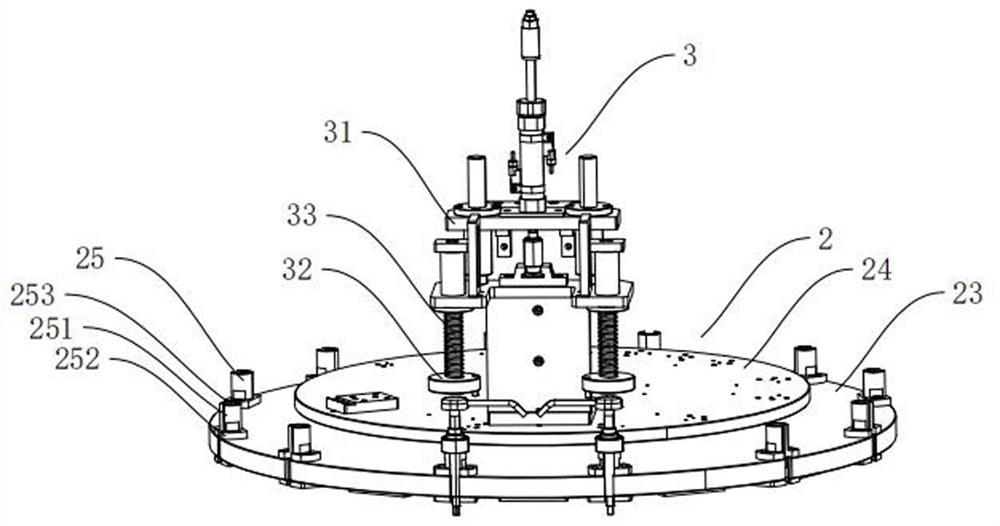

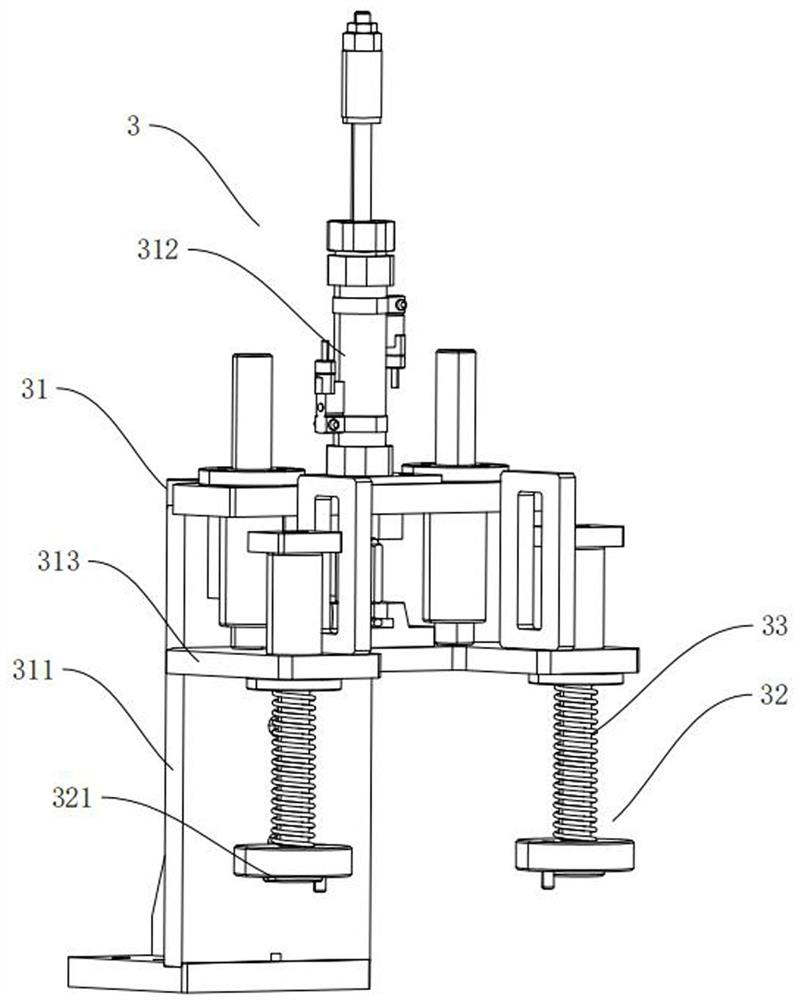

[0029] Embodiment 1: A locking method for a push-type bottle cap, the push-type bottle cap includes a bottle cap body 11, and a pressing mechanism that is provided on the bottle cap body 11 and can move along the axial direction of the bottle cap body 11 12, when the pressing member 12 moves toward the bottle cap body 11 to a locked state, the pressing member 12 is threadedly connected to the bottle cap body 11; the locking method includes:

[0030] Acting on the pressing member 12 toward the bottle cap body 11, the bottle cap body 11 is limited in its axial direction;

[0031] The bottle cap body 11 is fixedly connected with the torque sensor 42 arranged on the driving mechanism 4, and the bottle cap body 11 is driven to rotate by the torque sensor 42, so that the pressing member 12 is pressed against the The bottle cap body 11 is rotated to be threadedly connected with the bottle cap body 11 until the torque value of the torque sensor 42 on the bottle cap body 11 reaches a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com