Repairing method for aluminum panel honeycomb sandwich structure super-large-area debonding

A honeycomb interlayer, super-large area technology, applied in household appliances, other household appliances, household components, etc., can solve the damage to the non-debonded sandwich structure parts, the poor fit between the aluminum panel and the repair surface, and the failure of the sandwich structure. Meet non-destructive testing and appearance testing requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for repairing super-large-area debonding of an aluminum panel honeycomb sandwich structure, comprising the following steps:

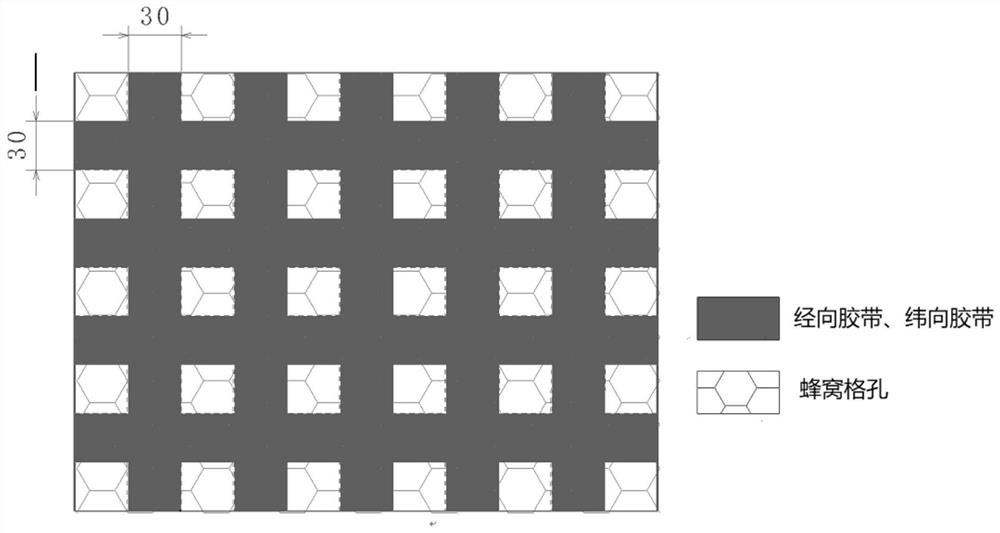

[0042] Step 1: Divide the debonding area of the aluminum panel honeycomb sandwich structure into multiple repair units;

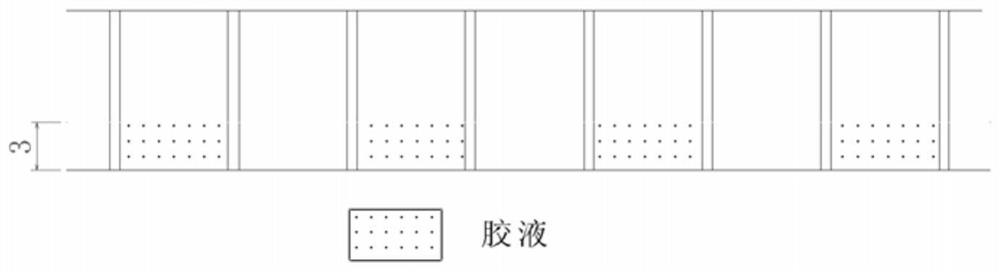

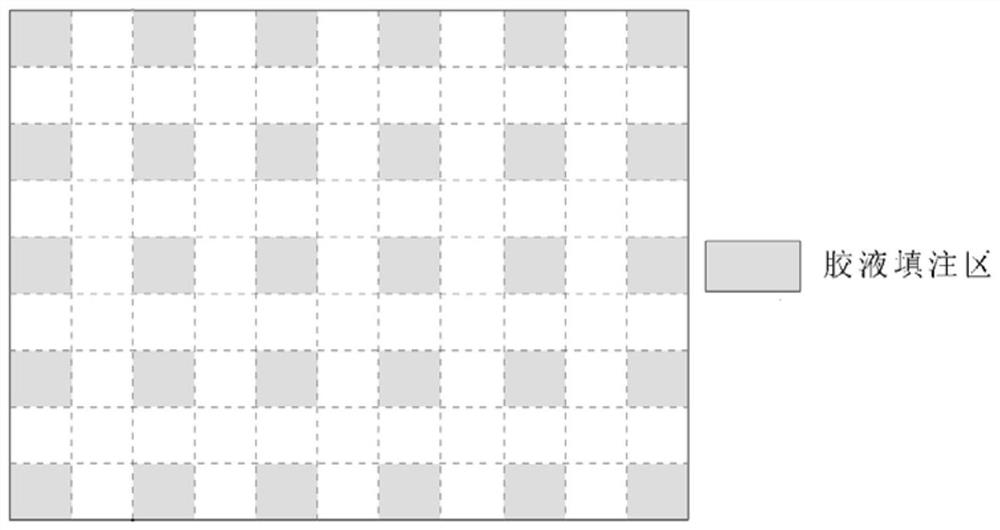

[0043] Step 2: inject the repair glue into the honeycomb cells of the repair unit multiple times and solidify;

[0044] Step 3: Lay the aluminum panel and adhesive film on the debonded area of the honeycomb sandwich structure of the aluminum panel, and conduct non-destructive testing during the laying process;

[0045] Step 4: Curing the debonded area of the honeycomb sandwich structure of the aluminum panel to complete the repair.

[0046] Another embodiment of the present invention: before step 1, the surface of the debonding area of the honeycomb sandwich structure of the aluminum panel is treated, specifically: removing the aluminum panel in the debonding area of the honeycomb sandwich structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com