Copper foil tension testing device

A tensile test, copper foil technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc., can solve problems such as crushing copper foil, inaccurate test results, scratches, etc., to ensure that Accuracy, better clamping effect, enhanced fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

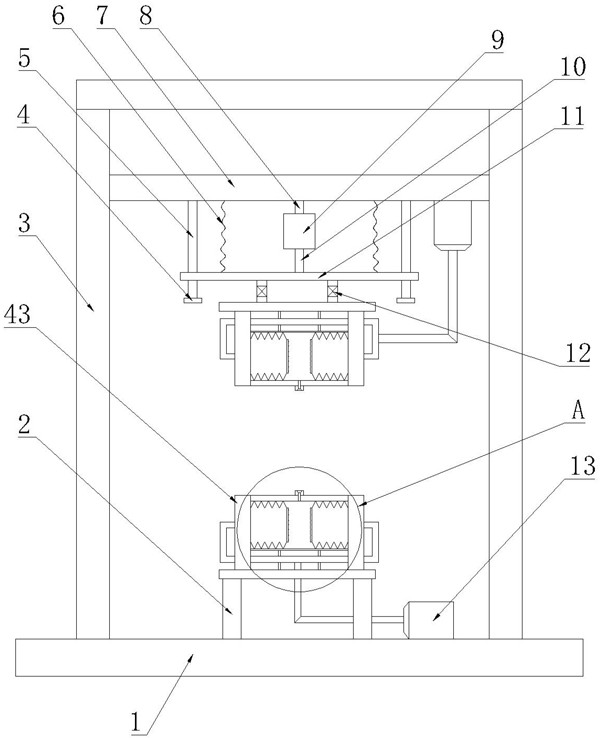

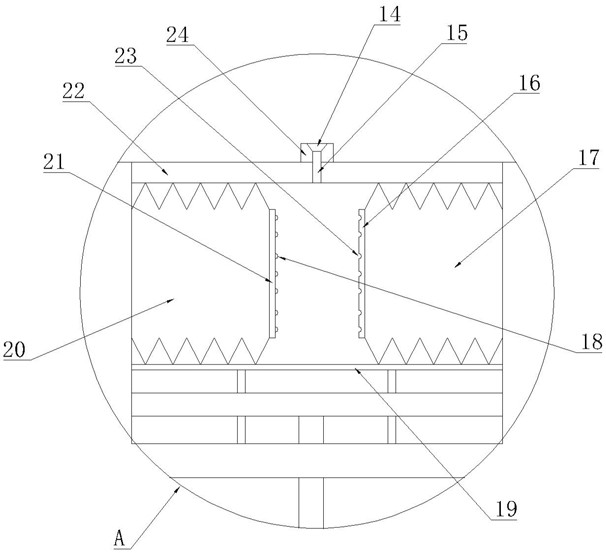

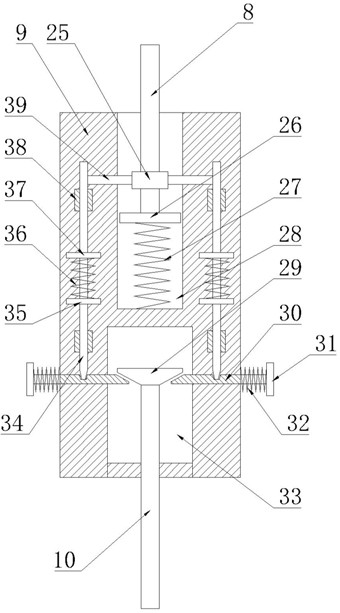

[0029] Specific embodiments of the present invention such as Figure 1-4 As shown, a copper foil tensile test device includes a base plate 1, a lifting plate 7 and a stand 3, the stand 3 is arranged on the base plate 1, and the stand 3 is provided with a vertical lead screw, The lifting plate 7 is threadedly matched with the lead screw, and the rotation of the screw drives the lifting plate 7 to move up and down on the stand 3, and also includes two airbag clamps and an overload protection assembly;

[0030] The base plate 1 is provided with a mounting frame 2, the overload protection assembly is arranged on the lower end surface of the lifting plate 7, and the two airb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com