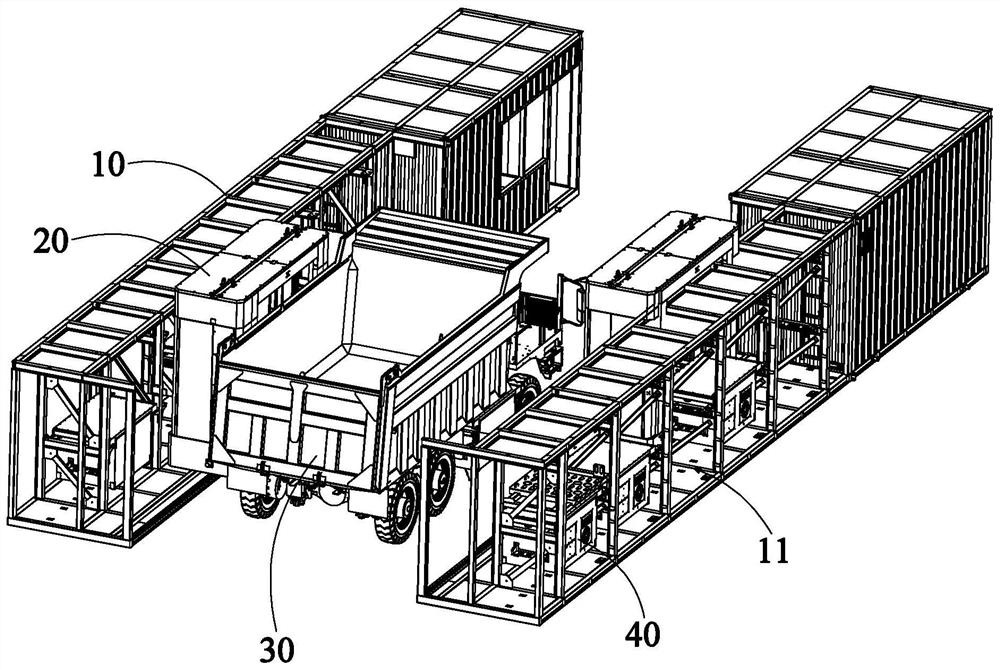

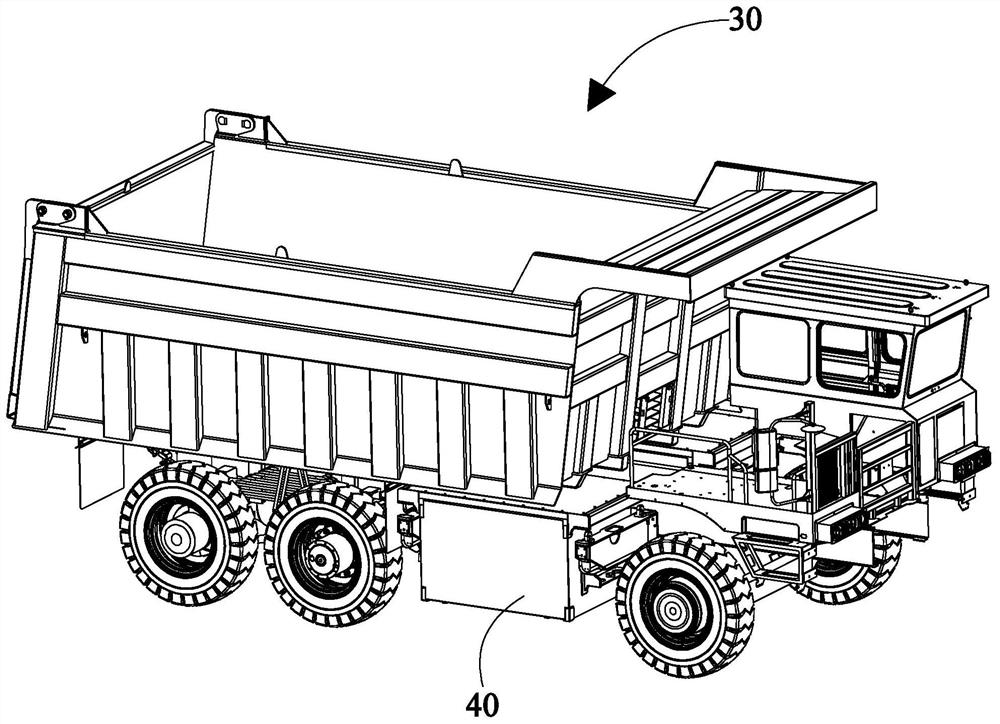

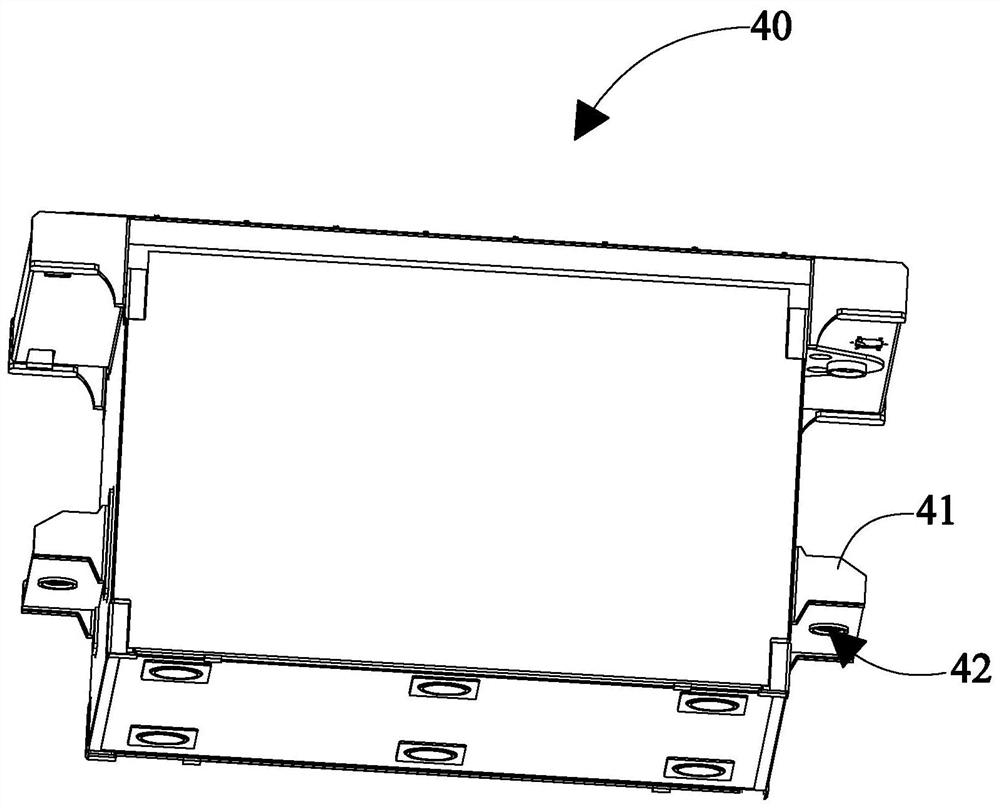

Heavy-load battery replacing robot, battery replacing method and battery replacing system

A battery-swapping robot and battery box technology, which can be used in charging stations, electric vehicles, transportation and packaging, etc., and can solve the problems of inconsistent telescopic strokes of battery-swapping robots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]In order to better understand the above objects, features and advantages of the present disclosure, the present disclosure will be described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other. Many specific details are set forth in the following description to facilitate a full understanding of the present disclosure, and the described implementations are only some of the implementations of the present disclosure, but not all of the implementations. Based on the implementation manners in the present disclosure, all other implementation manners obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present disclosure.

[0052] Unless otherwise defined, all technical and scientific terms used herein have the sam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap