Fault processing method and system for feeder automation line with distributed power supply access

A fault handling method and distributed power supply technology, applied in the direction of circuit devices, system integration technology, information technology support systems, etc., can solve problems such as failure to perform power failure, switch malfunction, failure to isolate faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

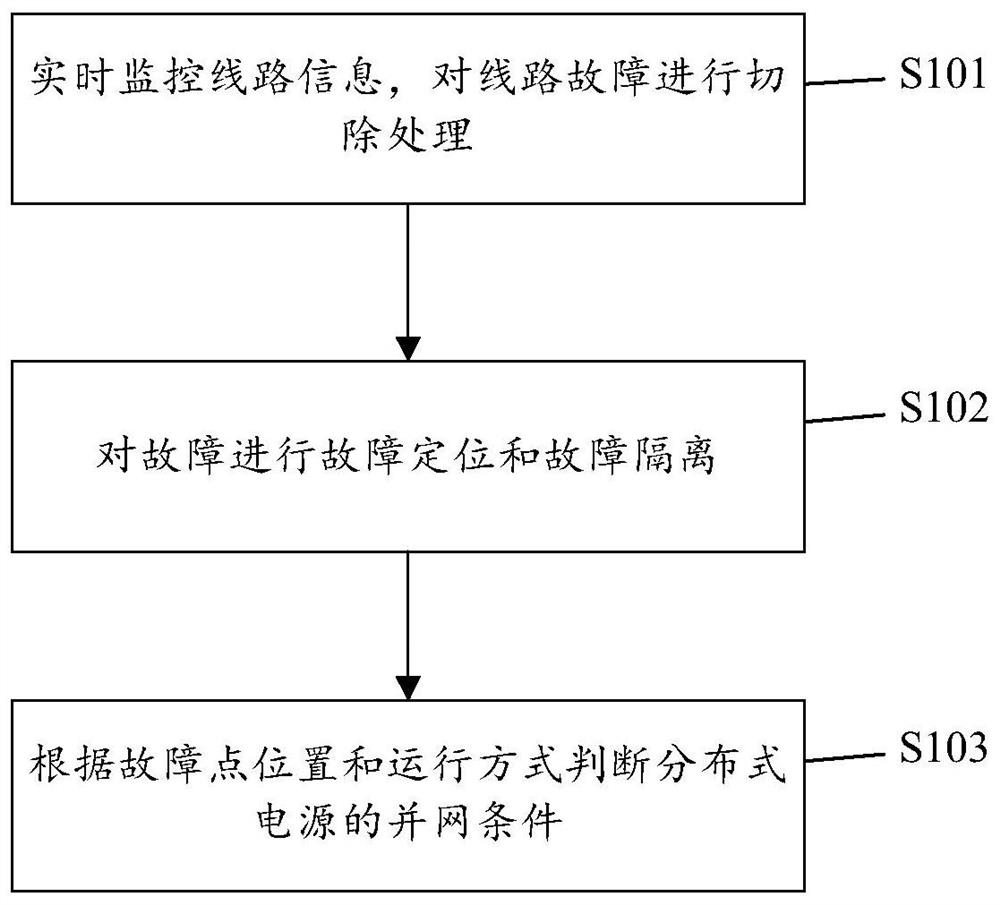

[0028] refer to figure 1 , figure 1 It is a schematic flow chart of a fault handling method for a feeder automation line with distributed power access.

[0029] Such as figure 1 As shown, a method for handling faults of feeder automation lines with distributed power access, the method includes:

[0030] S101 monitors line information in real time, and removes line faults. The automatic switch FS0 monitors the line information in real time and collects electrical characteristic quantities, including voltage, current, and frequency; the automatic switch FS0 judges the grounding or short circuit of the outgoing line according to the change characteristics of the voltage, current, and frequency when the line fails. The switch closest to the distributed power supply is automatically opened, and the distributed power supply is disconnected.

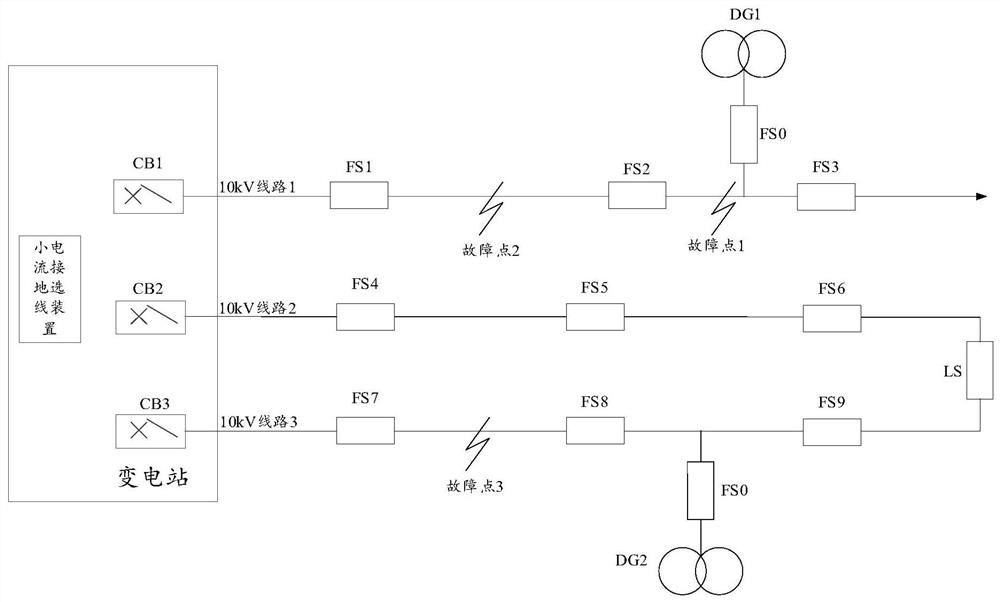

[0031] S102 Carry out fault location and fault isolation for faults; after the distributed power supply is removed from the distribution n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com