A flotation method for low-grade collophosphate ore with dense massive structure

A block-shaped, low-grade technology, applied in solid separation and other directions, can solve the problems of large fluctuation of flotation index and large consumption of flotation reagents, and achieve the effect of reducing reagent consumption and improving flotation and sorting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

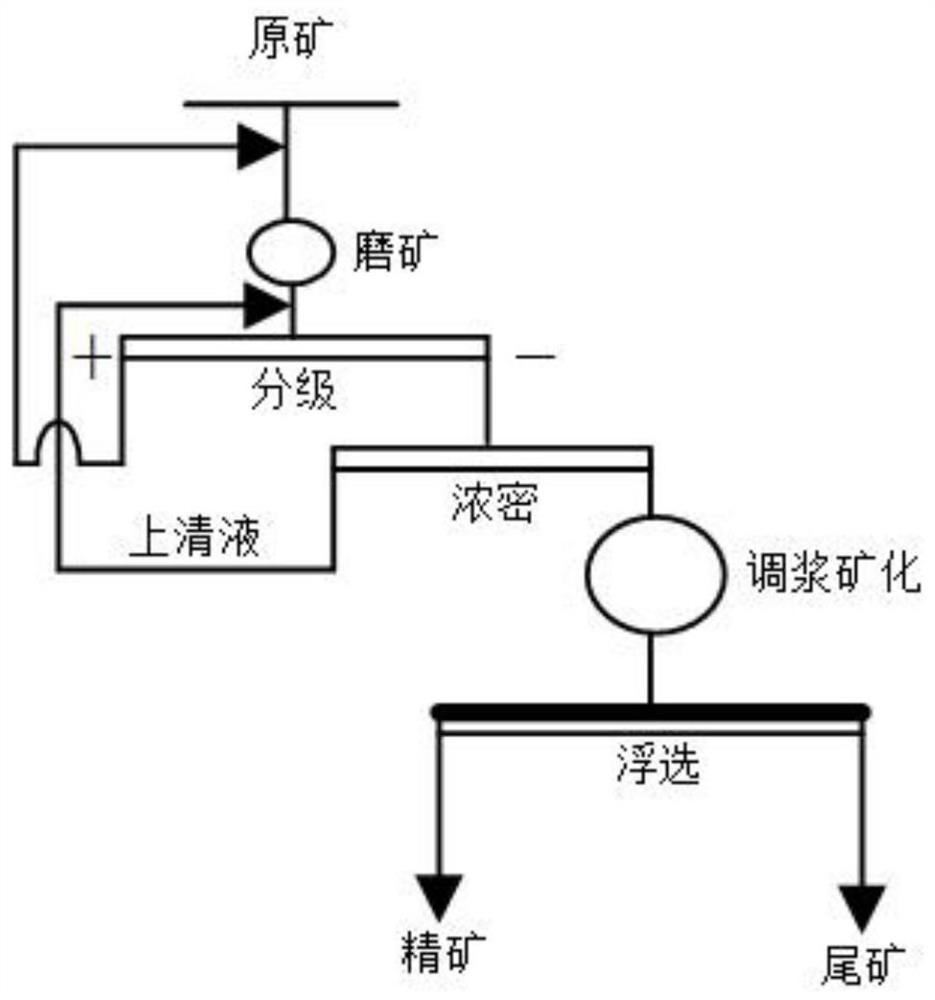

[0025] For the collophosphate rock with dense block structure accounting for 60%, stripe structure accounting for 30%, and other structure types accounting for 10%, P 2 O 5 Content 21%~22%, MgO content 5%~6%, MgO / P 2 O 5 =0.167~0.50, SiO 2 The content is 13% to 15%, and the crushing ratio is greater than 60.

[0026] Mineral monomer dissociation is achieved through multi-stage crushing and grinding, and the pulp concentration is controlled to be 20% to 24%. Swirl classification is carried out on the pulp, and the content of the classification overflow fineness-0.074mm is 75-85%. The graded bottom flow sediment is returned to the mill for regrinding, and the sand return ratio is 300% to 350%.

