Preparation method of sodium ion transition metal oxide positive electrode material

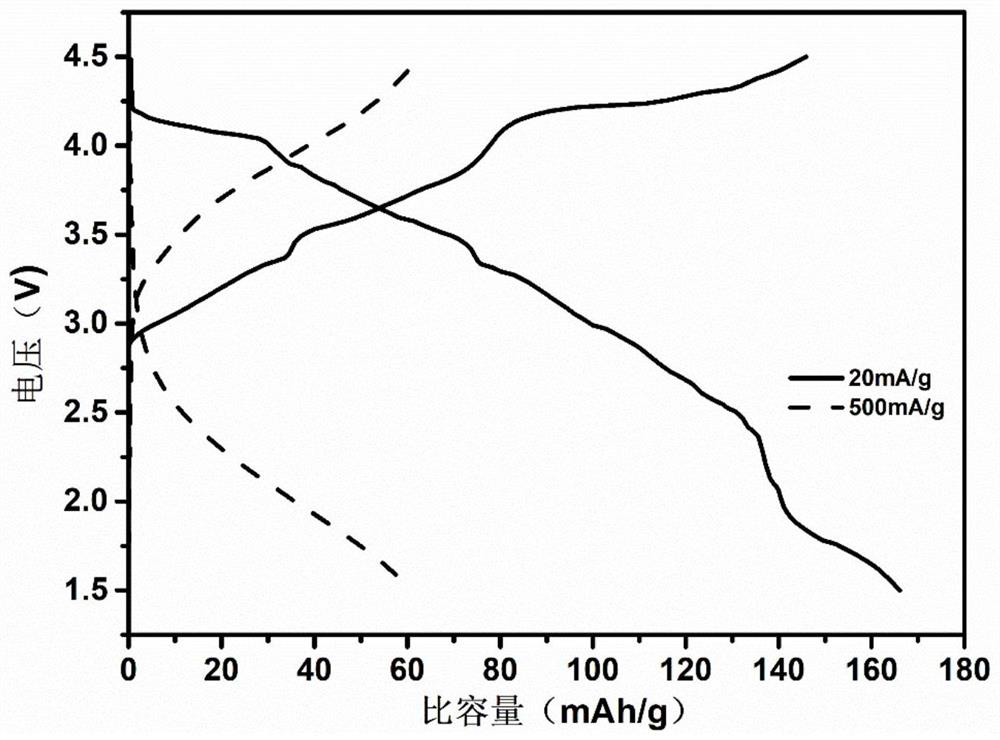

A transition metal and cathode material technology, which is applied in the field of preparation of sodium ion transition metal oxide cathode materials, can solve the problems of impairing battery cycle life and rate performance, lacking cycle performance and rate performance, and hindering the practical application of sodium ion batteries. , to achieve the effect of improving cycle stability, promoting practical application, excellent cycle performance and rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a technical solution: a method for preparing a sodium ion transition metal oxide positive electrode material, the preparation method comprising the following steps:

[0025] S1, mixing: first take out stoichiometric sodium acetate trihydrate, manganese acetate tetrahydrate, nickel acetate tetrahydrate, cobalt acetate tetrahydrate, magnesium acetate, zinc acetate dihydrate and citric acid, and uniformly dissolve them in quantitative water, then After fully stirring and dissolving, transfer to a water bath and continue stirring until gelatinous;

