Jig frame remote monitoring system and monitoring method based on industrial Internet

A technology of remote monitoring and tire support, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as poor utilization rate, low data reliability, real-time monitoring and statistics difficulties, and reduce access pressure, Effects of Support Migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

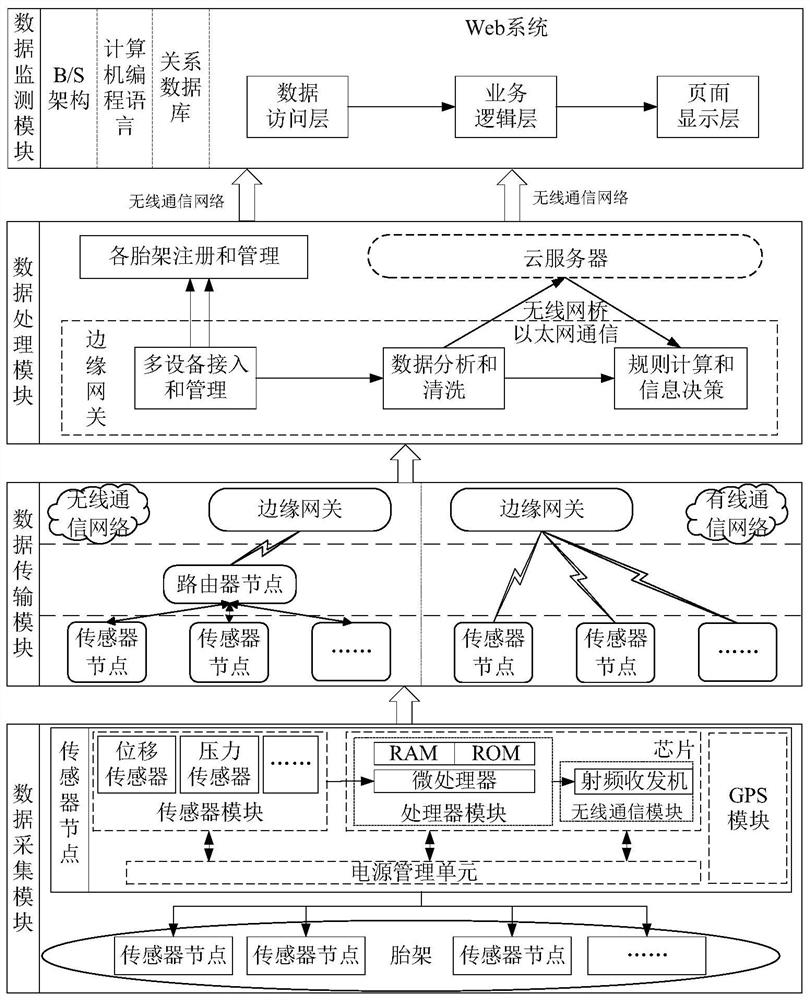

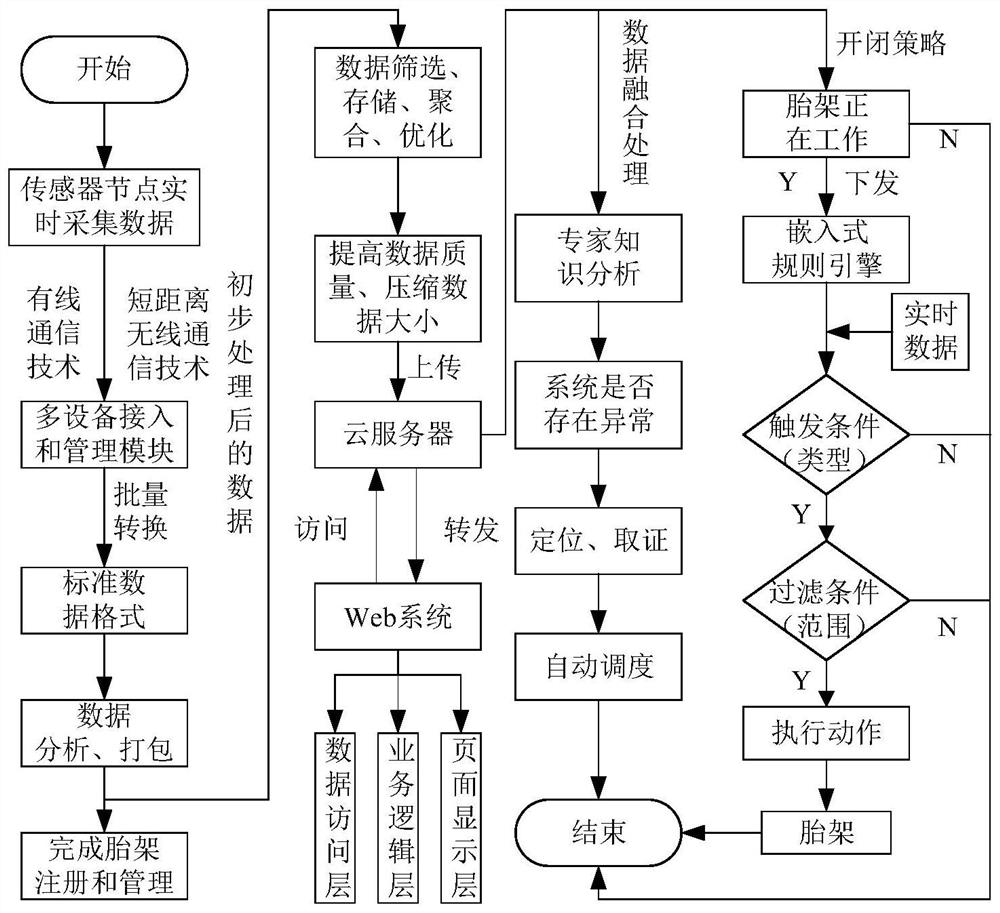

[0027] Such as figure 1 As shown, a remote tire frame monitoring system based on the industrial Internet in this embodiment includes a data acquisition module, a data transmission module, a data processing module, and a data monitoring module. The data acquisition module is the basis of the tire frame remote monitoring system, including A number of sensor nodes, the sensor nodes are arranged at various parts of the tire frame to collect various working data of the tire frame, including tensile pressure, temperature, displacement and other data.

[0028] The sensor node includes a sensor module, a processor module, a wireless communication module, a GPS module and a power supply module. The sensor module is used to collect tire frame working data and perform data conversion; The data sent by the sensor node and the data sent by other sensor nodes are stored and processed; the wireless communication module is used for the communication between the sensor node and other sensor no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com