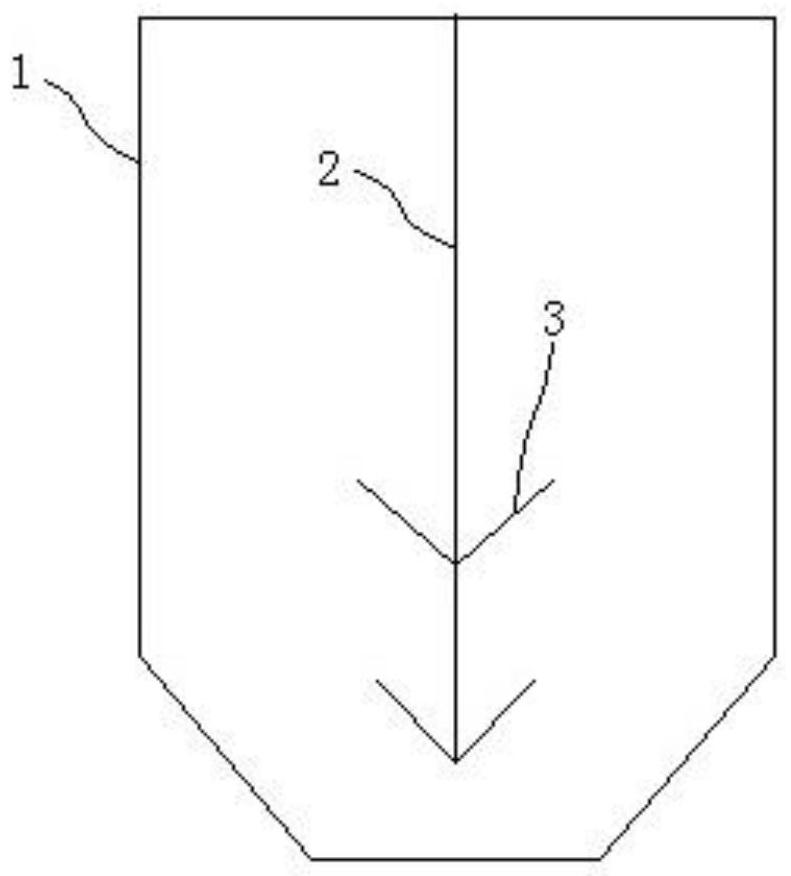

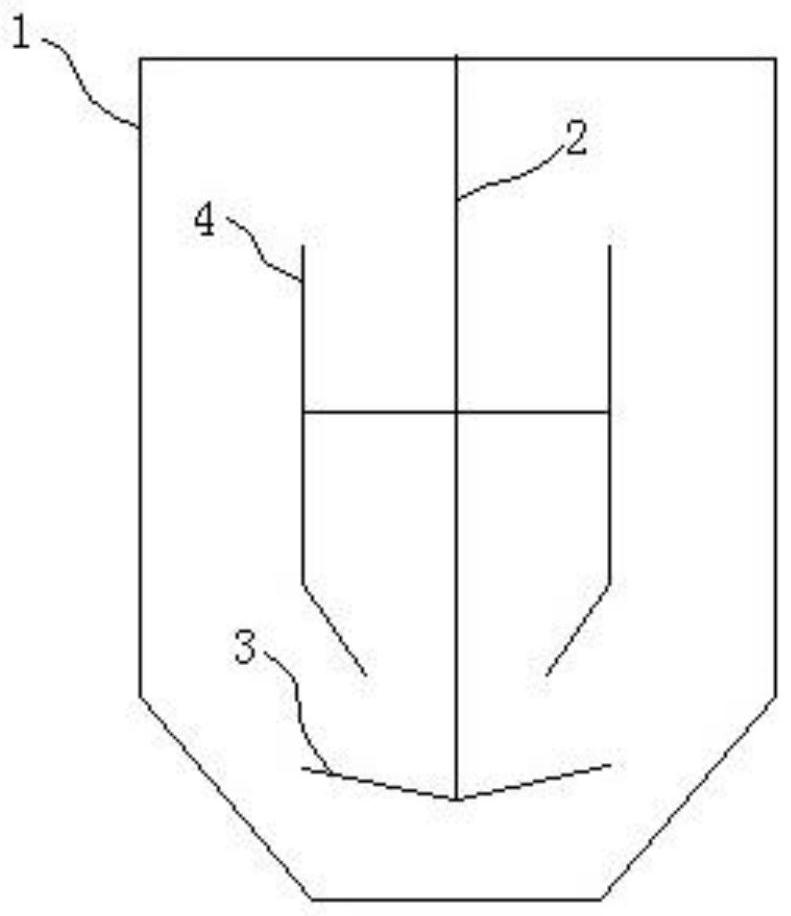

[0027] The classification overflow is concentrated by a cyclone, and the inlet pressure of the cyclone is set to 0.1-0.15MPa. The dense ore pulp with a concentration of 26% to 28% is obtained, and the dense ore pulp is fed into the primary sizing tank, and inorganic acid is added t...

Embodiment 2

[0030] For the collophosphate rock with dense block structure accounting for 40%, stripe structure accounting for 40%, and other structure types accounting for 20%, P 2 O 5 Content 21%~22%, MgO content 5%~6%, MgO / P 2 O 5 =0.167~0.50, SiO 2 The content is 13% to 15%, and the crushing ratio is greater than 60.

[0031] Mineral monomer dissociation is achieved through multi-stage crushing and grinding, and the pulp concentration is controlled to be 20% to 25%. Swirl classification is carried out on the pulp, and the content of the classification overflow fineness-0.074mm is 85-95%. The graded bottom flow sediment is returned to the mill for regrinding, and the sand return ratio is 320% to 380%.

[0032] The classification overflow is concentrated by a cyclone, and the inlet pressure of the cyclone is set to 0.1-0.15MPa. The dense ore pulp with a concentration of 28% to 30% is obtained, the dense ore pulp is input into the primary sizing tank, the mineral acid is added for 0...

Embodiment 3

[0035] For the collophosphate rock with dense block structure accounting for 50%, stripe structure accounting for 30%, and other structure types accounting for 20%, P 2 O 5 Content 21%~22%, MgO content 5%~6%, MgO / P 2 O 5 =0.167~0.50, SiO 2 The content is 13% to 15%, and the crushing ratio is greater than 60.

[0036] Mineral monomer dissociation is achieved through multi-stage crushing and grinding, and the pulp concentration is controlled to be 20% to 25%. Swirl classification is carried out on the pulp, and the content of the classification overflow fineness-0.074mm is 80-85%. The graded bottom flow sediment is returned to the mill for regrinding, and the sand return ratio is 300% to 400%.

[0037]The classification overflow is concentrated by a cyclone, and the inlet pressure of the cyclone is set to 0.1-0.15MPa. The dense ore pulp with a concentration of 28% to 30% is obtained, the dense ore pulp is input into the primary sizing tank, the mineral acid is added for 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com