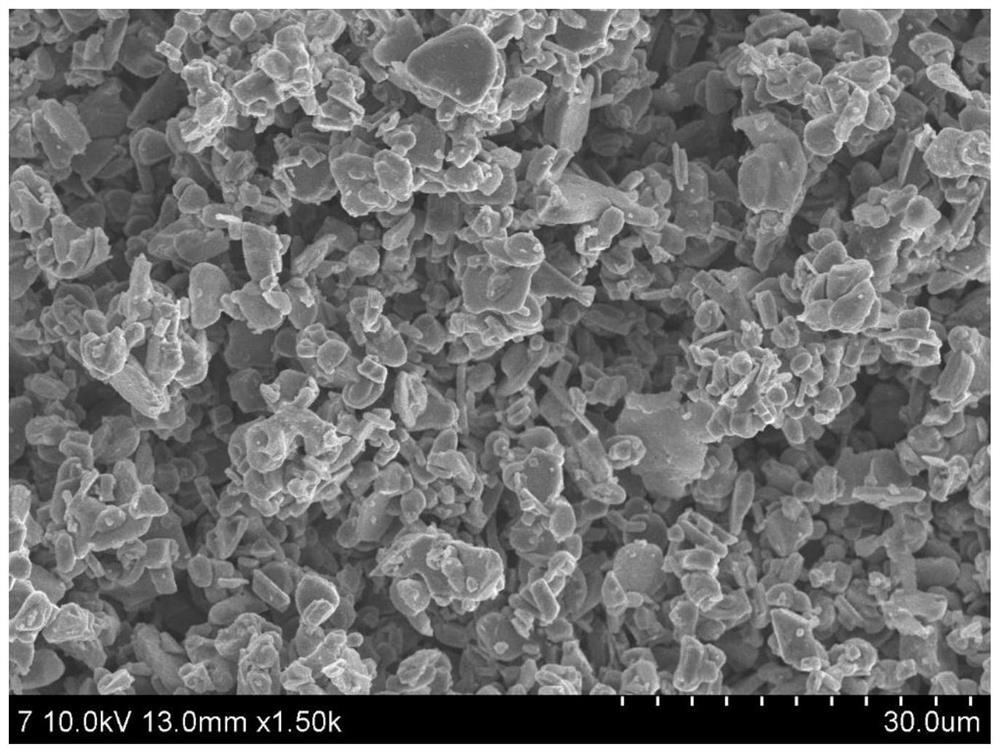

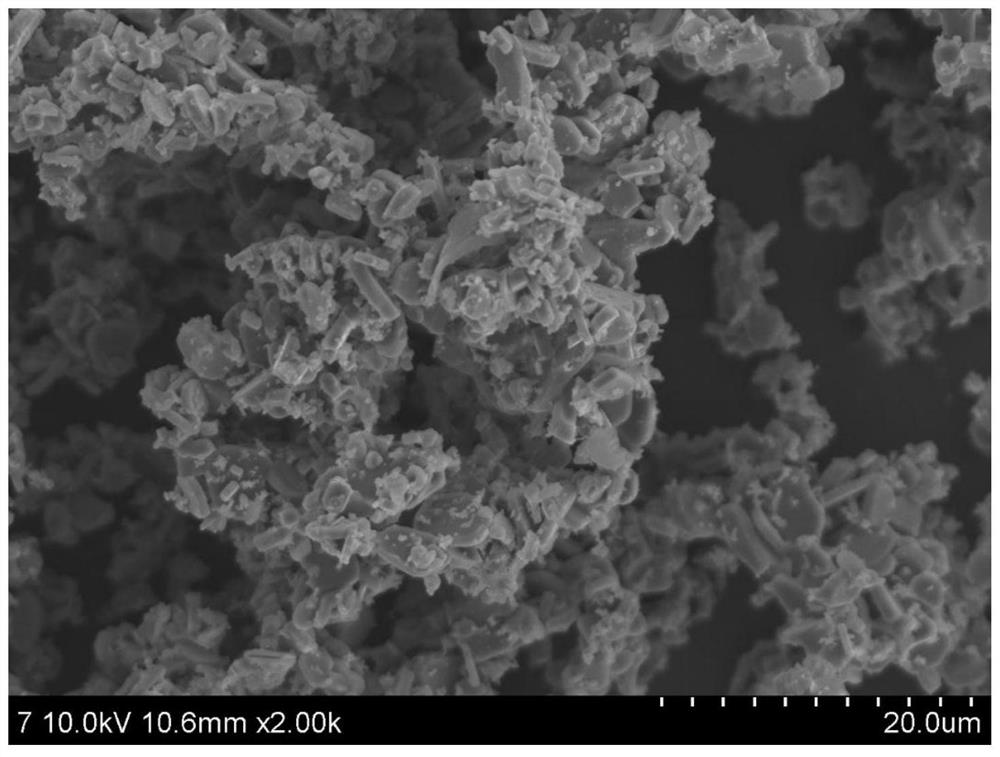

[0026] S2, grinding and firing: take out the gel material and put it in an oven for drying, then put it into an agate mortar and grind it thoroughly after drying, then put it into a muffle furnace for firing to remove the residual organic matter inside, wait After cooling, grind again, and finally continue to burn in the muffle furnace for 10 hours;

[0027] S3, Forming: After the material is cooled to ro...

example 1

[0036] The invention provides a technical solution: a chemical fiber composite material and a preparation method thereof, the preparation method comprising the following steps:

[0037] S1, mixing: first take out stoichiometric sodium acetate trihydrate, manganese acetate tetrahydrate, nickel acetate tetrahydrate, cobalt acetate tetrahydrate, magnesium acetate, zinc acetate dihydrate and citric acid, and uniformly dissolve them in quantitative water, then After fully stirring and dissolving, transfer to a water bath and continue stirring until gelatinous;

[0038] S2, grinding and firing: take out the gel material and put it in an oven for drying, then put it into an agate mortar and grind it thoroughly after drying, then put it into a muffle furnace for firing to remove the residual organic matter inside, wait After cooling, grind again, and finally continue to burn in the muffle furnace for 10 hours;

[0039] S3, Forming: After the material is cooled to room temperature, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com