Aerial auxiliary stringing equipment

A rope-threading and equipment technology, applied in the field of unmanned aerial vehicles, can solve the problems of high labor intensity, low work efficiency, hidden safety hazards, etc., and achieve the effect of reliable operation and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

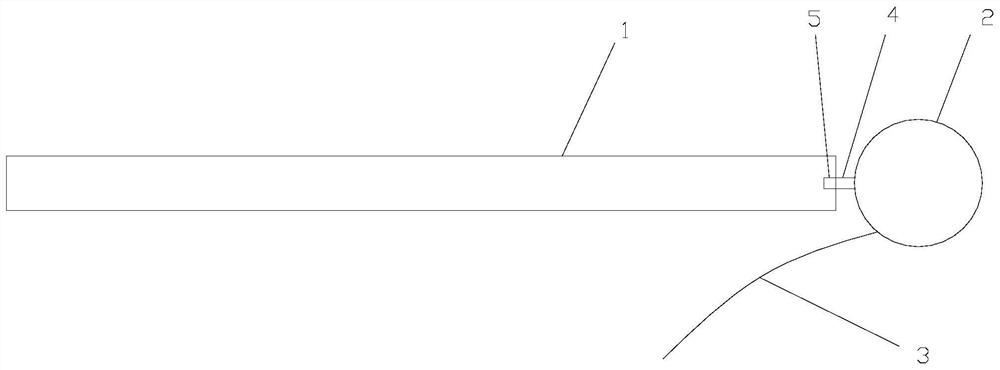

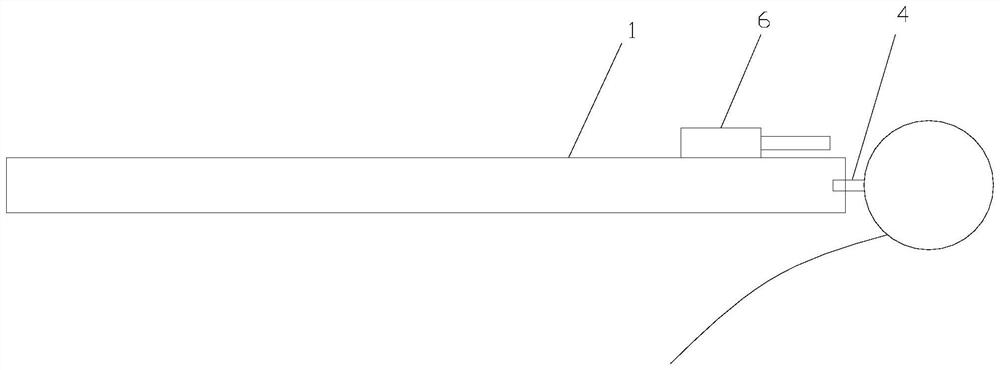

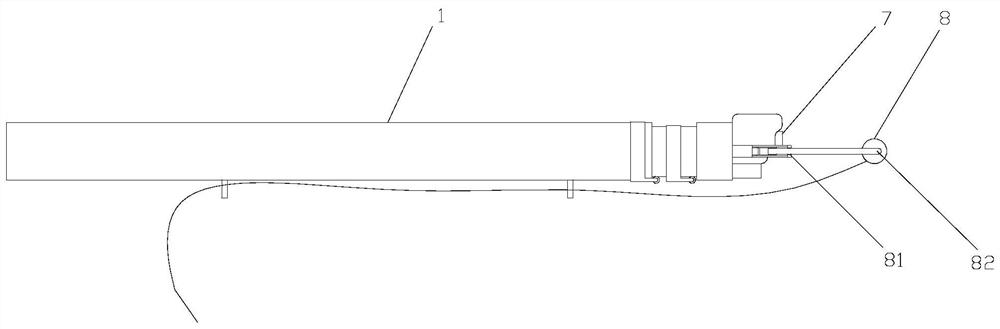

[0031] The second embodiment of the present invention is: threading the rope through the middle of the suspension ring under the action of the jaws;

[0032] When the lidar detects the lifting ring (at this time, the telescopic arm is on the side of the lifting ring), the controller controls the opening action of the jaws, and the stretching action of the telescopic arm, so that the lifting ring is located in the jaws, closes the jaws, triggers the travel switch A, and the electromagnetic The relay works, and the rope base is released from the first half shell and attracted to the second half shell;

[0033] After the two half-shells are attracted to the rope seat, the travel switch B is triggered, the jaws are opened, and the mechanical arm is retracted to complete the rope-threading action.

[0034] When in action, travel switch A sends a signal to the controller to control the electromagnetic relay to switch on and off; pull the rope seat from half shell one to half shell t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com