Fire extinguisher machining and transporting device

A technology of transport device and fire extinguisher, which is applied in the directions of transport and packaging, multi-axle trolleys, trolley accessories, etc., can solve the problems of inconvenience and inconvenience in the transportation of fire extinguisher tanks, and achieve the effects of reduced vibration, stable and efficient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

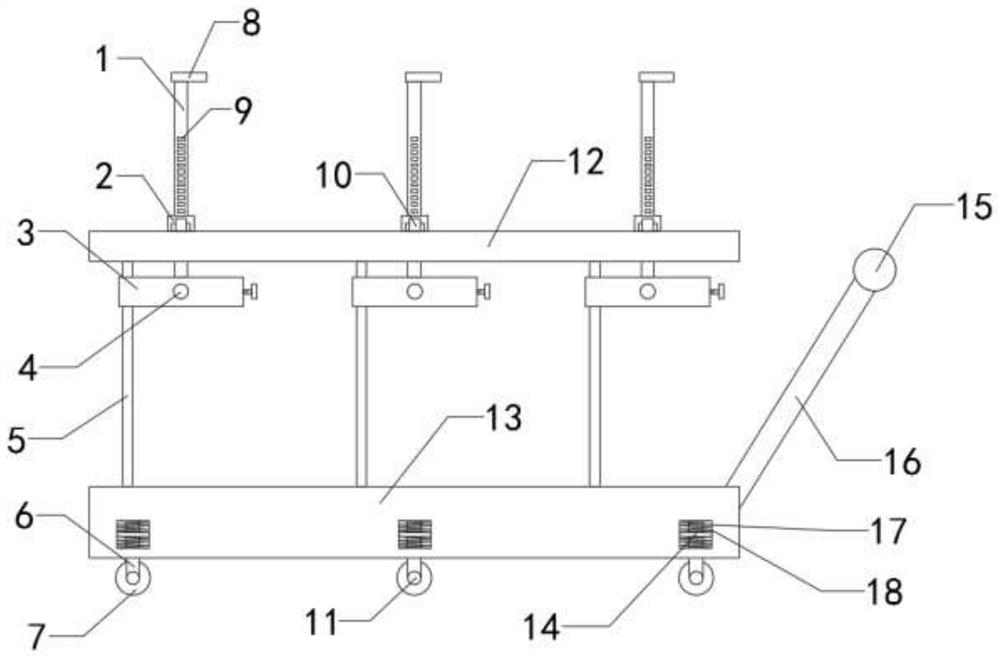

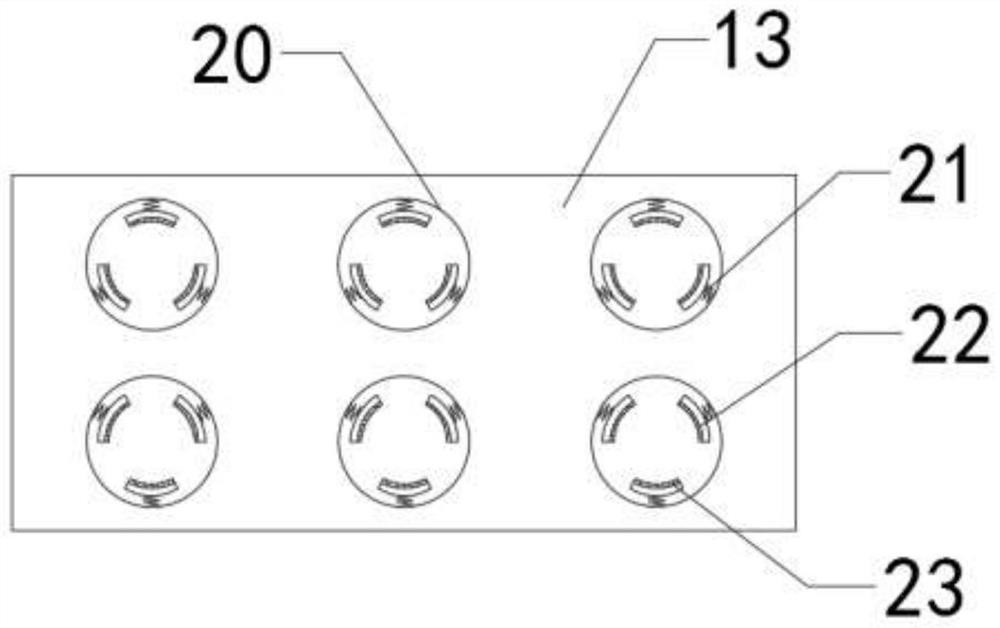

[0021] see Figure 1~4 , in an embodiment of the present invention, a fire extinguisher processing and transporting device includes a support base 13, the support base 13 is connected to a push rod 16, the push rod 16 is connected to a push handle 15, and the lower ends of the support base 13 are There are a plurality of moving wheels 7, and the fire extinguisher processing and transporting device is moved by pushing the handle 15 and the moving wheels 7. The upper end of the support base 13 is provided with a fixed transport mechanism, which is convenient for users to adjust the size of the fire extinguisher. The fire extinguisher tank is fixed for transportation.

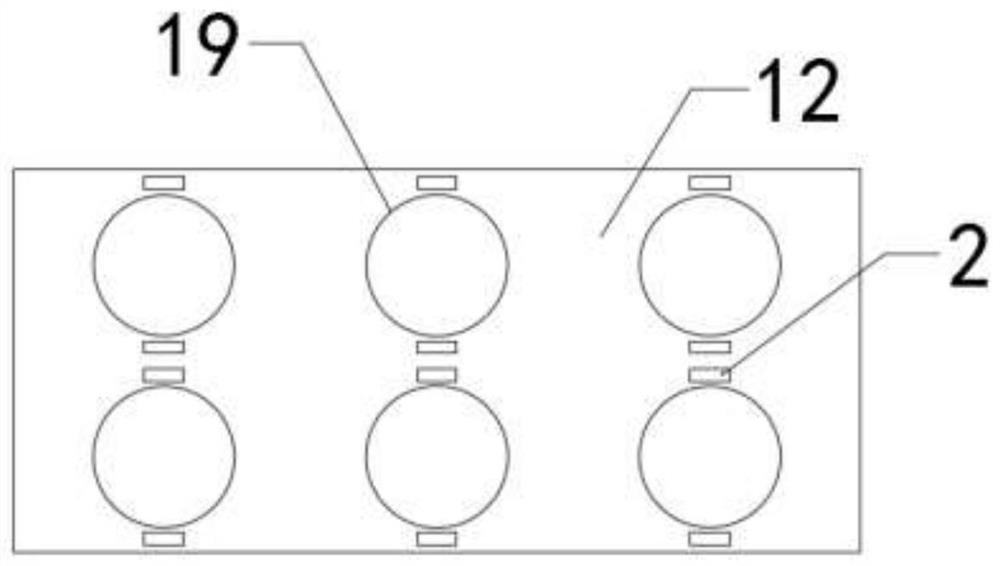

[0022] The specific form of the fixed transportation mechanism is not limited. In this embodiment, preferably, the fixed transportation mechanism includes a fixed main board 12, and a plurality of through holes 19 are symmetrically arranged on the fixed main board 12. Preferably, the The number of through holes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com