A turntable type freeze-dried microchip dispenser

A technology of turntable and dispenser, which is applied in the fields of biopharmaceuticals and freeze-drying. It can solve the problems of fragile structure, easy to break, and easy deliquescence, etc., and achieve the effect of rapid dispensing and reducing deliquescence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical solutions and beneficial effects of the present invention clearer, the implementation manners of the present invention will be further explained in detail below.

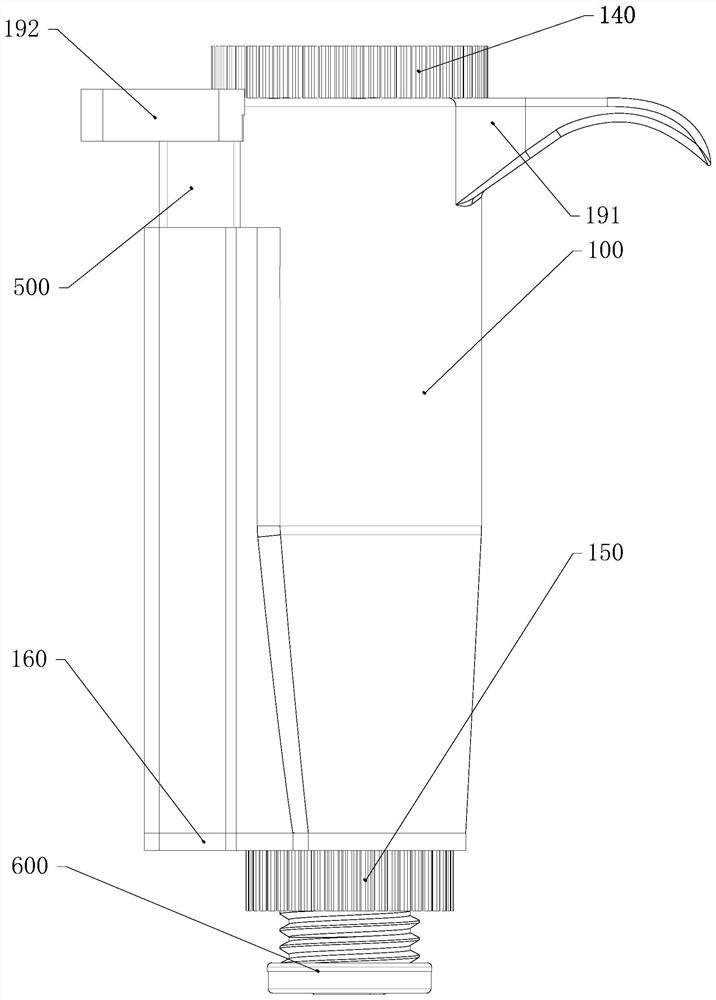

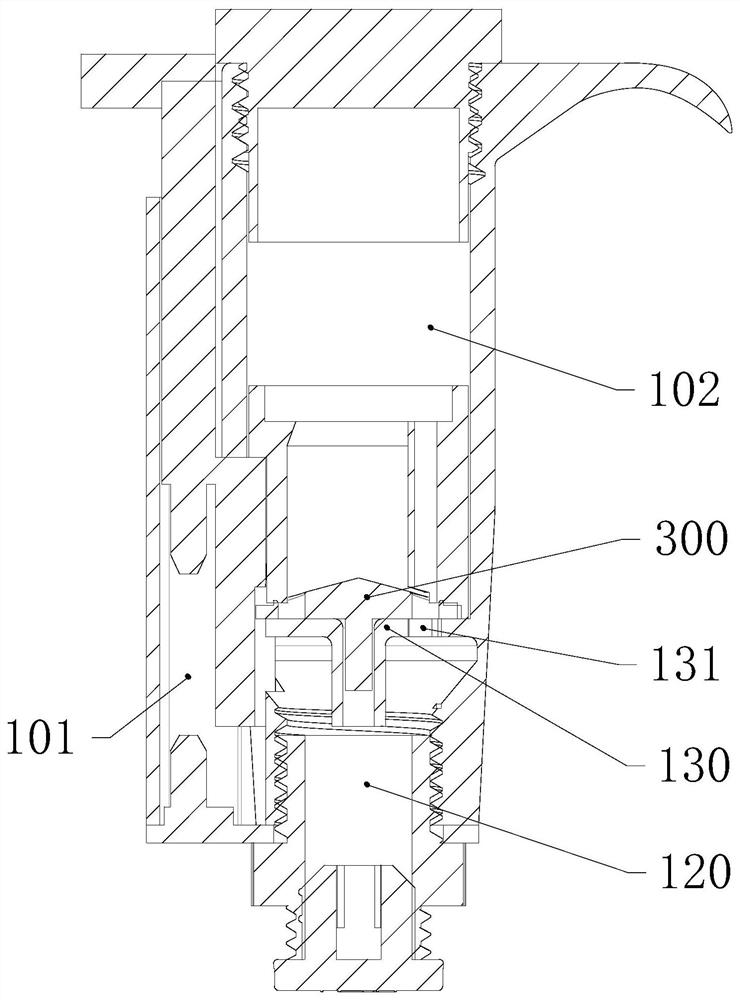

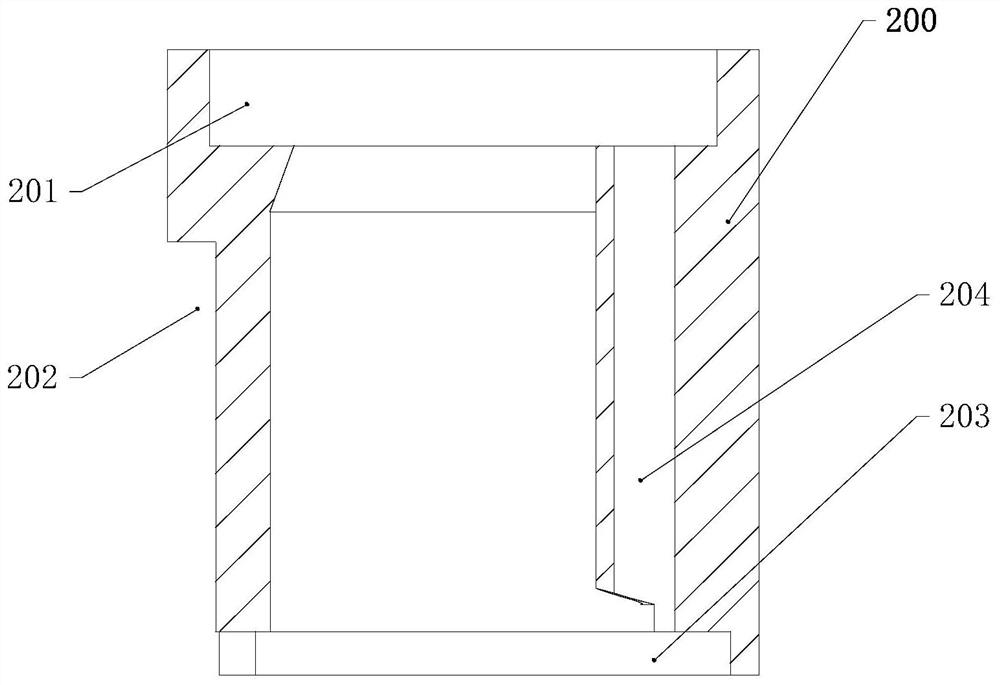

[0047]A freeze-dried microchip dispenser includes a casing 100, the casing 100 is provided with a storage chamber 102, an outlet chamber 120 and an operation chamber 101. The storage chamber 102 is used to store the freeze-dried microchips, the export chamber 120 is used to export the freeze-dried microchips, and the operating chamber 101 is provided with a driving mechanism to drive the subpackaging plate 300 to rotate, thereby realizing the subpackaging of the freeze-dried microchips.

[0048] The storage chamber 102 , the outlet chamber 120 and the operating chamber 101 can be integrally formed, or can be formed by assembling parts of the housing 100 . Such as figure 2 with 16 As shown, the main body shape of the housing 100 is a long cylinder, the storage chamber 102 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com