A method for explosive welding of tungsten foil

A technology of explosive welding and explosives, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as infeasibility, prevent fracture and surface damage, avoid ablation and damage, and prevent fracture and ablation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

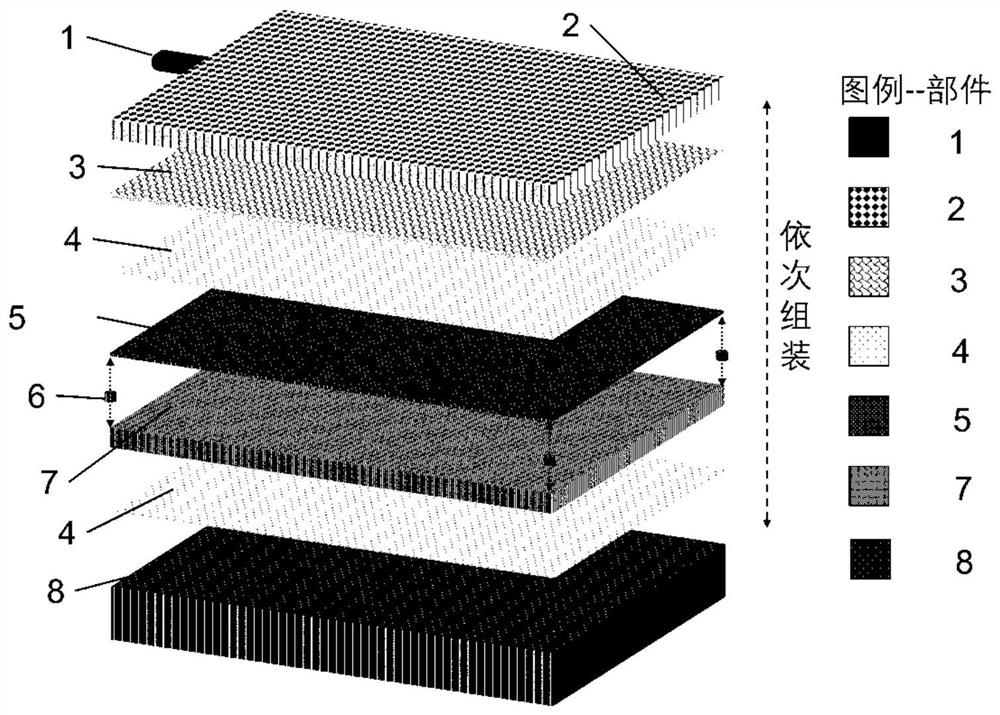

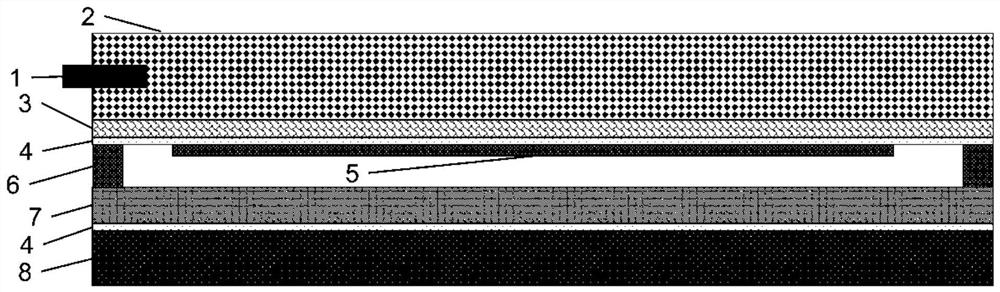

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

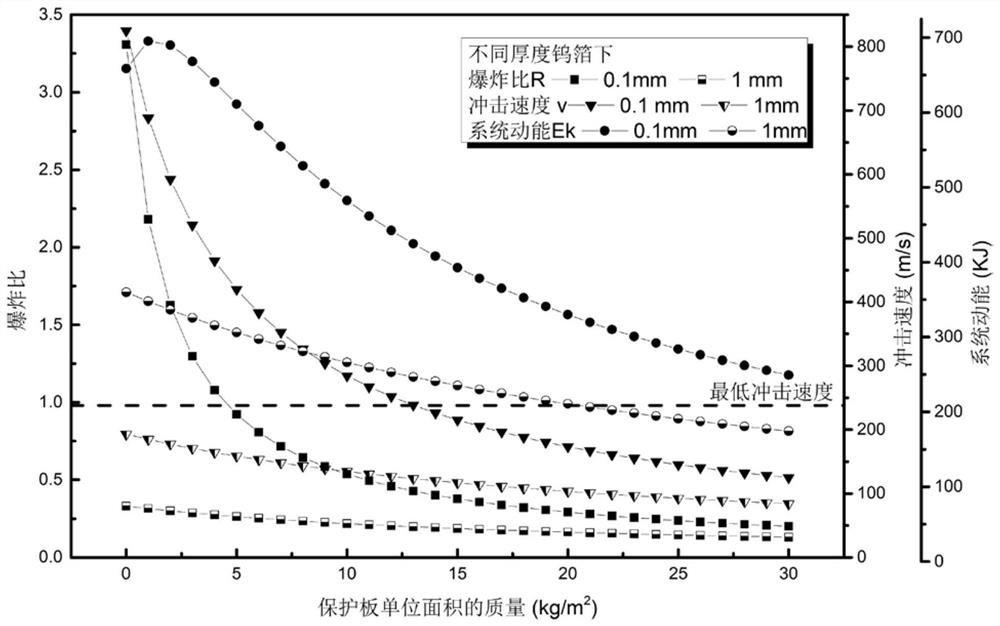

[0039] In traditional welding, no bonding material 4 (such as double-sided tape bonding) is used to bond the protective plate 3 and the cover plate 5 , the cover plate is tungsten foil, and the base plate 7 and the cutting board 8 are bonded together. Therefore, the foil material is often smashed by explosives after welding. By bonding the tungsten foil, the substrate and the protective plate 3 (made of aluminum, copper, etc.), the welding of the tungsten foil and the metal plate of 0.05mm-0.4mm can be realized after using the protective plate. The difficulty of the process is that the foil material used cannot be explosively welded intact, because the ablation and shock wave after the explosion of the explosive will destroy the material. In the present invention, the tungsten foil is glued to the protective plate, which can avoid ablation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com