Chimney top soot prevention structure

A chimney and soot technology, which is applied in the directions of climate sustainability, human health protection, combustion methods, etc., can solve the problems of soot falling and affect the environment, and achieve the effect of avoiding the increase of the windward area, facilitating centralized treatment and increasing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

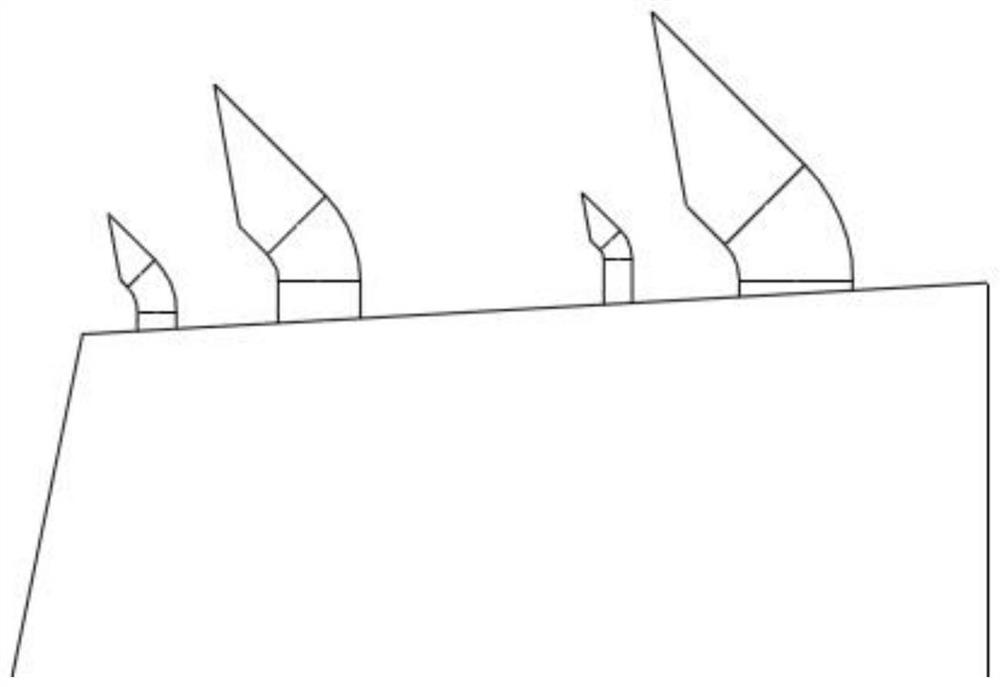

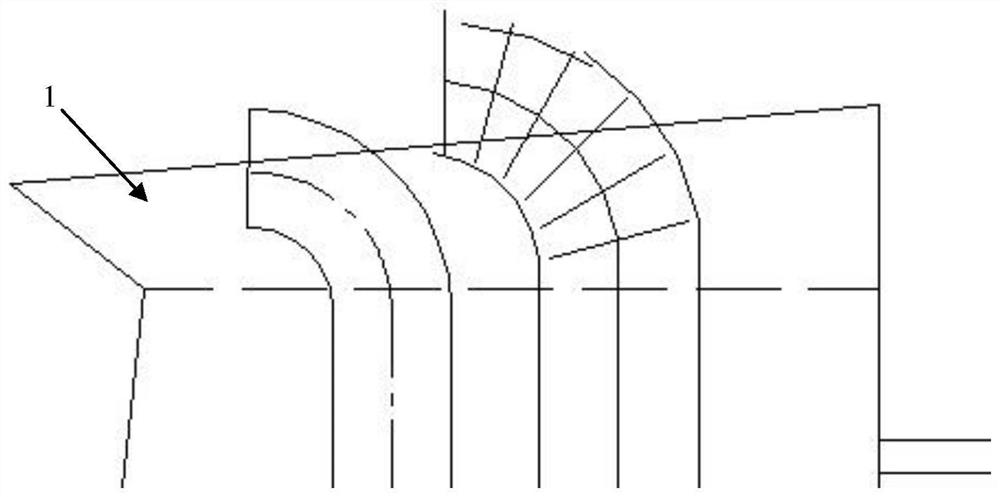

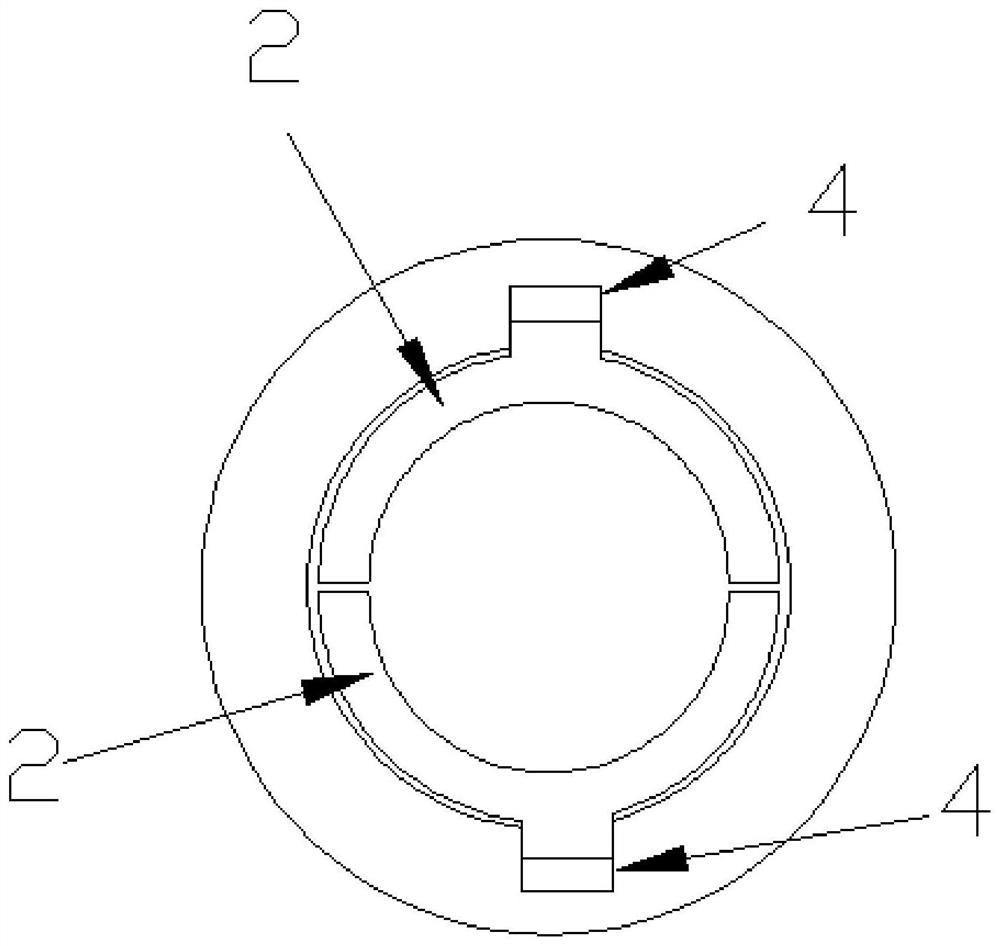

[0018] like Figure 2 to Figure 5 shown (for ease of illustration, figure 1 Soot collection rings, inclined plates, inserts, and dust baffles are not shown; Figure 4 The dotted line in the middle indicates the state schematic diagram when the swash plate is retracted, Figure 4 Dust baffle is not shown), the present invention is a chimney top anti-soot structure, including the chimney rear wall 1 inclined to the horizontal plane; The lower end of 1 is provided with a sloping plate 3 for preventing soot from falling into the living area and for accommodating the soot collection ring 2 . The soot collection ring 2 includes two half rings, one end of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com