Imprinting device for outer wall of iron bottle for production of fruit juice

A technology for bottle caps and fruit juices, applied in the field of embossing devices, which can solve the problems of high equipment cost, inability to save time and labor, and complicated operation process, and achieve the effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

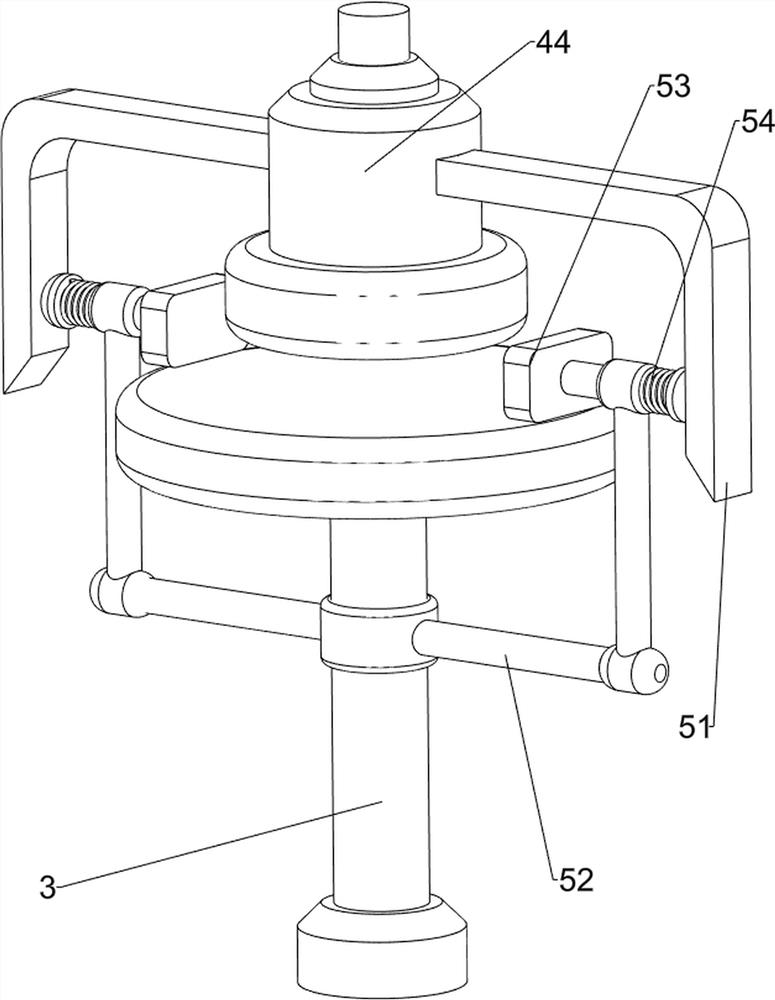

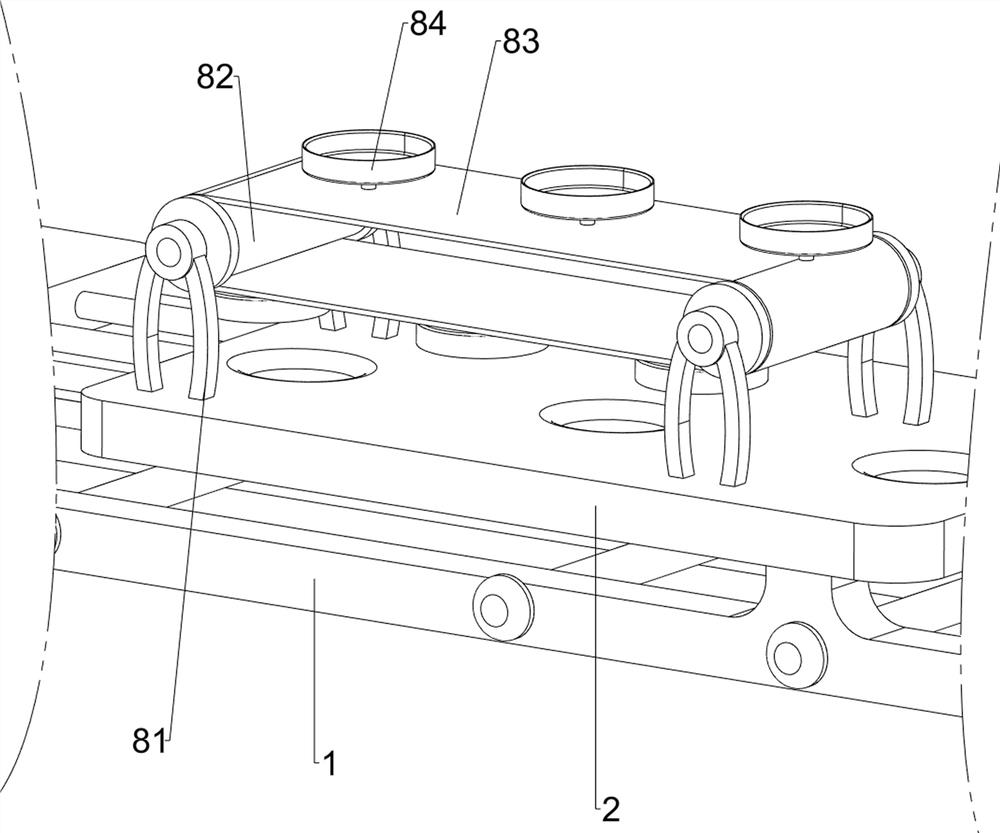

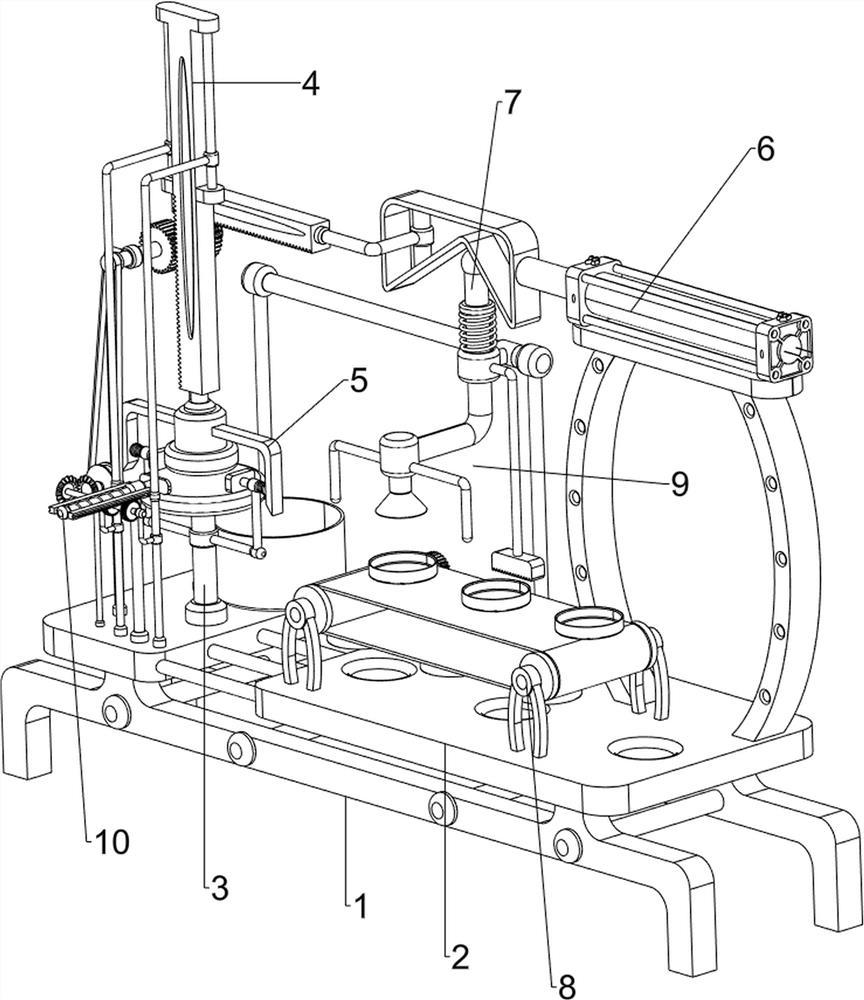

[0070] An outer wall pressure printing device for producing iron bottle of juice, such as figure 1 As shown, there is a base 1, the mounting plate 2, the support station 3, the lower pressure mechanism 4, and the clamping mechanism 5, and the top of the base 1 is provided with a mounting plate 2, and the mounting plate 2 is provided with a support station 3, and the mounting plate 2 is provided. The lower left side is provided with a lower pressure mechanism 4, and the lower pressure mechanism 4 is fitted with the support table 3, and the support table 3 and the lower pressure mechanism 4 are provided with a clamping mechanism 5.

[0071] It can be printed by the present invention, first, the operator is placed on the support table 3, followed by pressing the lower pressing mechanism 4, and the lower pressure mechanism 4 will press the cap to press the bottle cover, down pressure mechanism 4 Down movement, the clamping mechanism 5 is clamped from both sides, and after the lower p...

Embodiment 2

[0073] On the basis of Example 1, such asfigure 2 with image 3 As shown, the lower pressure mechanism 4 includes a first slip sleeve 41, a first slider 42, a first rack 43, and a printing block 44, and two first sliders 41 are provided on the front of the top of the mounting plate 2. The first slider 41 is slidably equipped with a first slider 43, and a first rack 43 is provided between the two first sliders 42, and a printing block 44 is provided at the bottom of the first rack 43.

