Liquid crystal display screen full-lamination jig for fertilizer applicator

A technology of liquid crystal display and lamination fixture, applied in nonlinear optics, instruments, optics, etc., can solve the problems of not easy to take out, damaged products, products easily stuck in the placement slot, etc., to avoid jamming and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

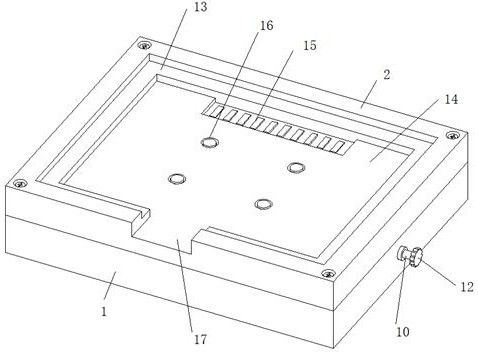

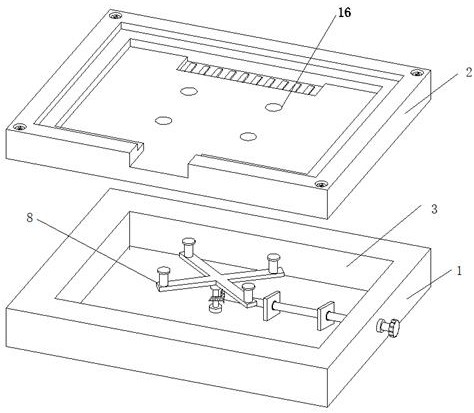

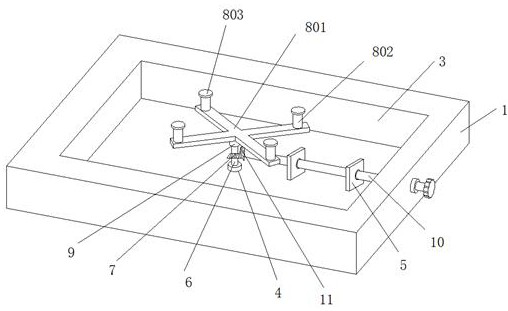

[0029] A liquid crystal display full-fit fixture for a fertilizer applicator, such as figure 1 and figure 2 As shown, including the base 1 and the jig body 2, the upper end surface of the base 1 is provided with a square groove 3, the bottom center of the square groove 3 is fixed with a bearing seat 4 and a bearing frame 5, and the upper end of the bearing seat 4 is rotatably installed with a The first rotating shaft 6, the outer wall of the middle part of the first rotating shaft 6 is fixed with a driven gear 7, the outer wall of the top of the first rotating shaft 6 is provided with a thread groove and a screw sleeve 9 is threadedly installed, and the top of the screw sleeve 9 is fixed with a jacking assembly 8; Bearing frame 5 is equipped with second rotating shaft 10, and the left end of second rotating shaft 10 is fixed with driving gear 11, and driving gear 11 and driven gear 7 are bevel gears and are connected by meshing between them, the right end of second rotating s...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 4 As shown, the jacking assembly 8 also includes return springs 804. The number of return springs 804 is four and their bottom ends are respectively fixed on the middle positions of the upper end faces of the four horizontal rods. The top ends of the return springs 804 are all fixed on the jig body 2's lower end face.

[0034] In this embodiment, the return spring 804 is squeezed when the jacking assembly 8 rises, which can prevent the horizontal frame 801 from hitting the jig body 2. When the jacking assembly 8 descends, the return spring 804 has a rebound force, thereby preventing the jacking Component 8 is stuck when moving down.

Embodiment 3

[0036] On the basis of Example 2, such as Figure 5 As shown, a handle groove 18 is provided on the left side wall of the base 1, and a handle mounting seat 19 is installed in rotation inside the handle groove 18, and an arc-shaped handle 20 is mounted on the handle mounting seat 19.

[0037] In this embodiment, when the jig needs to be moved, the arc-shaped handle 20 can be rotated out, and the hand-held handle 20 can be carried and transferred. When the jig is attached, the arc-shaped handle 20 can be stored inside the handle groove 18 , taking up no space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com