Compound pipeline for improving pipeline strength and non-deformability of ultra-deep buried steel pipe

A composite technology with anti-deformation ability, applied in the direction of pipes/pipe joints/fittings, pipeline protection, pipeline damage/wear prevention, etc., can solve problems such as unretrieved technical solutions, increase economy and applicability, and avoid Direct contact, effect of reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

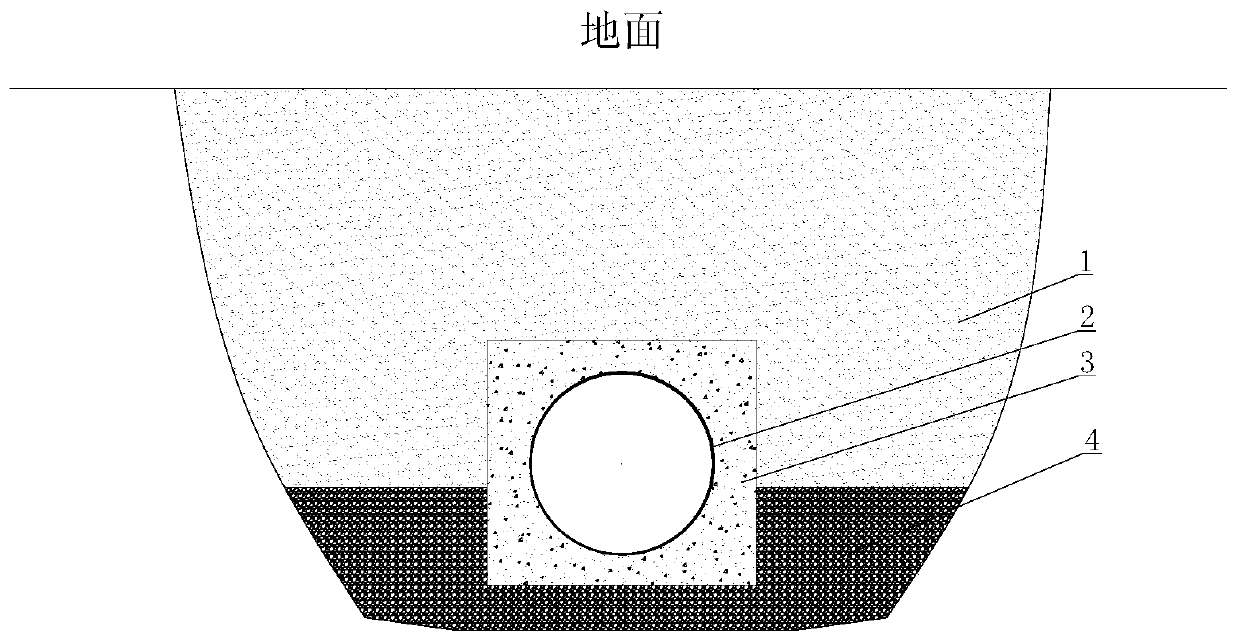

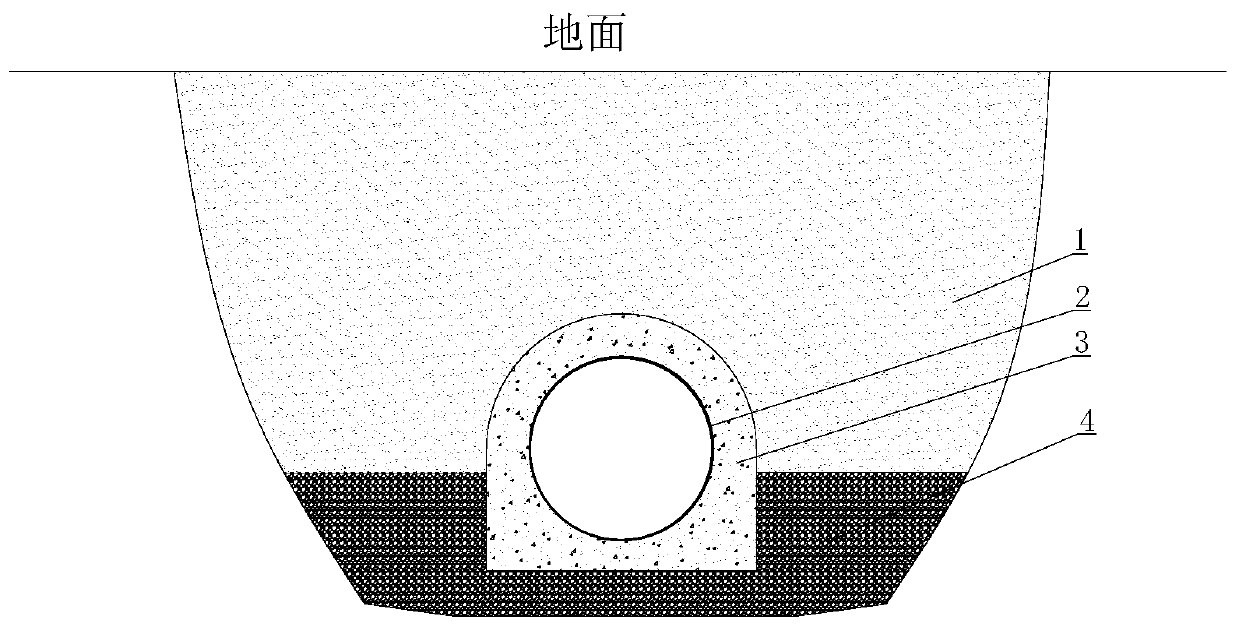

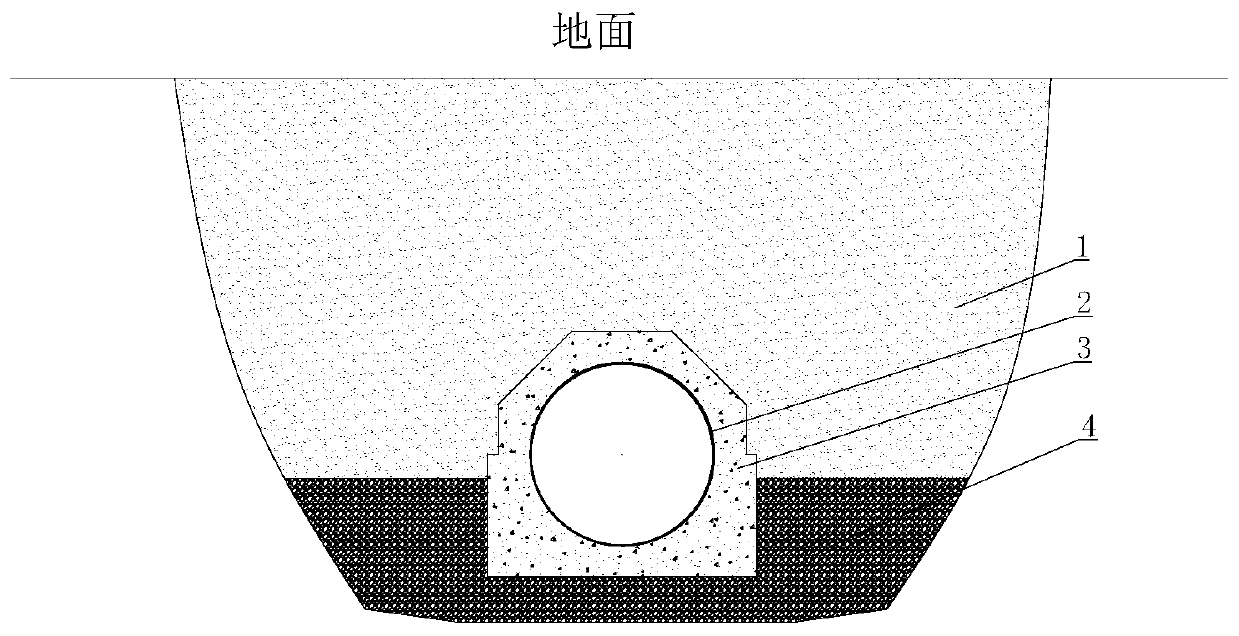

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0022] A composite pipeline that improves the strength and deformation resistance of ultra-deep buried steel pipe pipelines, the invention points of which are:

[0023] It includes a pipe body 2 and a concrete outer reinforcement sleeve 3 . The pipeline body adopts a steel pipe structure, and the concrete reinforcement sleeve is wrapped and poured on the outside of the pipeline body, specifically, C25 concrete is used for pouring. The two ends of the pipe body are exposed to the outside of the concrete reinforcement sleeve to form the joint end. For example, the length of a steel pipe is 6m, and the pouring length of the concrete reinforcement sleeve is 5.5m. In this way, the length of the two joint ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com