[0074] The lower pressure mechanism 4 is moved downward, and the top of the bottle cap is imprinted. First, the operator places the bottle cover on the support table 3, and then press the first rack 43 downward, the first rack 43 moves downward. The first slider 42 slides downward on the first slider 41, so that the printing block 44 is driven down the bottle cover, the support table 3 is used to support the cap and the printing block 44, when the bottle cover is completed Thereafter, the first rac...

Embodiment 3

[0078] On the basis of Example 2, such as Figure 4 , Figure 5 , Figure 6 , Figure 7 with Figure 8 As shown, it is also included, and the push mechanism 6 includes a push mechanism 6 including a first support post 61, a cylinder 62, a second wedge block 63, a second rack 64, a second support post 65, a first spindle 66, and a first gear. 67. The first support post 61 is provided on the top right side of the mounting plate 2, and the upper portion of the first support post 61 is provided with a cylinder 62, and the second wedge block 63 is provided on the left side of the telescopic rod of the cylinder 62, and the second wedge block 63 is provided. There is a second rack 64, and the upper left side of the mounting plate 2 is provided with a second support post 65. The upper rotation of the second support post 65 is provided with a first spindle 66, and the first spindle 66 is provided with a first gear 67, first The gear 67 meshes with the first rack 43 and the second rack 64, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com