High-glossiness laser glitter powder and production process therefor

A high gloss, production process technology, applied in decorative arts, special decorative structures, etc., can solve the problems of laser glitter powder falling off, poor decorative effect, bursting and falling off, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

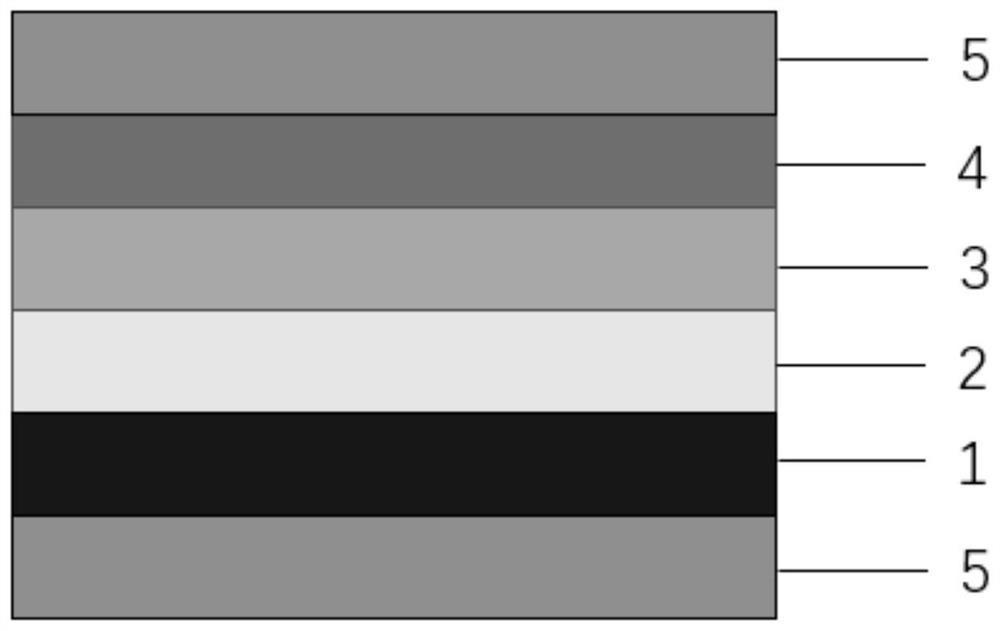

[0031] A high-gloss laser glitter powder with a particle size of less than 0.05mm, including a PET base film 1, a two-component high-temperature and high-pressure resistant coating 2 disposed on the PET base film 1, and a two-component high-temperature and high-pressure resistant coating disposed on the two-component high-temperature and high-pressure coating The double-pressed laser textured layer 3 on the 2, and the aluminum-coated layer 4 arranged on the double-pressed laser textured layer 3, the side of the aluminum-coated layer 4 facing away from the double-pressed laser textured layer 3 and the PET base film 1 away from the double-pressed laser textured layer 3 One side of the component high temperature and high pressure resistant coating 2 is provided with a silicone oil layer.

[0032] In this embodiment, the PET base film 1 has a thickness of 16 μm, a glossiness greater than 165%, a haze less than 2%, and a light transmittance greater than 88%. The choice of high-tran...

Embodiment 2

[0042]A high-gloss laser glitter powder with a particle size of less than 0.05mm, including a PET base film 1, a two-component high-temperature and high-pressure resistant coating 2 disposed on the PET base film 1, and a two-component high-temperature and high-pressure resistant coating disposed on the two-component high-temperature and high-pressure coating The double-pressed laser textured layer 3 on the 2, and the aluminum-coated layer 4 arranged on the double-pressed laser textured layer 3, the side of the aluminum-coated layer 4 facing away from the double-pressed laser textured layer 3 and the PET base film 1 away from the double-pressed laser textured layer 3 One side of the component high temperature and high pressure resistant coating 2 is provided with a silicone oil layer 5 .

[0043] In this embodiment, the PET base film 1 has a thickness of 14 μm, a glossiness greater than 165%, a haze less than 2%, and a light transmittance greater than 88%. The choice of high-tr...

Embodiment 3

[0053] A high-gloss laser glitter powder with a particle size of less than 0.05mm, including a PET base film 1, a two-component high-temperature and high-pressure resistant coating 2 disposed on the PET base film 1, and a two-component high-temperature and high-pressure resistant coating disposed on the two-component high-temperature and high-pressure coating The double-pressed laser textured layer 3 on the 2, and the aluminum-coated layer 4 arranged on the double-pressed laser textured layer 3, the side of the aluminum-coated layer 4 facing away from the double-pressed laser textured layer 3 and the PET base film 1 away from the double-pressed laser textured layer 3 One side of the component high temperature and high pressure resistant coating 2 is provided with a silicone oil layer 5 .

[0054] In this embodiment, the PET base film 1 has a thickness of 18 μm, a glossiness greater than 165%, a haze less than 2%, and a light transmittance greater than 88%. The choice of high-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com