Sound equipment assembling and conveying assembly line

An assembly line and sound technology, which is applied in assembly machines, conveyor objects, transportation and packaging, etc., can solve the problems of high cost and large area of horizontal conveying devices, and achieve the effect of reducing assembly area and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

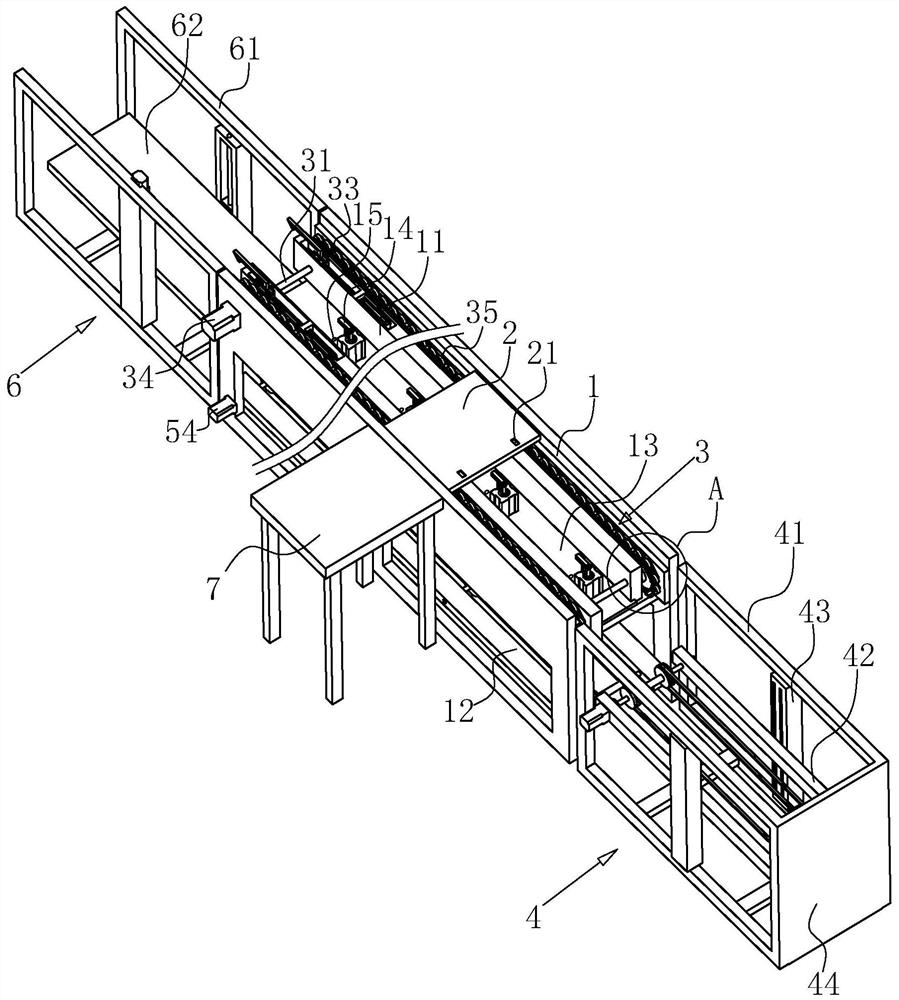

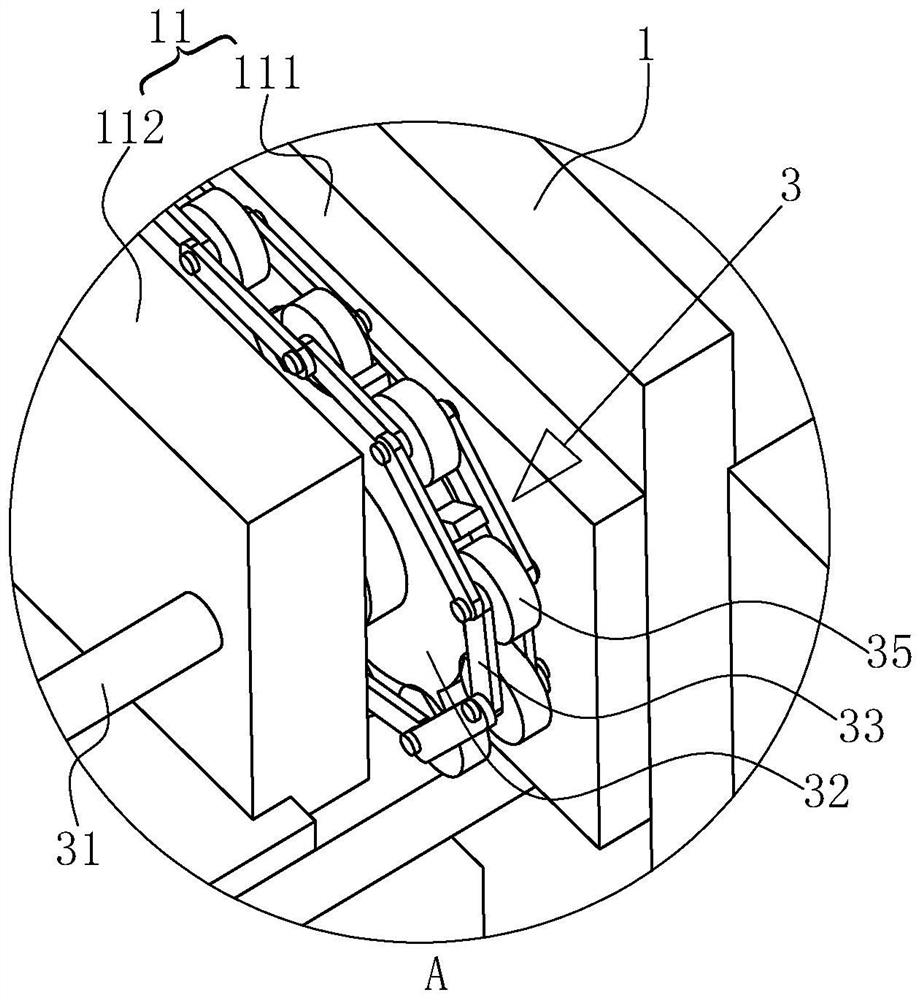

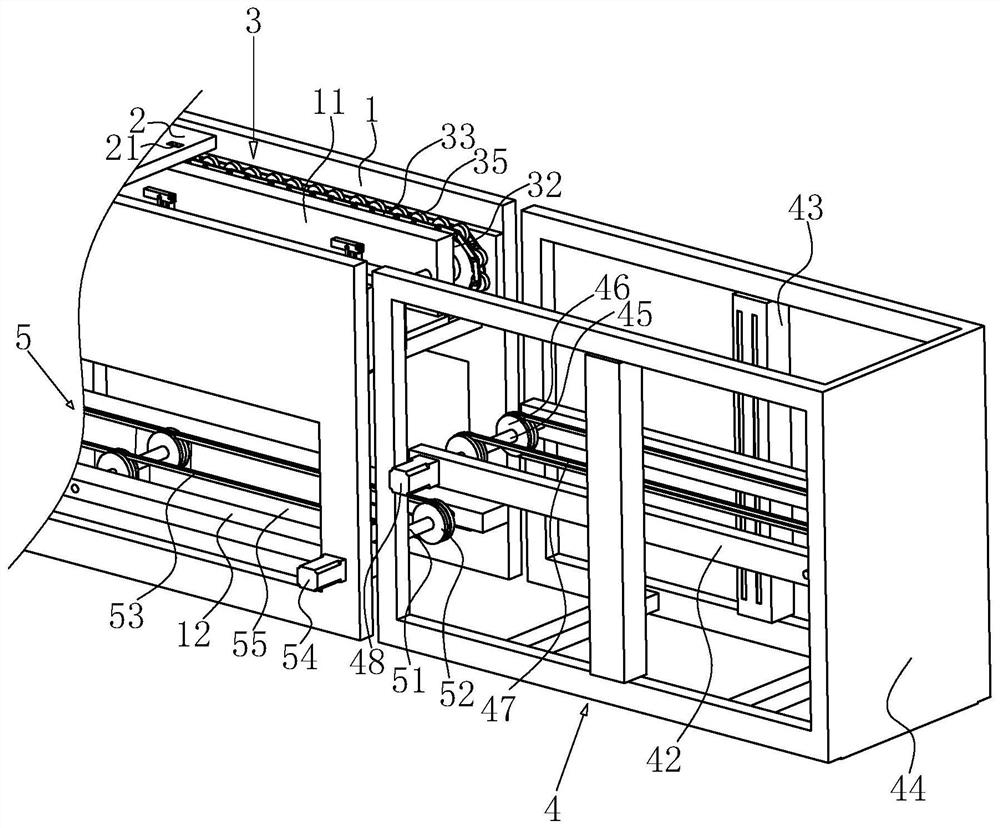

[0036] The following is attached Figure 1-5 The application is described in further detail.

[0037] The embodiment of the present application discloses an audio assembly and transmission line. refer to figure 1 , the audio assembly transmission line includes a frame 1, the frame 1 extends horizontally, and the opposite sides of the frame 1 in the length direction are fixedly installed with receiving rails 11, and the receiving rails 11 extend toward the length direction of the frame 1; One side of the 1 is provided with work stations 7 at equal intervals along the length direction of the receiving track 11; The opposite sides in the direction are abutted against the top surface of the receiving rail 11, so that when the transportation board 2 moves to the position corresponding to the station 7 in the length direction of the receiving rail 11, it can be placed on the transportation board 2 to be assembled. Semi-finished products are assembled.

[0038] refer to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com